Splicing bright/dark line adjustment method

An adjustment method and technology of bright and dark lines, applied in the field of display correction, can solve the problems of multiple sending times, cumbersome operation, and difficult undo, etc., achieve flexible operation, simplify adjustment steps, and solve the effects of temporary storage coefficient and long-term storage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

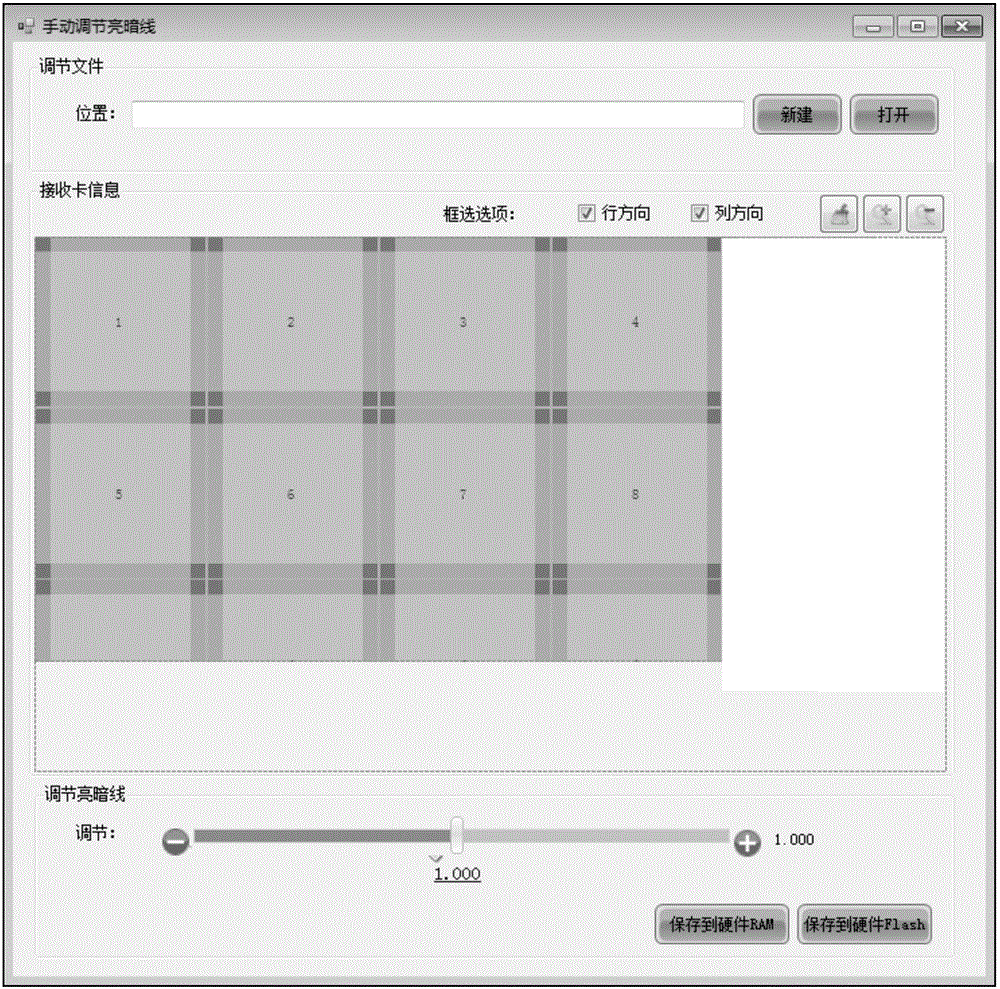

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The splicing bright and dark line adjustment method in the technical solution proposed by the following embodiments of the present invention saves the adjustment position and adjustment amount as a file in real time during the adjustment process, and sends the saved file to the LED display control at one time after all adjustments are completed. System hardware, at the same time, when sending the saved files to the LED display control system hardware, you can choose to send them to volatile memory (RAM) or non-volatile memory such as Flash (flash memory). If it is sent to RAM, the adjustment coefficient will be lost after the LED display control system hardware is powered off, which is suitable for LED screen rental occasions; if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com