Automatic ammunition belt feeding device for bullets

An automatic technology of ammunition chain, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of high labor intensity, manual loading of the ammunition chain, vulnerable hands, etc., and achieve the effect of efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the automatic belt loading device for bullets of the present invention will be further described in detail.

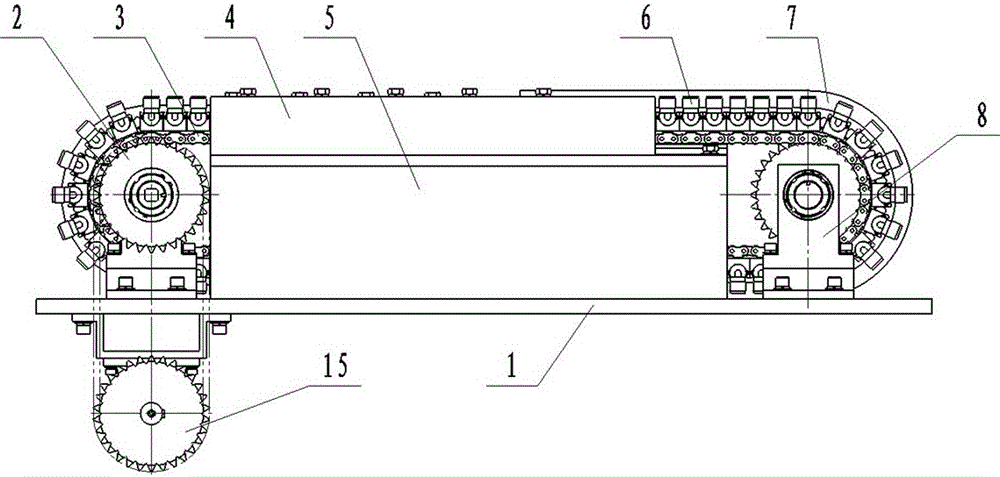

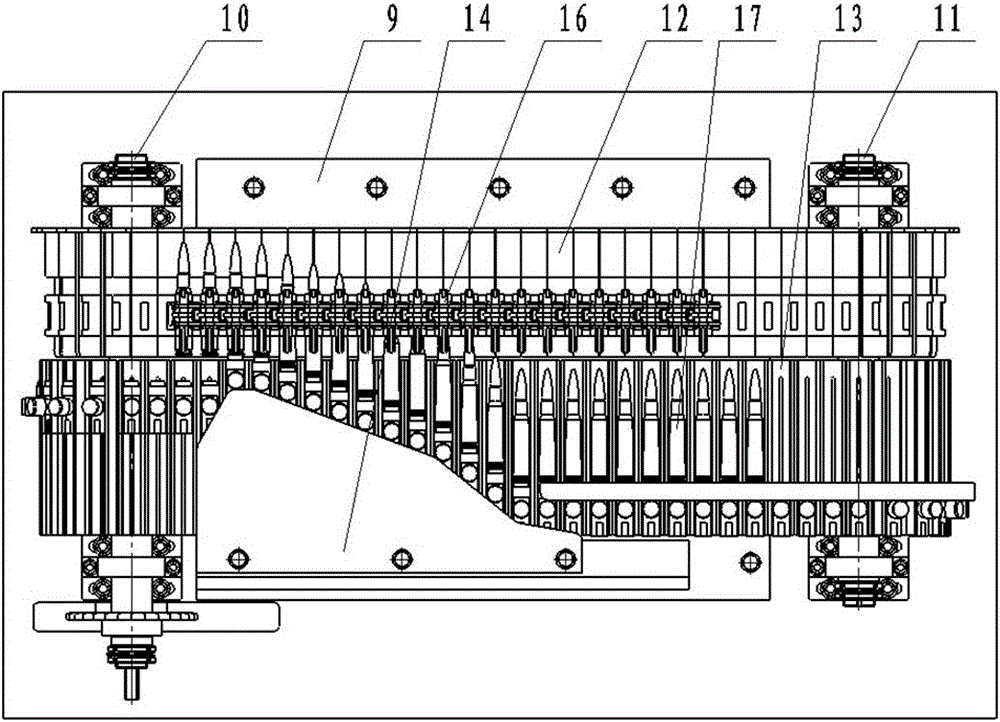

[0012] figure 1 It is the front view of the bullet automatic belt loading device of the present invention, figure 2 It is a top view of the automatic belt loading device for bullets of the present invention. like figure 1 , figure 2 As shown, the bullet chain loading device of the present invention includes: mounting plate 1, sprocket wheel 2, chain 3, cam mounting seat 4, channel steel 5, push rod 6, guide plate 7, bearing seat 8, support plate 9, Main transmission shaft 10, auxiliary transmission shaft 11, elastic chain template 12, elastic body template 13, plane cam 14, power unit 15, elastic chain 16, elastic body 17; Its connection relation is: this device is fixed on the worktable; The chain template 12 and the body template 13 are fixed on the chain 3; the sprocket 2 is fixed on the main transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com