A kind of steel fiber directionally reinforced ultra-high performance concrete forming device and using method thereof

A directional reinforcement, ultra-high-performance technology, applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of uniform unidirectional distribution of steel fibers, high requirements for magnetic induction intensity, random distribution of steel fibers, etc., to achieve Realize directional distribution, improve the effect of directional distribution, and improve the effect of strengthening and toughening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

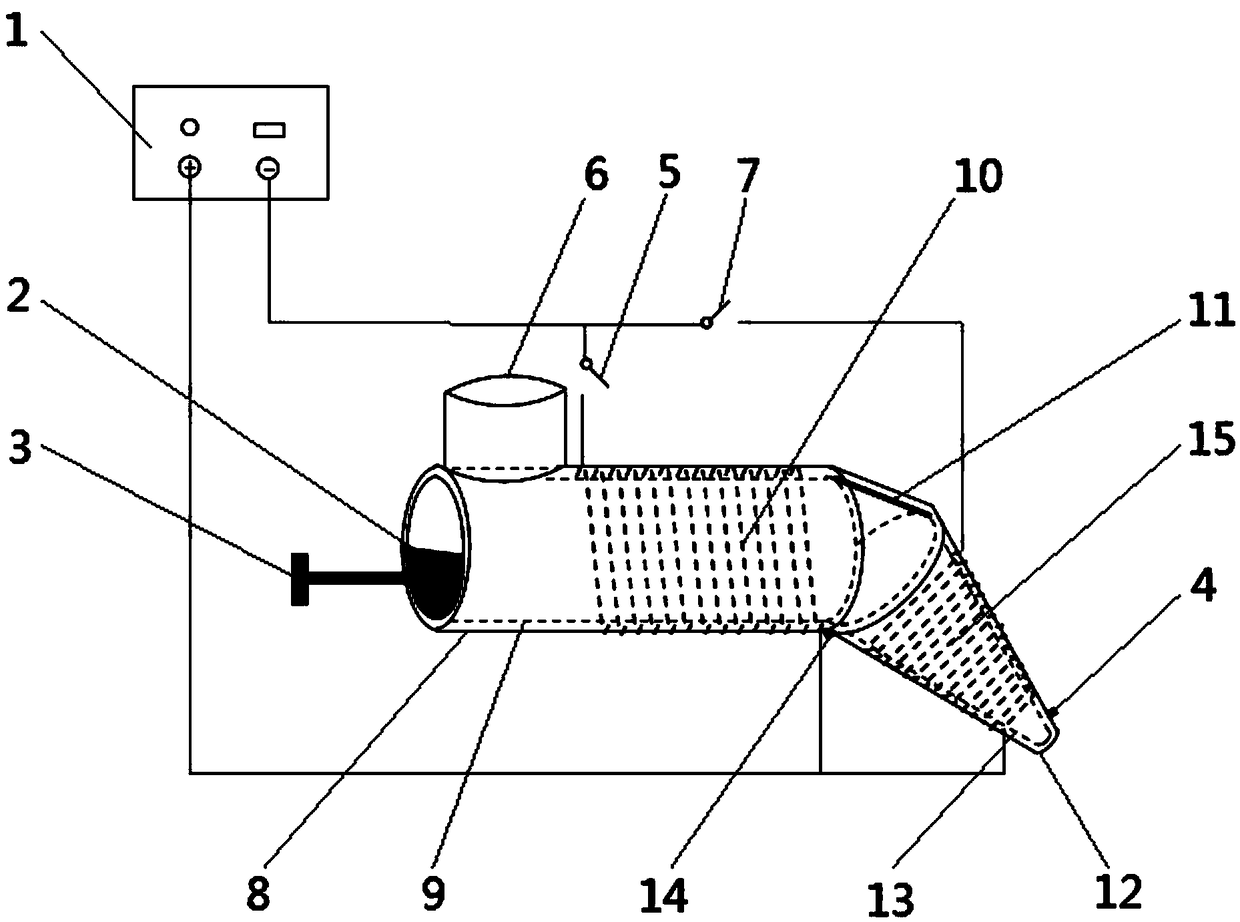

[0010] Specific implementation mode one: combine figure 1 Description of this embodiment, a forming device for steel fiber directionally reinforced ultra-high performance concrete in this embodiment consists of a DC power supply 1, a piston 2, a push rod 3, a first switch 5, a feeding cylinder 6, a second switch 7, a cylindrical Flow channel, corner flow channel and truncated conical flow channel; described cylindrical flow channel is made up of cylindrical outer tube 8, cylindrical inner tube 9 and first coil 10; , a frustum-shaped inner cylinder 13 and a second coil 15; a baffle 11 is arranged in the corner flow passage; the cylindrical flow passage is arranged horizontally, and one end of the cylindrical flow passage is provided with a frustum-shaped flow passage. An included angle is formed between the cylindrical flow channel and the truncated conical flow channel, and the included angle is 90°~135°; a corner flow channel is set between the cylindrical flow channel and th...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the piston 2, the push rod 3, the feed cylinder 6, the cylindrical outer cylinder 8, the cylindrical inner cylinder 9, the baffle plate 11, the circular The materials of the frustum-shaped outer cylinder 12 and the frustum-shaped inner cylinder 13 are all high-strength materials that are not attracted by magnetic force. Others are the same as the first embodiment.

[0016] The high-strength materials that are not magnetically adsorbed are engineering plastics, glass, ceramics, organic glass, and the like.

specific Embodiment approach 3

[0017] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the output voltage of the DC power supply 1 is 0-30V, and the output current is 0-20A. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com