Blower fan feature multipoint pressure synchronous measurement test system

A technology of synchronous measurement and test system, applied in the pressure difference measurement between multiple valves, transmission system, measurement device, etc., can solve the problems of low accuracy, low efficiency, large workload, etc., to improve the test accuracy and improve the test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

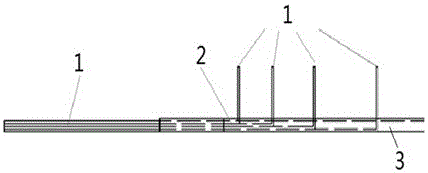

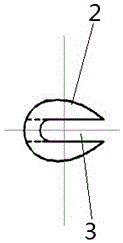

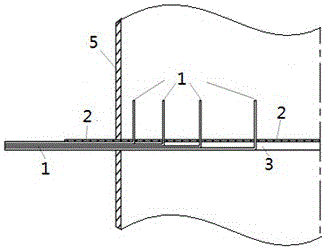

[0017] The fan characteristic multi-point pressure synchronous measurement and testing system includes a miniature total pressure tube 1, a support rod 2, and a test tube. There are grooves on the wall and holes on the other side of the pipe wall. The number of diameters, positions and the number of test points distributed on each diameter in the test cross-section on the test tube are determined according to the neutral linear method or the Chebechev method , position, the number and position of the support rods 2 in the pipeline test cross-section are the same as the number and position of the diameter, the number and position of the holes are the same as the number and position of the test points on each diameter The same, the number of the miniature full-pressure tube 1 is the same as the number of the holes, one right-angled side of the miniature full-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com