Automatically-controlled reciprocating load loading device for axial force-bearing component and using method thereof

A technology of loading device and force-bearing components, applied in the field of steel structure buildings, can solve the problems of component damage, lack of lateral support, and inability to test components, and achieve the effect of facilitating transportation and placement, and avoiding shear stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in further detail below in conjunction with accompanying drawing:

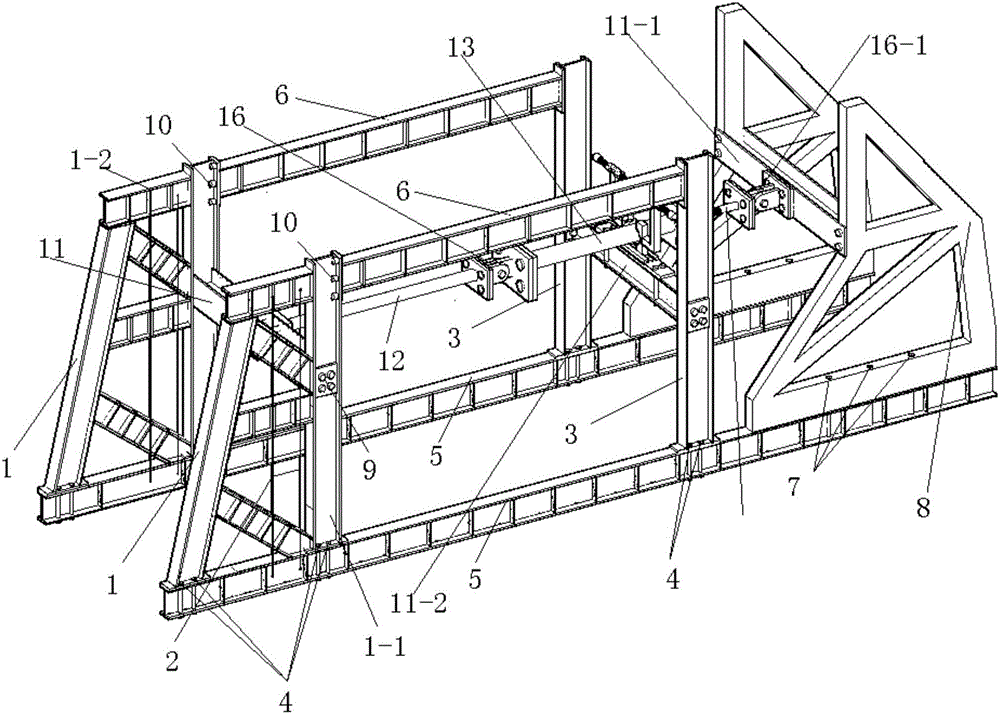

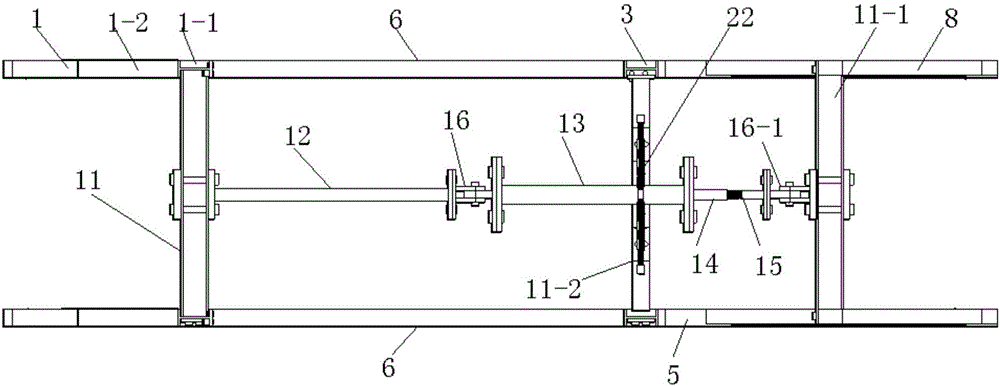

[0046] Such as Figure 1 to Figure 4 As shown, the reciprocating load loading device for automatically controlling the axial center force member of the present invention includes an external frame fixing device. The external frame fixing device is provided with a test piece loading device for loading the test piece 13. The test piece loading device is connected with data collection system;

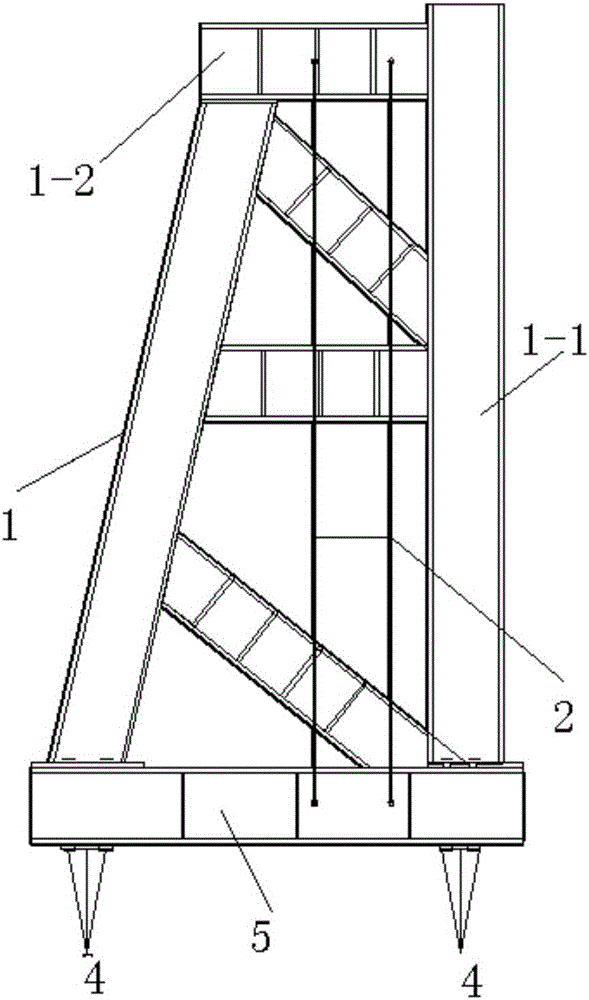

[0047] The external frame fixing device includes I-shaped steel beam caps 5 arranged side by side. The left and right sides of the I-shaped steel beam caps 5 are respectively connected with a trapezoidal horizontal reaction frame 1 and a triangular reaction frame 8 . The trapezoidal horizontal reaction frame 1 applies the prestressed prestressed steel cable 2, the upper end of the prestressed steel cable 2 is connected with the upper beam 1-2 of the trapezoidal horizontal reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com