Heavy rail clamping device

A technology of clamping device and heavy rail, which is applied in the field of limit centering device for heavy rail, which can solve the problems of difficult detection equipment and wrong detection results, and achieve strong rail delivery ability, high control precision and stable operation of heavy rail Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

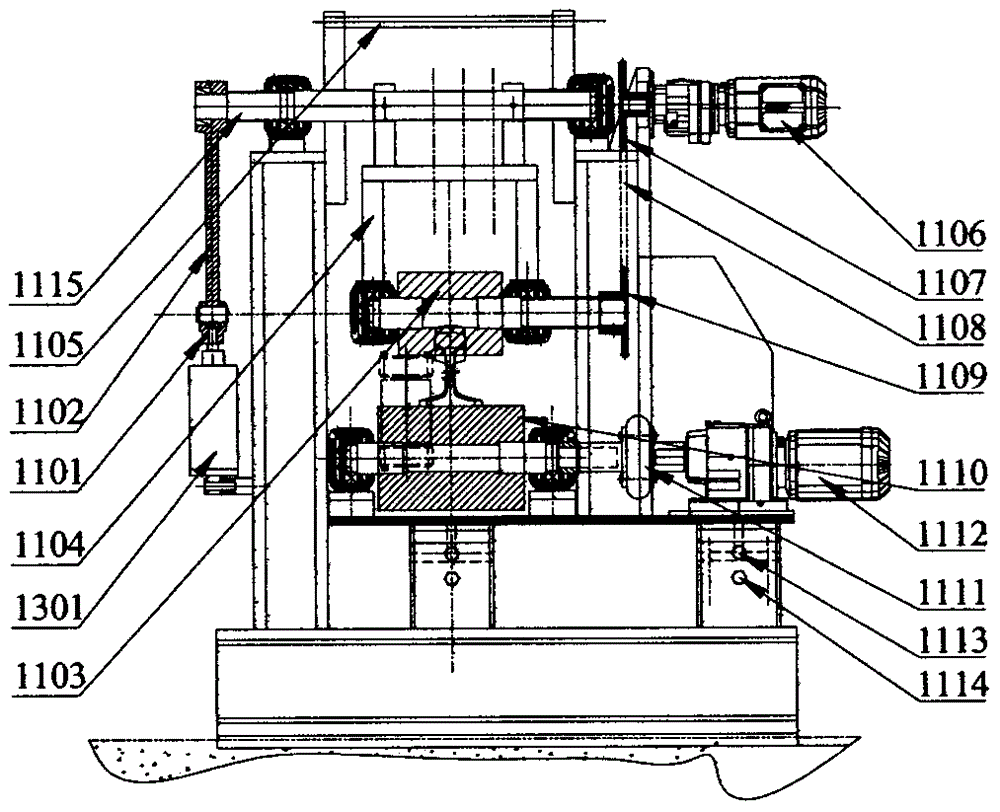

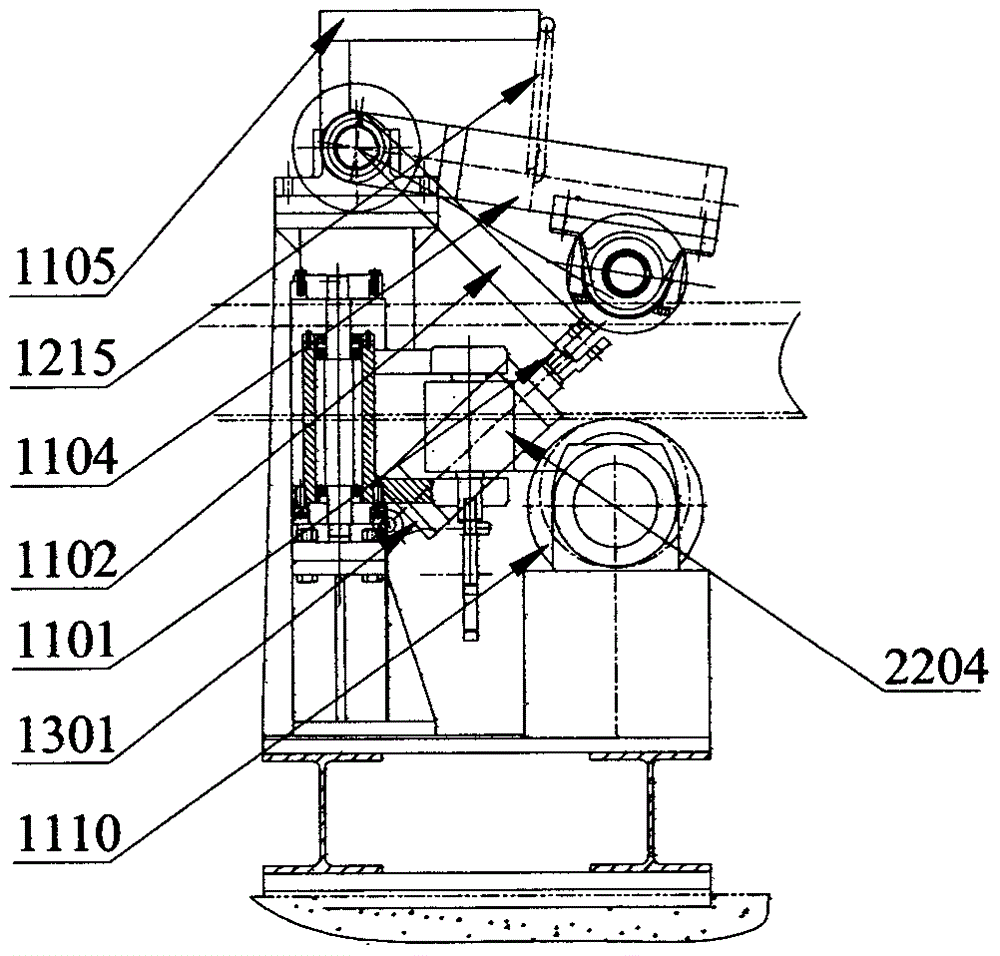

[0032] A heavy rail clamping device. The heavy rail clamping device such as figure 1 and figure 2 As shown: It consists of four parts: the upper and lower limit mechanism of the heavy rail, the left and right limit mechanism of the heavy rail, the pneumatic system and the frame.

