Omnibearing subsoiler

A subsoiler, all-round technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve problems such as insufficient structural strength and lack of plant protection functions, to improve prevention and control work, improve economic and social benefits, and improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

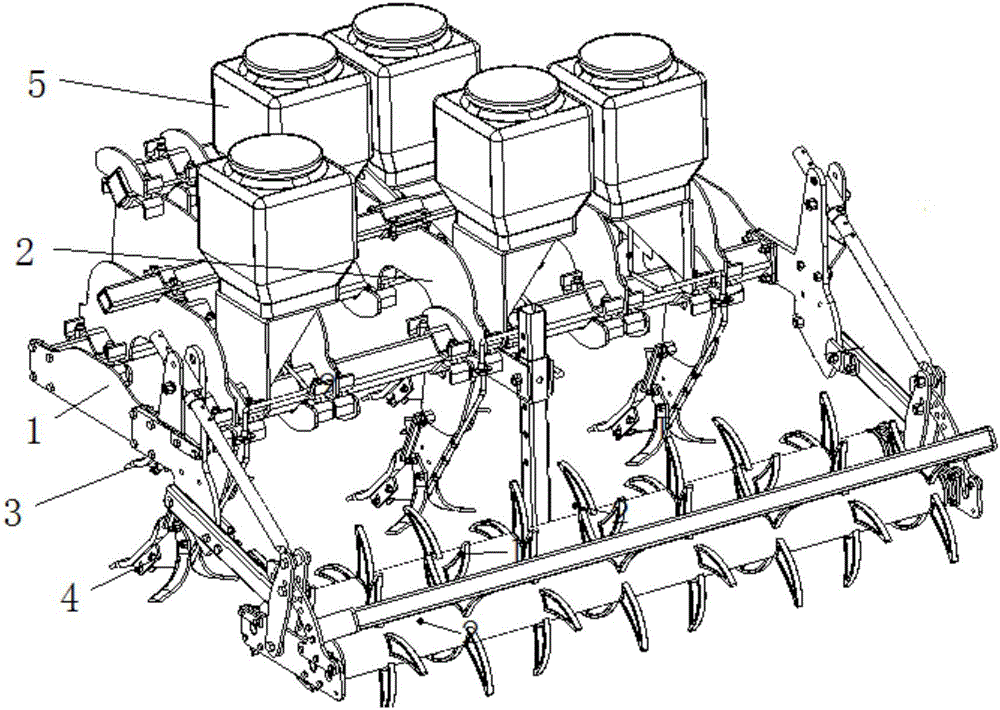

[0022] See attached picture:

