Air inlet structure of plastic wine barrel

A technology of air intake structure and wine barrel, which is applied in the direction of closing, packaging, transportation and packaging, etc. It can solve the problems of lack of guiding structure, easy tilt, eccentricity of the wine outlet pipe, and influence on the stability of wine outlet, so as to achieve smooth movement, Good wine-making effect and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

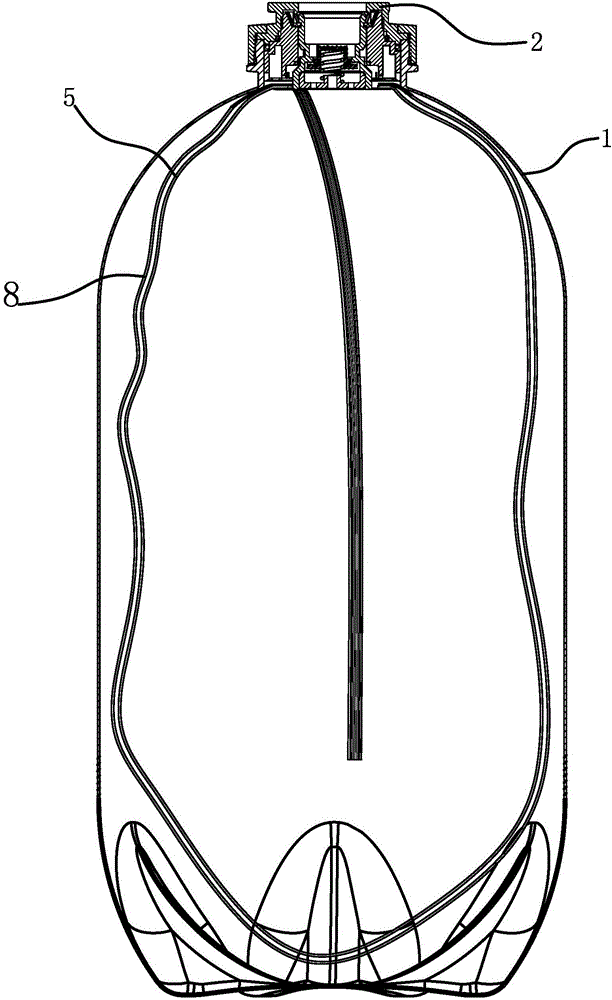

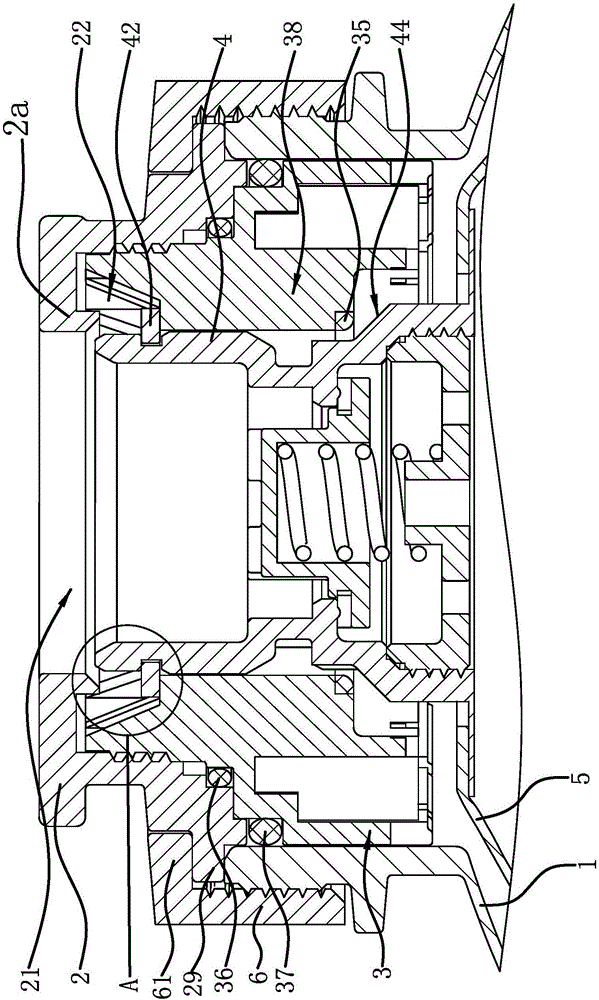

[0050] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the air intake structure of a plastic wine barrel, the plastic wine barrel includes a barrel body 1, a wine spearhead 2, a guide sleeve 3 and a positioning sleeve are fixedly connected to the mouth of the barrel body 1, and the guide sleeve 3 is inserted into the barrel body 1, the wine spear head 2 is set on the upper end of the guide sleeve 3, and the inner wall of the wine spear head 2 and the outer wall of the upper end of the guide sleeve 3 are fixedly connected by thread fit. The mouth of the barrel body 1 is provided with a positioning sleeve 6, the inner wall of the positioning sleeve 6 is fixedly connected with the outer wall of the barrel mouth of the barrel body 1 through thread fit, and there is a pressing convex edge 61 on the inner edge of the upper port of the positioning sleeve 6. The pressing convex edge 61 presses against the connecting convex edge 29 of the wine spear 2, and the connecting ...

