Modeling and verifying method of laser gyroscope temperature compensation model

A laser gyroscope and temperature compensation technology, which is applied to Sagnac effect gyroscopes, instruments, measuring devices, etc., can solve the problems of inability to meet the requirements of inertial navigation equipment and the reduction of the accuracy of laser gyroscopes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following describes the embodiments of the present invention in further detail with reference to the accompanying drawings:

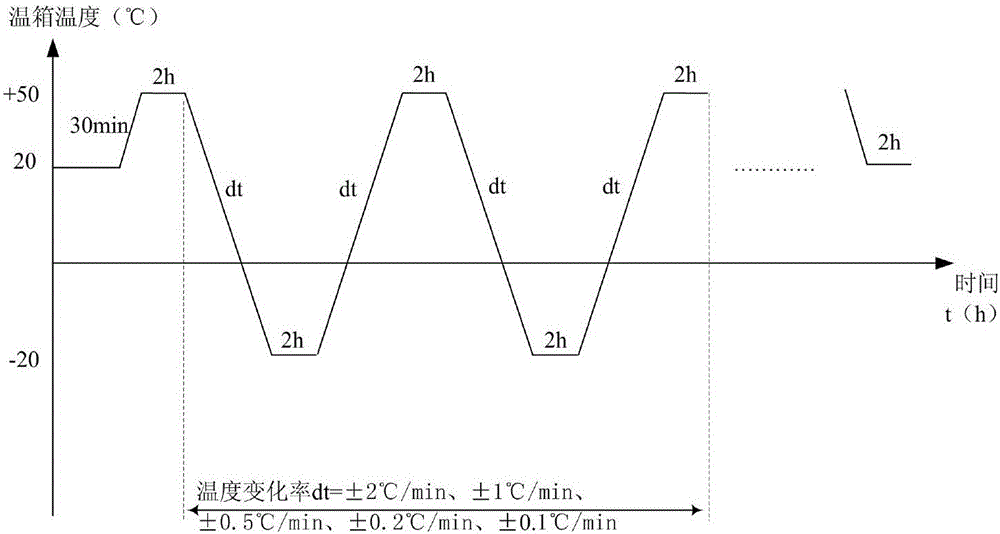

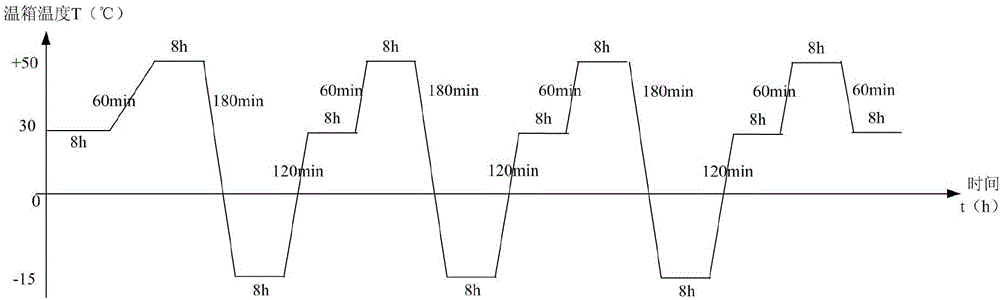

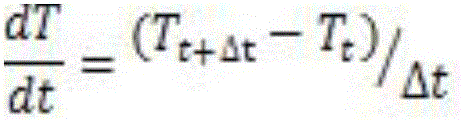

[0047] The present invention firstly generates a temperature cycle in the range of -20°C to +50°C through the temperature test box during the modeling test of the temperature compensation model of the laser gyroscope to obtain the coefficient of the temperature term in the temperature compensation model; then the temperature test box is used The internal temperature changes are circulated at the speeds of ±2℃ / min, ±1℃ / min, ±0.5℃ / min, ±0.2℃ / min, ±0.1℃ / min, and get the temperature compensation model related to the temperature change rate Coefficients and coefficients related to the coupling terms of temperature and temperature change rate; finally, a set of verification tests weakly related to the laser gyroscope temperature compensation model modeling test are established, from the dual indicators of laser gyroscope bias stability and bias repeata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com