Method for making artificial rock core by freezing drilling technology

An artificial core and drilling technology, applied in the preparation of test samples, etc., can solve the problems of failure to meet design requirements such as specific particle size composition, clay composition and content, high mining and transportation costs, and difficulty in obtaining permeability cores, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments are listed below and shown in the accompanying drawings in detail as follows.

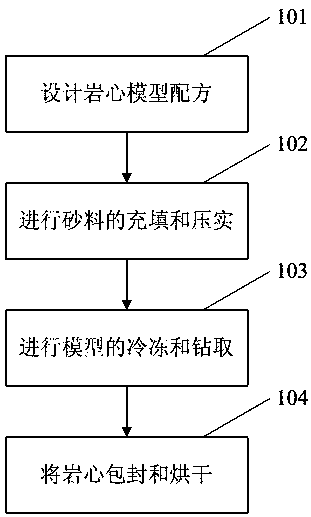

[0030] Such as figure 1 as shown, figure 1 It is a flow chart of the method for making artificial rock cores by utilizing freeze drilling technology of the present invention.

[0031] In step 101, a core model recipe is designed. In this step, according to the physical parameters of the target reservoir, such as particle size composition, clay composition and content, the ratio of quartz sand with different particle sizes to clay is determined, and wettability treatment is performed on the surface of the quartz sand according to the wettability characteristics of the reservoir.

[0032] In step 102, packing and compaction of sand material is performed. In this step, according to the amount of quartz sand and clay, an appropriate amount of water is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com