Machining method of corrosion-resisting shaft and corrosion-resisting shaft

A processing method and anti-corrosion technology, applied to shafts and bearings, shafts, mechanical equipment, etc., can solve problems such as high cost and high price, and achieve the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

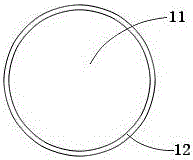

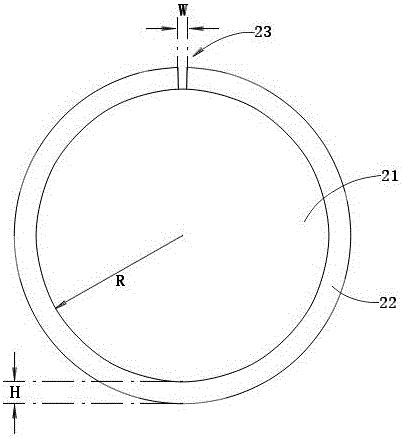

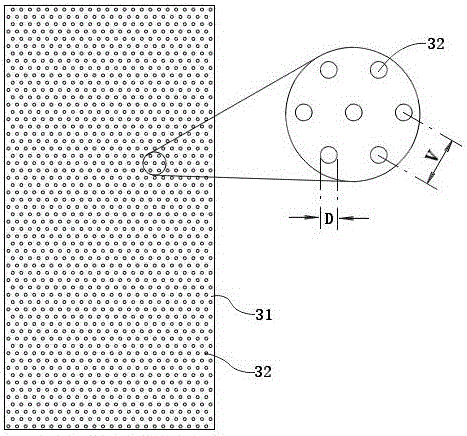

[0022] This embodiment relates to a corrosion-resistant shaft, such as figure 1 As shown, it consists of a shaft core 11 and a corrosion-resistant skin 12 wrapped on the shaft core 11 . Wherein, the shaft core 11 is processed into a columnar body from cast iron. The corrosion-resistant skin layer 12 is made of corrosion-resistant metal or alloy material, such as stainless steel, titanium alloy and the like. The specific material used for the corrosion-resistant skin layer 12 depends on the application scenario of the corrosion-resistant shaft. The thickness of the corrosion-resistant skin layer 12 is very thin, no more than 0.5 mm, generally 0.1-0.2 mm. The corrosion-resistant skin layer 12 is welded on the cylindrical surface of the shaft core 11 by means of laser spot welding, so that the shaft body processed by ordinary cast iron also has properties suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com