Preparation method of atomizing core matrix and atomizing core

A technology of atomizing core and matrix, which is applied in the field of atomizing equipment, can solve problems such as difficulty in ensuring uniform heating, long sintering time, and slow heating rate, and achieve the effects of reducing burnt core phenomenon, shortening heating time, and increasing heating rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

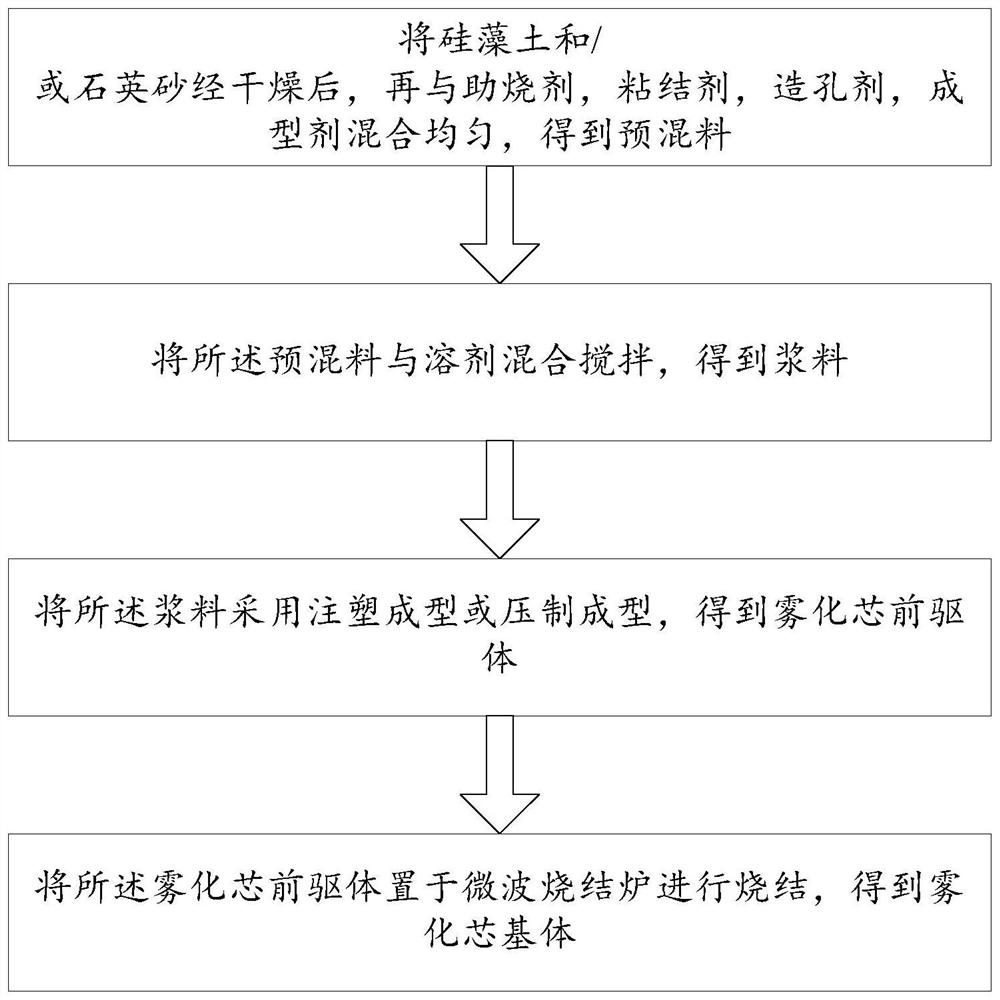

[0029] Such as figure 1 as shown, figure 1 It is a schematic flowchart of the preparation method of the atomizing core matrix in an embodiment of the present invention. The preparation method includes:

[0030] Dried diatomite and / or quartz sand, and then mixed with sintering aid, binder, pore-forming agent, and forming agent to obtain a premix;

[0031] mixing and stirring the premix with a solvent to obtain a slurry;

[0032] The slurry is molded by injection molding or pressing to obtain an atomizing core precursor;

[0033] The atomizing core precursor is placed in a microwave sintering furnace for sintering to obtain an atomizing core base.

[0034] The preparation method uses microwaves to couple with the basic microstructure of the atomizing core precursor to generate heat, and heats the atomizing core precursor as a whole through dielectric loss, and the low-loss heat preservation technology increases the heating rate, shortens the heating time, and reduces energy ...

