Composite high efficiency filter media with improved capacity

A filter medium and medium technology, applied in the field of high-efficiency and high-capacity filter media, can solve the problem of inability to obtain fine particle removal efficiency, pressure drop, etc., and achieve the effects of enhancing pollutant retention capacity, improving separation, and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

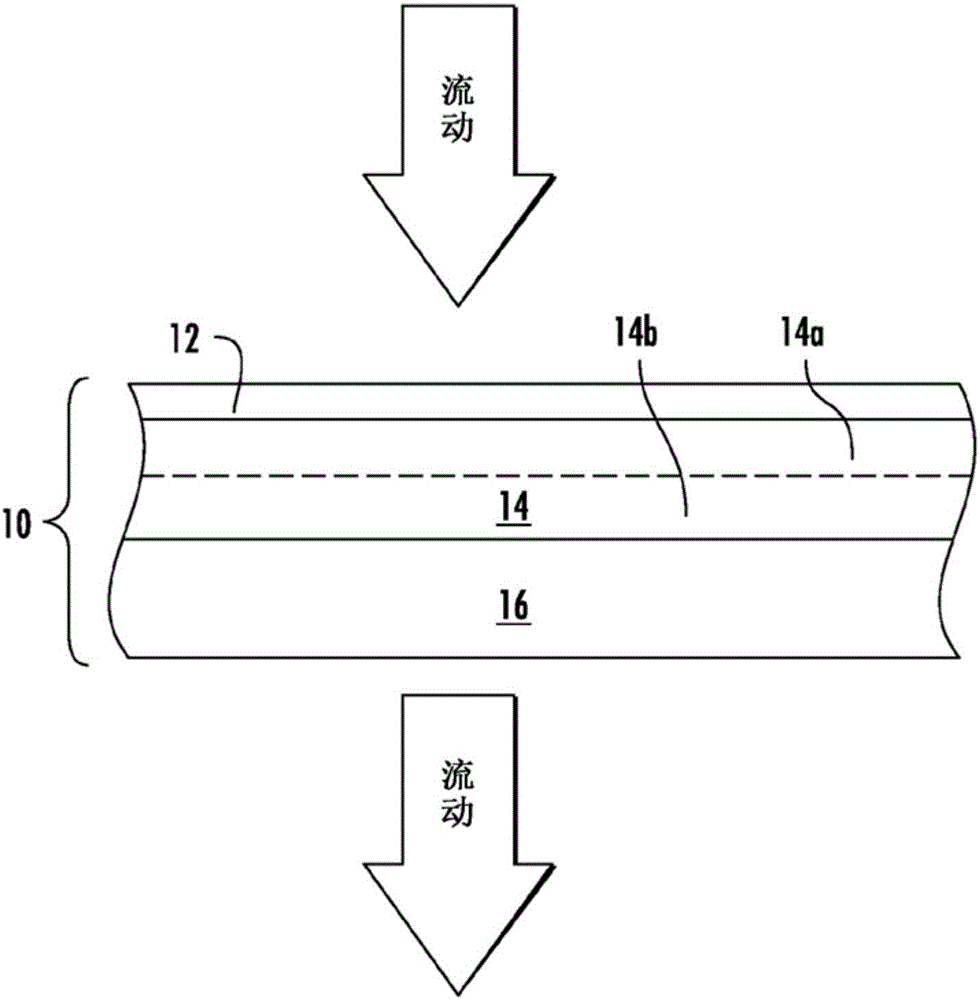

[0036] figure 1 is a cross-sectional view of the composite media 10 of the present disclosure showing (from the upstream face to the downstream face) optional lightweight protective cloth 12 , depth media 14 and base media 16 . Composite media 10 is intended for, but not limited to, the filtration of diesel fuel delivered to fuel injection systems of internal combustion diesel engines for on- and off-road vehicles and generator and marine applications. Fuel flows through the composite media from the upstream face at the optional protective cloth to the downstream face at the outlet side of the base media 16 . Depth media 14 and base media 16 will be discussed in terms of "upstream" and "downstream" sides, which relate to the direction of fuel flow through composite media 10 .

[0037] The composite media of the present disclosure can be used to make filter elements or cartridges for use in combination with fuel delivery systems. Figure 15 An exemplary cartridge 30 is shown....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com