Automatic ditcher

A trencher and rack technology, applied in the field of agricultural machinery, can solve problems such as high labor intensity, and achieve the effects of reducing labor intensity, automation of operations, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

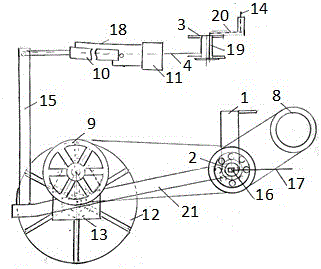

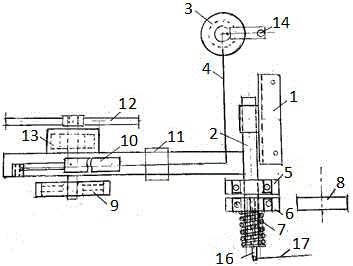

[0012] Such as figure 1 , 2 As shown, the automatic ditching machine includes a connecting piece 1, a frame cross shaft 2, a passive disc 5, a driving disc 6, a pressure spring 7, a transmission disc 9, a hydraulic cylinder 10, an oil distributor 11, and a ditching cutter head 12. Gear box 13, frame pole 15, clutch assembly 16, clutch pull wire 17, oil pipe 18 and frame 21, the bottom end of frame pole 15 is fixed on the rear end of frame 21, and the bottom end of frame pole 15 The top is fixed on the hydraulic rod of the hydraulic cylinder 10, the oil distributor 11 is connected to the hydraulic cylinder 10 through the oil pipe 18, the gearbox 13, the gearbox disc 9 and the ditching cutter head 12 are installed on the frame 21, the output shaft of the gearbox 13 The transmission disc 9 is connected to the top, and the output shaft of the transmission disc 9 is connected with the ditching cutter head 12, and the front end of the frame 21 is installed with the frame transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com