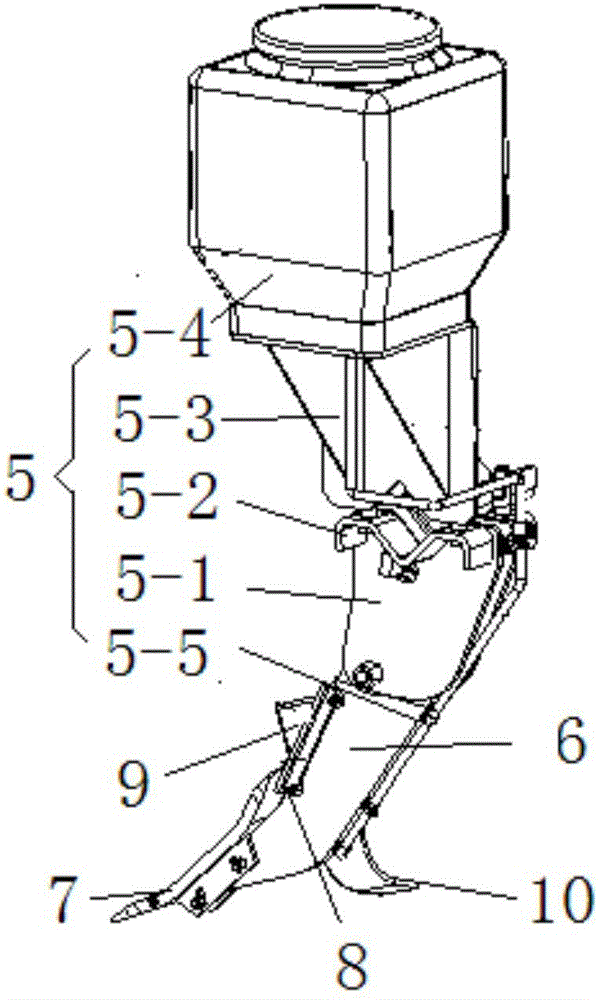

[0023] The omni-directional subsoiler includes a frame 1. The upper end of the frame 1 is equipped with a plurality of suspension plates 2 arranged at intervals. The suspension plate 2 is arched as a whole, and the front and rear subsoil pear tip assemblies are respectively installed at the front and rear ends of the suspension plate 2 3 and the rear plow tip sub-soiling assembly 4, the front row sub-pear tip assembly 3 and the rear plow tip assembly 4 are each equipped with a plant agent spraying device 5 at the upper end of each sub-plow tip assembly.

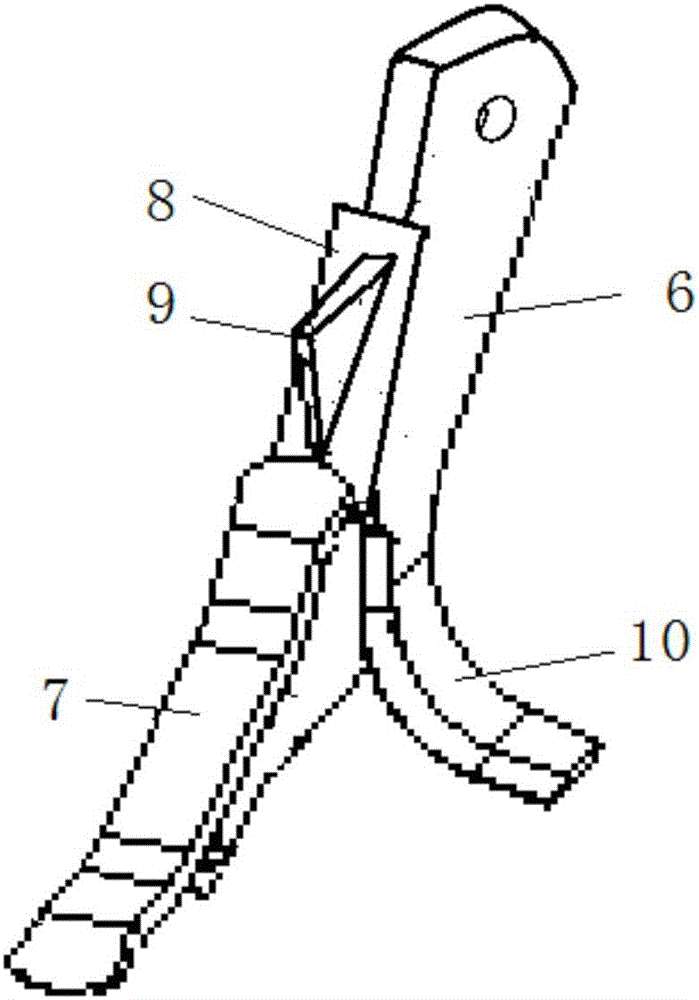

[0024] The front subsoil pear tip assembly 3 and the rear subsoil subsoil assembly 4 have the same structure, and both include the ploughshare 6 facing the direction of travel of the omni-directional subsoiler. The front end of the ploughshare 6 is wedge-shaped, and the ploughshare 6 is wedge-shaped The upper end of the section is provided with a front turning board 7 inserted into the soil. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com