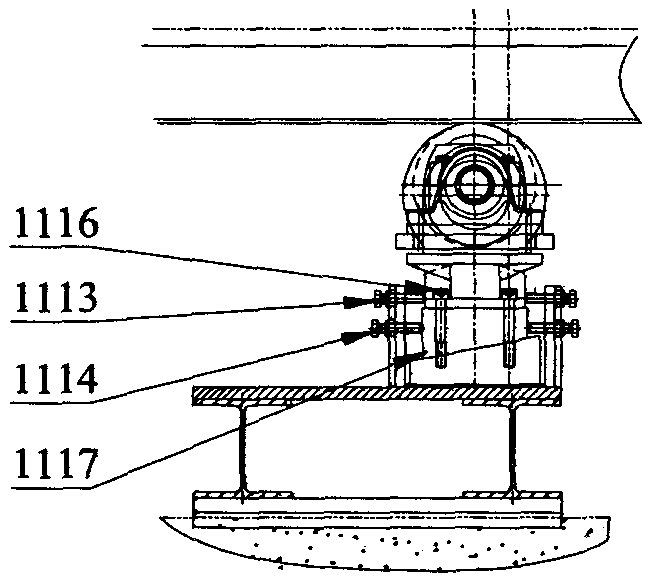

[0033] Such as figure 1 , figure 2 and image 3 As shown, the heavy rail upper and lower limit mechanism includes a rocker mechanism, a pressing roller protection device, a drive system, and a horizontal elevation adjustment device. The rocker mechanism includes a depressing cylinder piston rod 1101, a connecting rod 1102, and an output end frame 1104; the depressing roller protection device includes a fixed bracket 1105 and a rotating shaft 1115; the drive system includes a first drive Motor 1106, second driving motor 1112, shaft coupling 1111, first sprocket 1107, second sprocket 1109, chain 1108, pressing roller 1103, support roller 1110; Described horizontal elevation adjustment device com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com