Embodiment 2

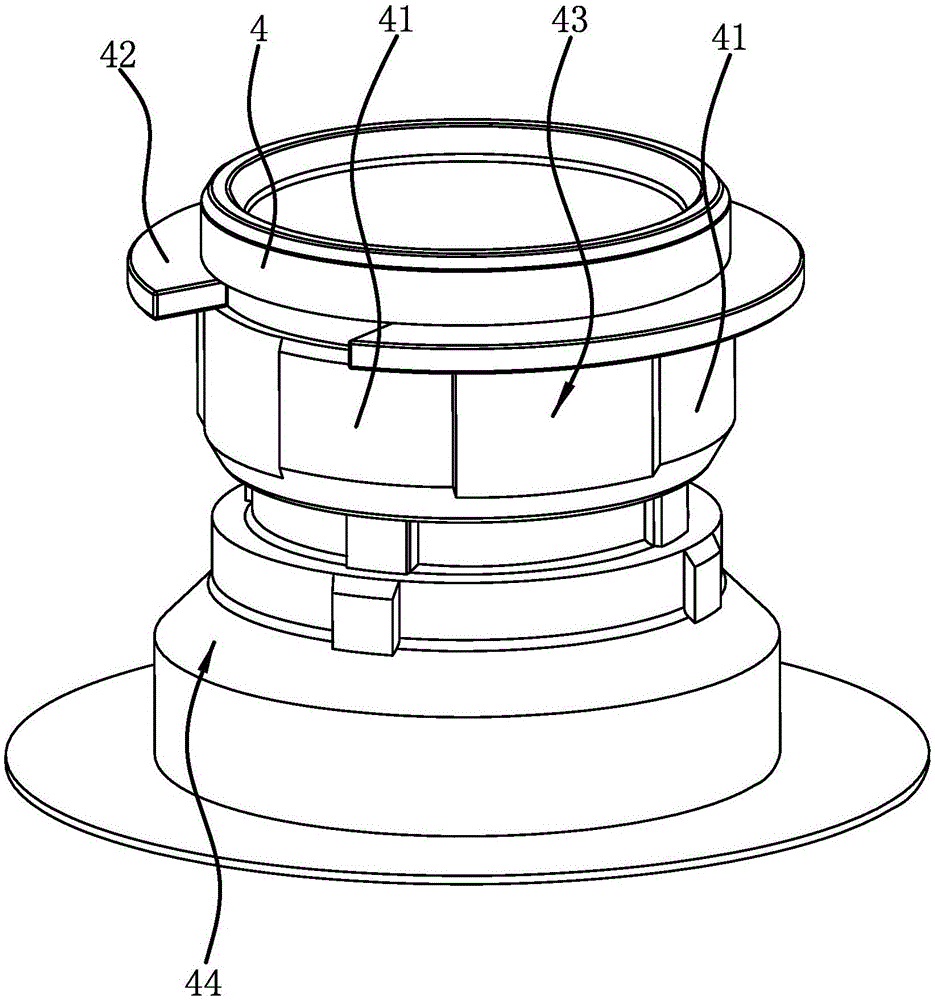

[0056] The air intake structure of the plastic wine barrel is basically the same as that of Embodiment 1, the differences are as Figure 8 ~ Figure 12 As shown, the lower end of the wine spearhead 2 has a cylindrical fastening portion 24, the inner wall of the fastening portion 24 has a connecting groove 25, and the outer wall of the barrel mouth of the barrel body 1 has a locking protrusion 11, and the fastening portion 24 is sleeved on the barrel. On the edge of the mouth of the barrel body 1, and the buckle joint 24 and the edge of the barrel mouth of the barrel body 1 are fastened and fixedly connected through the cooperation of the card protrusion 11 and the connecting groove 25. The guide sleeve 3 includes an inner sleeve body 31 and an outer sleeve body 33. The body 33 is located outside the inner sleeve body 31, and there are several partitions 38 in the circumferential direction between the outer sleeve body 33 and the inner sleeve body 31. The upper end edge of the ou...

Embodiment 3

[0058] The air intake structure of the plastic wine barrel is basically the same as that of Embodiment 2, the differences are as follows: Figure 13 As shown, the top of the wine spear head 2 has a radially inwardly extending edge portion 2a, an air intake cavity 22 is formed between the edge portion 2a and the upper end of the guide sleeve 3, and the upper end of the air intake passage 43 is connected to the upper end of the air intake channel. Cavities 22 communicate with each other, and the upper end port of joint 4 is opposite to the center hole 21 of wine spearhead 2. On the side wall of joint 4, there are also several inner holes connecting joint 4 and air inlet 23 of air intake chamber 22 in the circumferential direction, and joint 4 The upper end of the guide sleeve 3 is higher than the guide sleeve 3, so that the air inlet 23 is connected with the air inlet chamber 22, and the gas in the center hole 21 of the wine spear head 2 needs to enter the joint 4 and then enter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com