An engine air compressor resonant cavity

A resonant cavity and air compressor technology, which is applied in the resonant cavity of the engine air compressor to improve the oil leakage and intake noise of the engine air compressor, can solve the problems of large space occupation and limited noise reduction ability, and increase the sound wave reflection Effects of harmonizing sound energy loss, reducing discharge speed, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

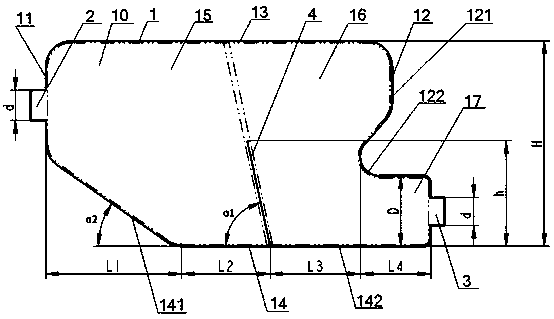

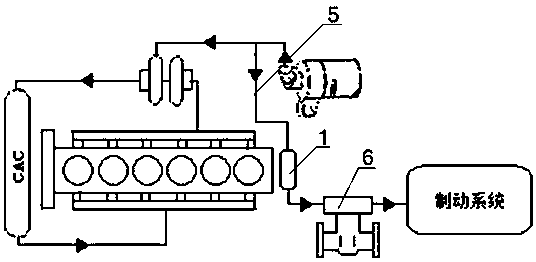

[0036] see figure 1 , figure 2, a resonant cavity of an engine air compressor, the resonant cavity 1 is a box structure, and its volume is at least 5 times the displacement of the air compressor 6, and the air intake side 11 of the resonant cavity 1 is provided with a The air inlet 2 communicated with the air intake pipe 5 of the compressor, the exhaust side 12 of the resonant cavity 1 is provided with the exhaust port 3 communicated with the air intake of the air compressor 6, and the air inlet 2 is close to the top surface of the resonant cavity 1 13, the exhaust port 3 is set near the bottom surface 14 of the resonant cavity 1, and the interior of the resonant cavity 1 is provided with a partition 4, which divides the inner cavity 10 of the resonant cavity 1 into an air intake cavity 15, an exhaust gas Cavity 16, the bottom end of partition plate 4 is fixedly connected with bottom surface 14, there is a gap between the top end of partition plate 4 and top surface 13, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com