Machine vision-based touchpad alignment system

A machine vision and touch panel technology, applied in the direction of assembling printed circuits with electrical components, can solve problems such as affecting the conductivity of capacitors, increasing the defective rate of touch panels, affecting assembly, etc., to ensure quality, ensure the conductivity of capacitors, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

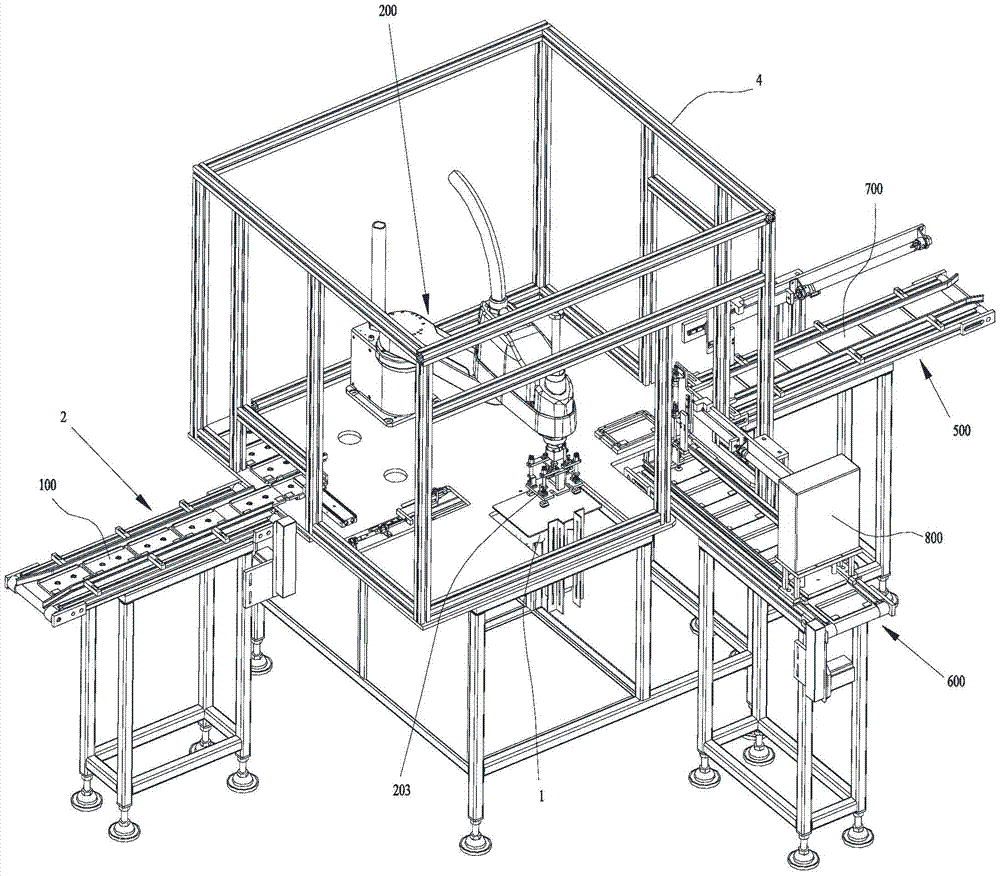

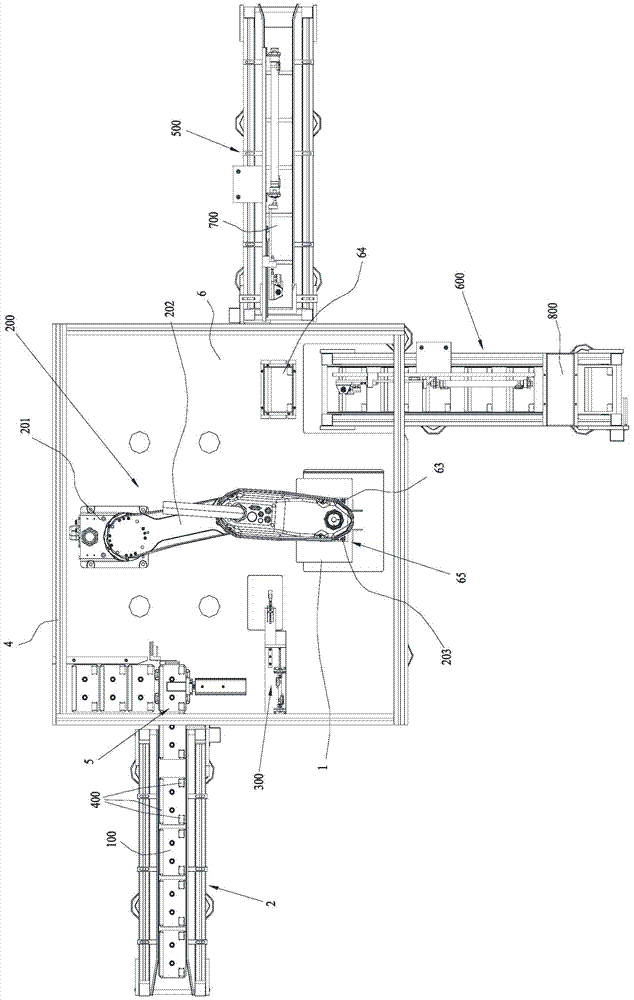

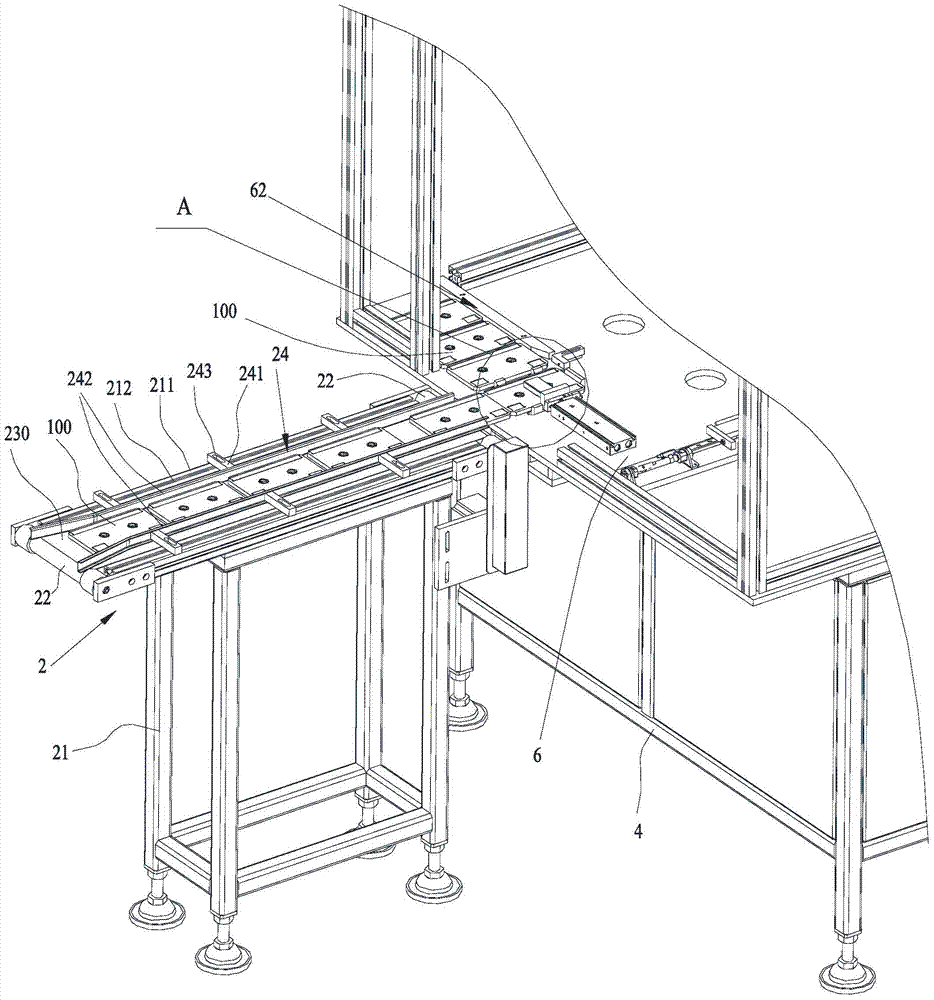

[0033] Such as Figure 1~2 The shown touchpad alignment system based on machine vision includes a frame 4, a platform 6 provided with a position to be grasped 5, a fitting position 64 and a calibration position 65 for inputting and positioning the aluminum sheet 400 on the position to be grasped. The conveying and positioning device for the grasping position 5, the input mechanism 500 for conveying into the touch panel 700, the output mechanism 600 for outputting pasted products, the manipulator 200 for grasping the aluminum sheet 400 and the calibration of the manipulator 200 for calibrating Alignment mechanism, the platform 6 is horizontally supported on the frame 4, the conveying positioning device, the input mechanism 500 and the output mechanism 600 all protrude from the inside of the frame 4, and the conveying outlet of the conveying positioning device is directly opposite to the position to be grasped 5 , the conveying outlet of the input mechanism 500 and the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com