A turbine test bench

A technology of experimental bench and turbine, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., can solve the problems of single fluid and non-interchangeability, achieve convenient operation, and shorten the cycle of research and development and design , design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

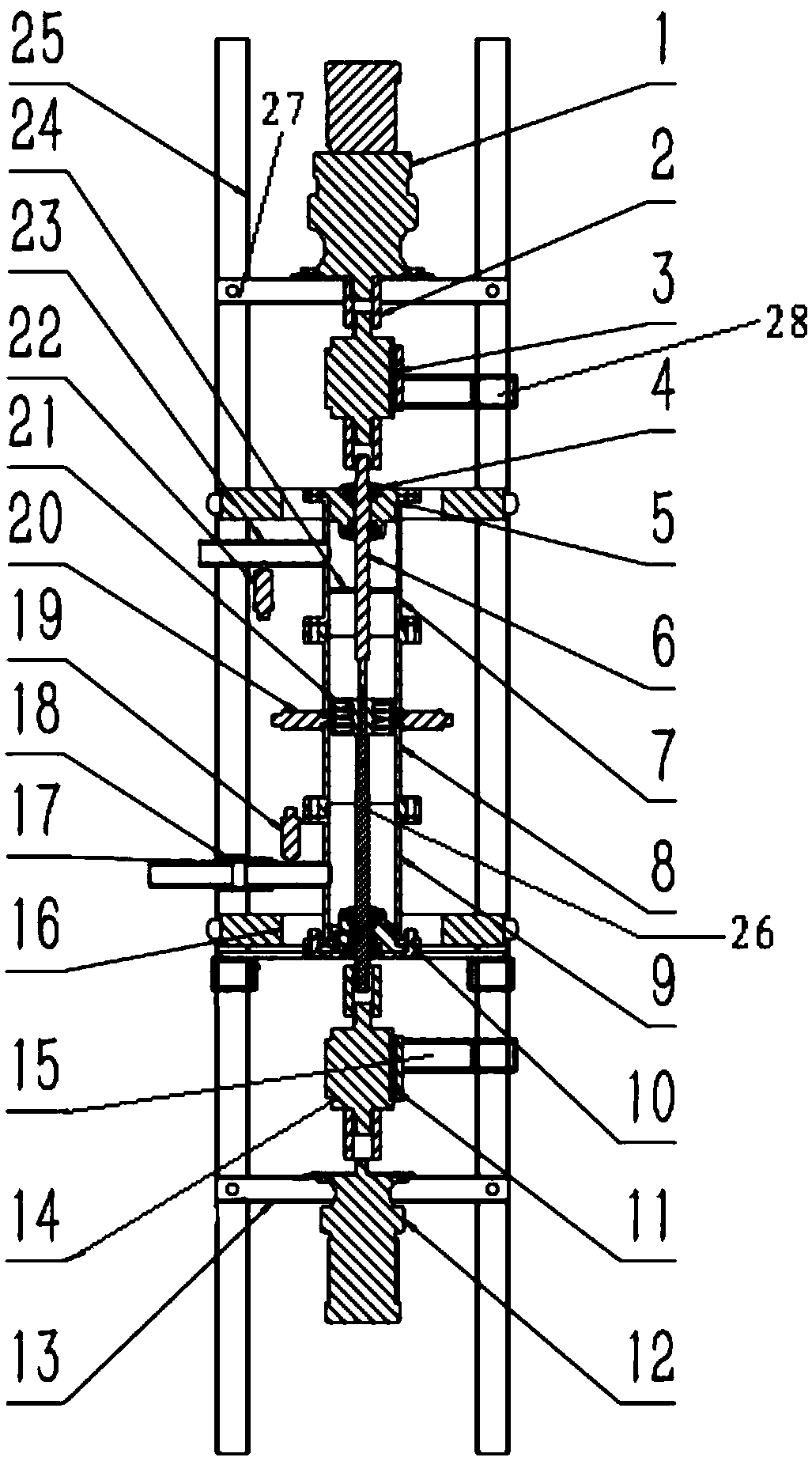

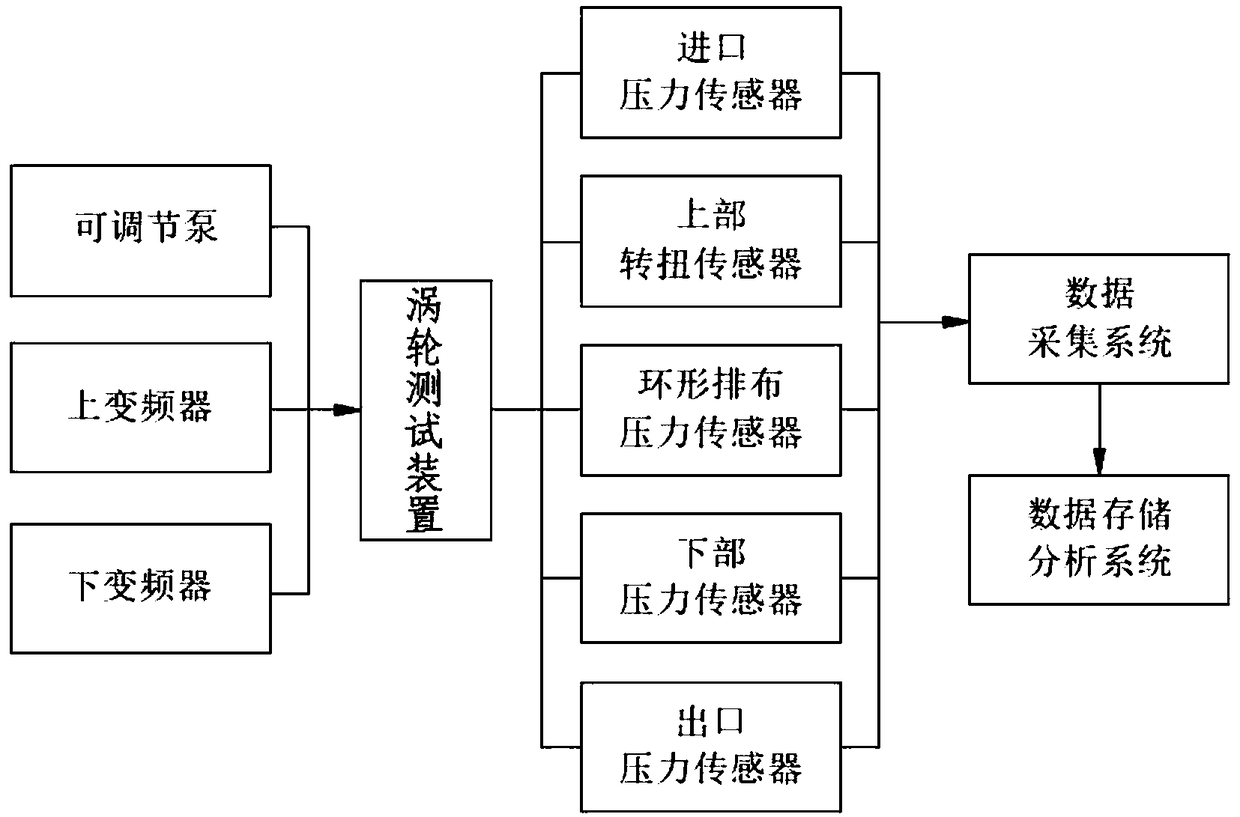

[0037] The performance of a single turbine under different flow fields: select a suitable fluid pump as the fluid source, keep the upper motor 1 in a non-working state, use the lower motor 12 as the load motor, install a single turbine on the lower turbine installation shaft 26, and select different pump pressures , pump flow, and sensors with a specified range can test the performance of a single turbine in the flow field. This test mode is suitable for testing the performance of turbine components such as downhole power generation turbines for measurement while drilling and supercharged turbines for automobile engines.

Embodiment 2

[0039] The performance of multi-stage turbines under different flow fields: Keep the upper motor 1 in a non-working state, the lower motor 12 is used as a load motor, install a multi-stage turbine on the lower turbine installation shaft 26, and select different experimental parameters and specified range sensors , which can measure the performance test of multi-stage turbine in fluid. This test mode is suitable for testing the performance of single-stage turbodrill stator and rotor and multi-stage turbine stator and rotor. In fact, the performance of the multi-stage turbine stator and rotor is not a simple superposition of the performance of the single-stage turbine stator and rotor. There is mutual influence between the turbines of each stage, and its influence on the flow field is also different from that of the single-stage turbine. Using this turbine test bench can It is convenient to study the above effects.

Embodiment 3

[0041] Contra-rotating turbine: Both the upper motor 1 and the lower motor 12 are used as load motors. The two parts of the counter-rotating turbine are respectively installed on the upper turbine installation shaft 6 and the lower turbine installation shaft 26. Different fluid media and test parameters are selected to suitably match The range of sensors can test the hydrodynamic performance of the counter-rotating turbine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com