Ultra-high toughness cement-based composite material extrusion directional mixer and extrusion method

An ultra-high toughness, composite material technology, applied in ceramic extrusion dies, climate change adaptation and other directions, can solve the problems of reinforced concrete structure sustainability, fiber can not play the role of bridging, brittle failure and other problems, to enhance toughness, The effect of improving the extrusion orientation effect and the effect of improving the strain hardening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

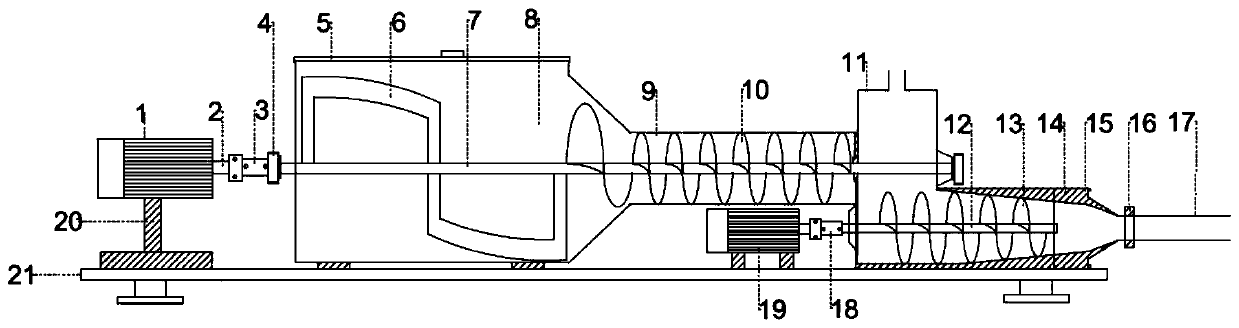

[0052] figure 1 It is a structural schematic diagram of an ultra-high toughness cement-based composite material extrusion directional mixer, which can be divided into the following two parts except for the bracket 21 used to support each structure.

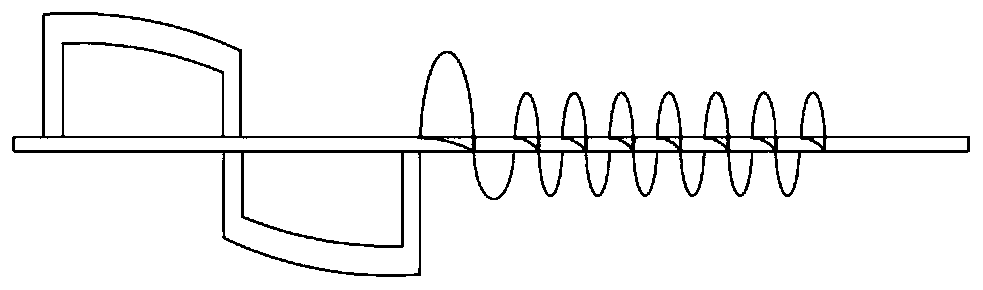

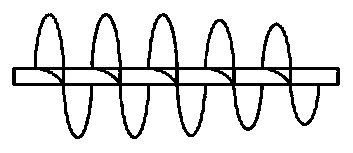

[0053] The first propulsion part is composed of the following parts. The first motor 1 of the first driving device is horizontally arranged on the bracket 21 , the first motor 1 is fixed on the bracket 21 through the bracket 20 , and the first motor 1 can be driven to rotate clockwise and counterclockwise. A mixing chamber 8 is arranged horizontally, and a shielding cover 5 is set above the mixing chamber to prevent dust or material from being carried out during the material stirring process. The first discharge cylinder 9 is horizontally connected with the mixing chamber 8; the first transmission shaft 7 is arranged horizontally between the mixing chamber 8 and the first discharge cylinder 9, and the first transmission shaft 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com