Tunnel facade film pasting device facilitating waste recovery

A film sticking device and a technology for recycling waste, applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of inability to ensure that the waterproof membrane is closely fitted with the outer facade of the tunnel, and the waterproof membrane cannot be attached to the outer facade of the tunnel, etc. To achieve the effect of saving resources, avoiding potential safety hazards, and avoiding wasting resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

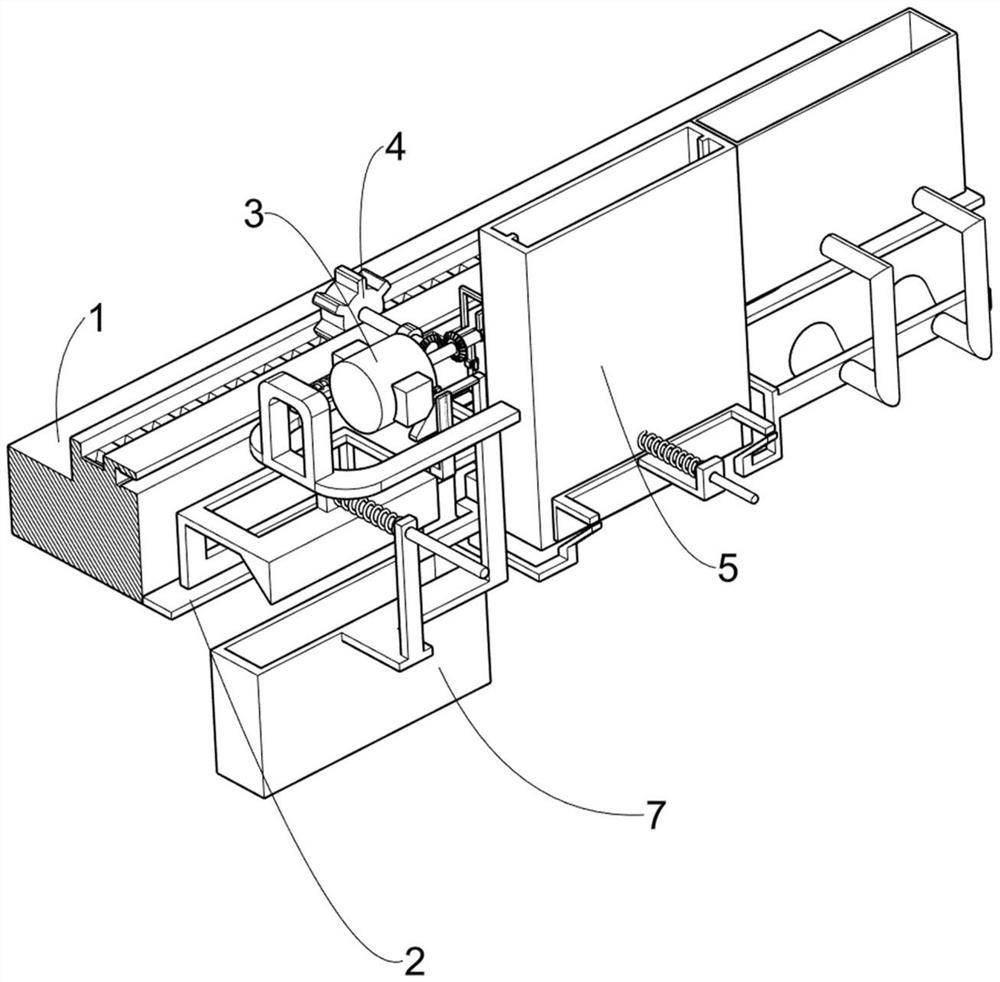

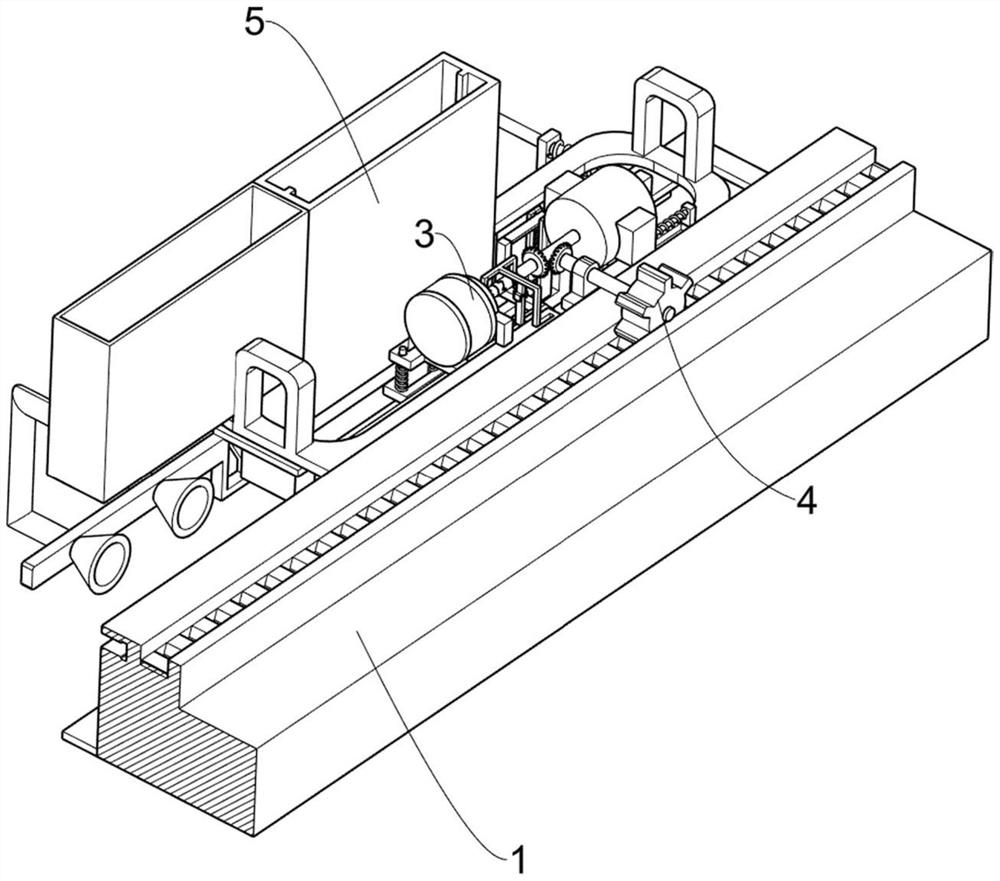

[0035] A tunnel façade film sticking device that is convenient for recycling waste, such as Figure 1-17 As shown, it includes a slide rail 1, a magnet plate 2, a lifting mechanism 3, a moving mechanism 4, a feeding mechanism 5 and a reset mechanism 6. The top of the slide rail 1 is provided with a toothed chute. Under the action of the slide rail 1, the flat The gear 42 and its upper device will move a certain distance, the slide rail 1 is connected with the magnet plate 2, the lifting mechanism 3 is set on the slide rail 1, and the lifting mechanism 3 is used to closely fit the waterproof membrane 312 on the tunnel facade On one side, the moving mechanism 4 is located on the lifting mechanism 3 , the unloading mechanism 5 is located on the lifting mechanism 3 , the unloading mechanism 5 is used for automatic unloading, and the reset mechanism 6 is located on the lifting mechanism 3 .

