Flexible air damper assembly for air conditioner and air conditioner

A windshield and air conditioner technology, which is applied in air conditioning systems, space heating and ventilation, applications, etc., can solve the problems of reducing the size and disadvantages of air conditioners, and achieve the effect of reducing the size and occupying the space of the air duct

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

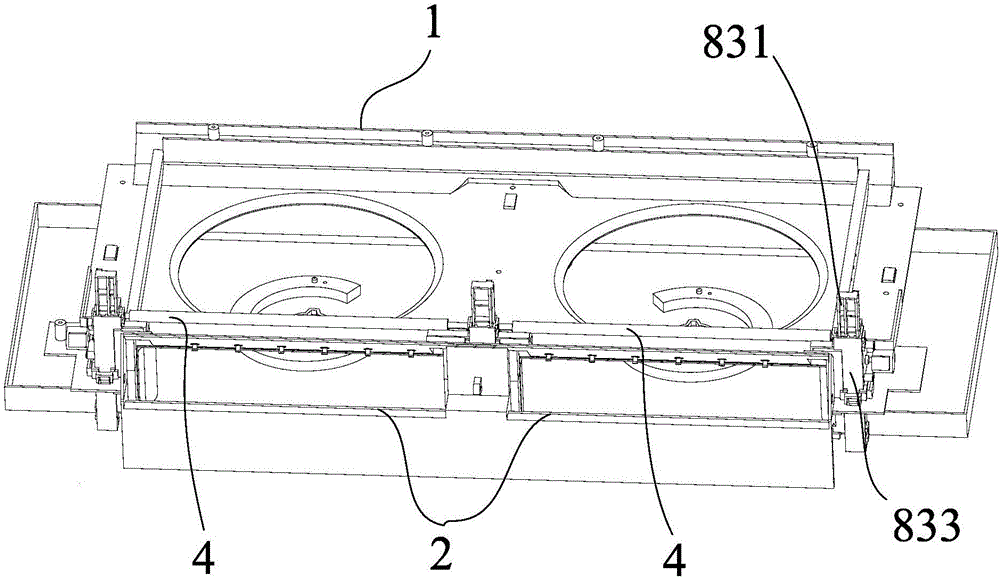

[0030] In this embodiment, a driving part is used to simultaneously drive the rotating shaft 4 to roll up and lower the flexible wind deflector 3 and the support part 31 through a transmission assembly to drive the movement of the lower edge of the flexible wind deflector 3, specifically, as Picture 9 As shown, the drive assembly 8 includes a drive 81, a first drive assembly 82, and a second drive assembly 83. The drive 81 is drivingly connected to the shaft 4 through the first drive assembly 82, and the drive 81 is connected to the support through the second drive assembly 83. 31 is in transmission connection, the first transmission component 82 and the second transmission component 83 can make the support 31 move synchronously with the lower edge of the flexible wind deflector 3. Since only one driving member 81 is provided, the driving member 81 drives the shaft 4 through the first transmission assembly 82 and the second transmission assembly 83 to roll down the flexible wind...

Embodiment 2

[0041] The difference between this embodiment and the first embodiment is that in this embodiment, two driving parts drive the rotating shaft 4 to roll up and lower the flexible wind deflector 3 through a transmission assembly, and the support part 31 drives the movement of the lower edge of the flexible wind deflector 3. Specifically, the driving assembly 8 includes a first driving member and a second driving member. The first driving member is used to drive the rotating shaft 4 to rotate, and the second driving member is used to drive the support member 31 to follow the downward direction of the flexible windshield 3 in the vertical direction. The edges move synchronously. Since the shaft 4 is driven to rotate by two driving parts and the supporting part 31 moves synchronously with the lower edge of the flexible windshield 3 in the vertical direction, the power requirement for each driving part is reduced, and two driving parts can be selected Lower power driver. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com