Embodiment 2

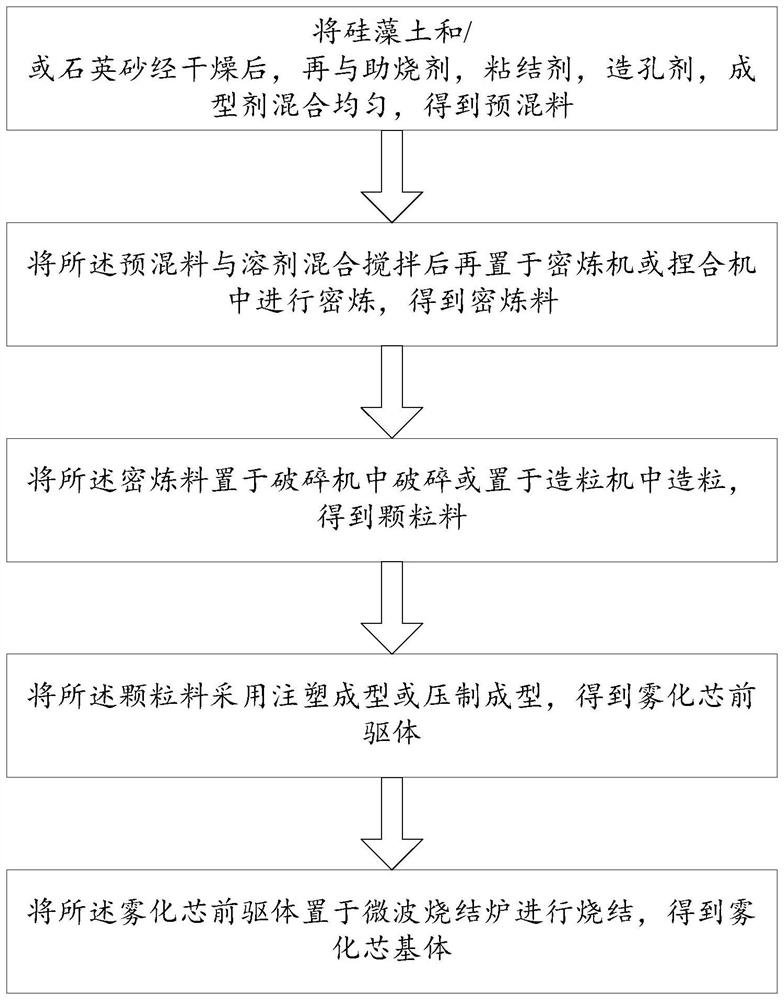

[0041] Such as figure 2 as shown, figure 2 It is a schematic flow chart of the preparation method of the atomizing core matrix in another embodiment of the present invention; the preparation method includes:

[0042] Dried diatomite and / or quartz sand, and then mixed with sintering aid, binder, pore-forming agent, and forming agent to obtain a premix;

[0043] mixing and stirring the premixed material with a solvent, and then placing it in a banbury mixer or a kneader for banburying to obtain a banbury;

[0044] placing the banburying material in a crusher for crushing or placing it in a granulator for granulation to obtain pellets;

[0045] The granules are molded by injection molding or pressing to obtain an atomizing core precursor;

[0046] The atomizing core precursor is placed in a microwave sintering furnace for sintering to obtain an atomizing core base.

[0047] The difference between this embodiment and Example 1 is that in this embodiment, the premix is mixe...

Embodiment 3

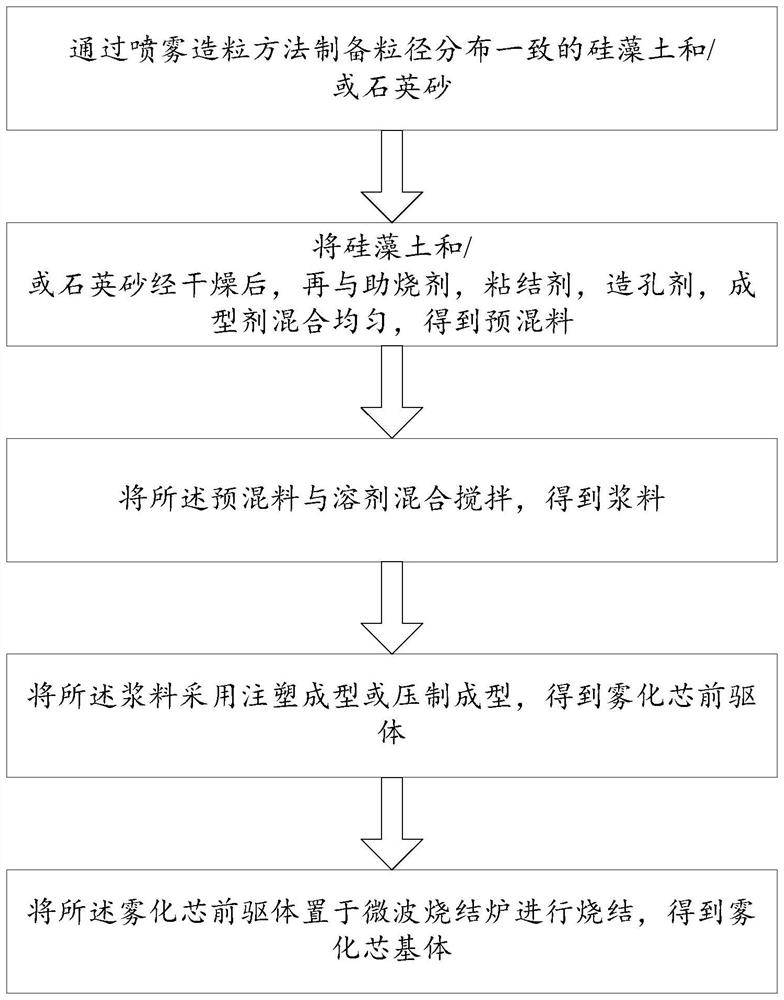

[0054] Such as image 3 as shown, image 3 It is a schematic flowchart of the preparation method of the atomizing core matrix in another embodiment of the present invention. The preparation method includes:

[0055] Prepare diatomite and / or quartz sand with uniform particle size distribution by spray granulation method;

[0056] Dried diatomite and / or quartz sand, and then mixed with sintering aid, binder, pore-forming agent, and forming agent to obtain a premix;

[0057] mixing and stirring the premix with a solvent to obtain a slurry;

[0058] The slurry is molded by injection molding or pressing to obtain an atomizing core precursor;

[0059] The atomizing core precursor is placed in a microwave sintering furnace for sintering to obtain an atomizing core base.

[0060]The difference between this example and Example 1 is that in this example, diatomite and / or quartz sand are dried, and then mixed evenly with sintering aid, binder, pore-forming agent, and forming agent. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com