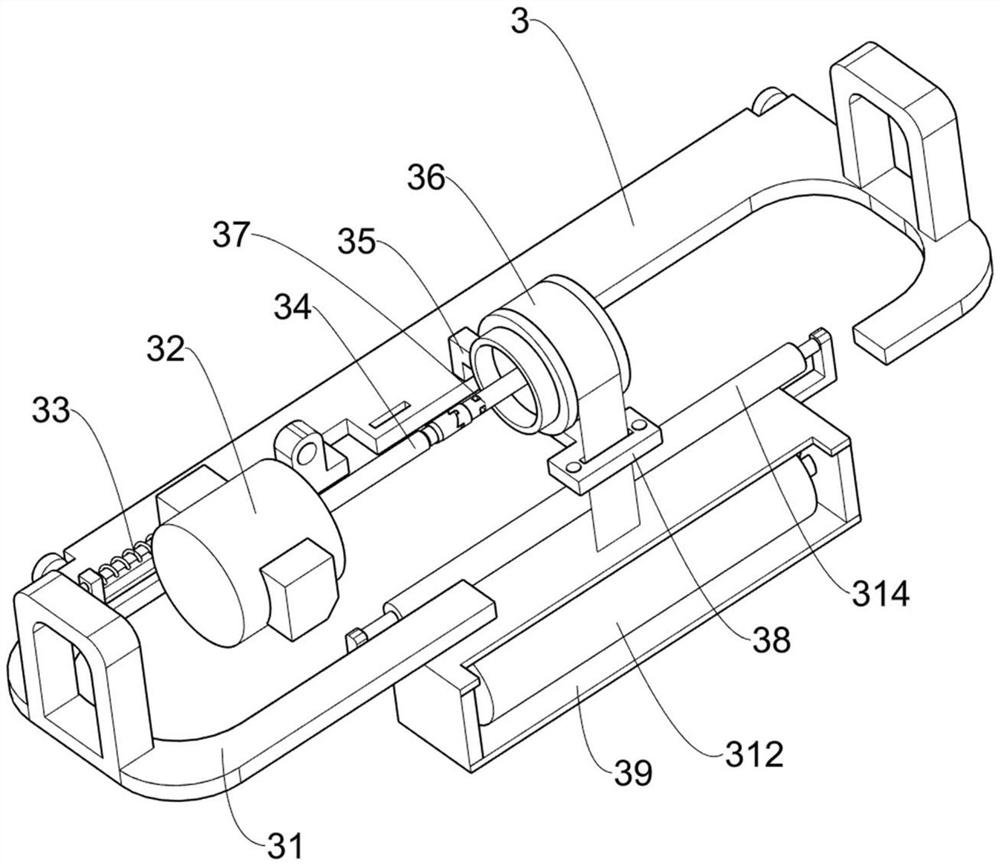

[0036]The lifting mechanism 3 includes a first sliding frame 31, a motor 32, a first retur...

Embodiment 2

[0047] On the basis of Example 1, such as Figure 15-17 As shown, a collection mechanism 7 is also included, and the collection mechanism 7 is arranged on the first sliding frame 31. The collection mechanism 7 is used to collect the rollers that have used up the waterproof membrane 312. The collection mechanism 7 includes a collection frame 71, a first wedge frame 72, the second fixed rod 73, the second wedge frame 74 and the sixth return spring 75, the collection frame 71 is connected to the bottom of the first sliding frame 31, the first wedge frame 72 is connected to the third fixed frame 55, the first wedge frame 72 is used to push the second wedge frame 74 and its upper device to move away from the slide rail 1, the second fixed rod 73 is slidably connected to the collection frame 71, and the second fixed rod 73 is fixedly connected with the second wedge frame 74 , the second wedge frame 74 is used to push the roller of the used waterproof membrane 312 to move to the coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com