Tire port ring automatic rubber removing machine for preparing high-performance steel shots

A high-performance, tire technology, applied in recycling technology, plastic recycling, etc., can solve the problems of uneven knife edge, uncertain extrusion position, high labor intensity, etc., and achieve the effect of uniform rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

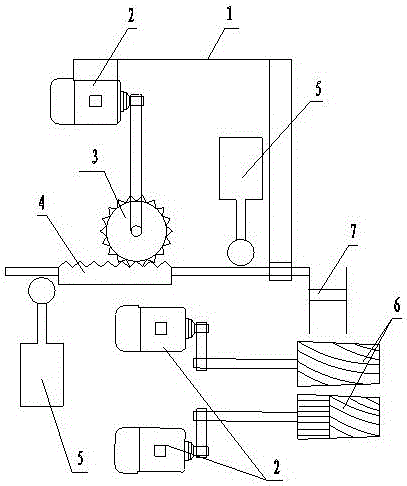

[0015] in such as figure 1 In the shown embodiment, an automatic degumming machine for preparing high-performance steel shot tire rims consists of a frame 1, a speed regulating motor 2, a gear 3, a rack 4, a proximity switch 5, a squeeze roller 6, a push-pull The feeder 7 and the controller are composed of a speed-regulating motor 2 on the frame 1, and the speed-regulating motor 2 transmits power to the extrusion roller 6 through a belt. The extrusion rollers 6 are arranged in pairs, rotate in opposite directions, and are located on the same On the horizontal plane, it is in the shape of a truncated cone, and the surface of one extrusion roller 6 is provided with inclined uneven grooves, the cylindrical surface of the other extrusion roller 6 is provided with linear grooves, and the surface of the conical table is provided with inclined uneven grooves. For uneven grooves, the extrusion roller 6 is divided into two parts, one part is cylindrical and the other is truncated cone....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com