High-strength calcium silicate board and preparation process thereof

A calcium silicate board, high-strength technology, applied in the field of calcium silicate board, can solve problems such as irregular distribution of fibers, difficult orientation of the board, and affecting the strength of the board, so as to improve the steric hindrance, expand the field of use, The effect of increasing the strength of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

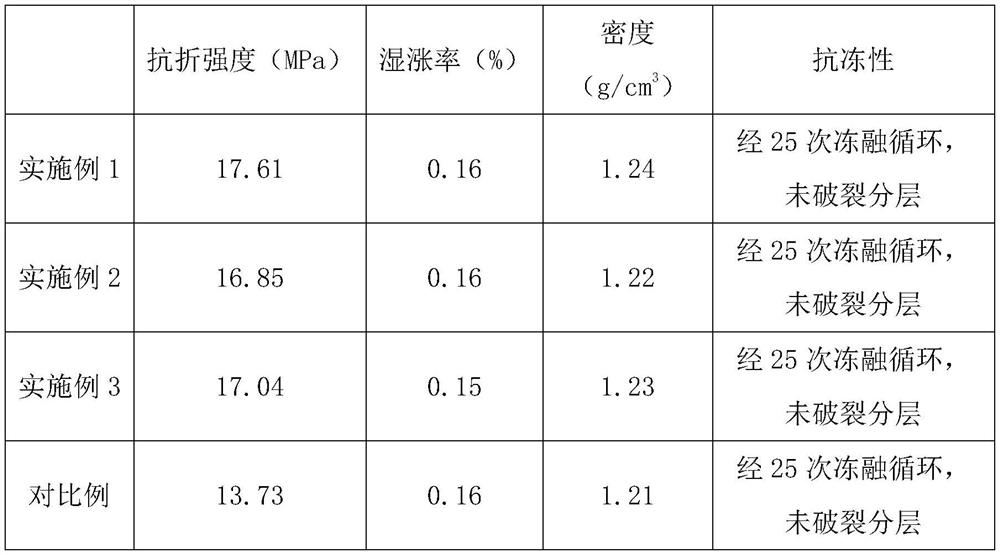

Examples

Embodiment 1

[0027] A high-strength calcium silicate board is made of the following raw materials: 9kg of phosphogypsum, 13.5kg of diatomite, 24kg of quartz sand, 9kg of calcium carbide mud, 13kg of lime, and 8kg of iron-doped wood fiber.

[0028] The preparation method of described iron-doped wood fiber comprises the following steps:

[0029] (1) Using a DC arc plasma method, using a tungsten rod as a cathode, an iron block as an anode, 0.02MPa argon and 0.02MPa hydrogen as a reaction gas, and a DC arc plasma as a heat source to evaporate the iron block to obtain iron nanoparticles;

[0030] (2) Add the above-mentioned iron nanoparticles to 10% silane coupling agent KH550 ethanol solution, control m(Fe):m(KH550)=15:1, adjust the pH to 5.0, and then add iron nanoparticles equivalent to it The wood fiber with a length of 1.0-2.5 mm which is 300 times the mass of the particle is stirred at 60° C. for 60 minutes, centrifuged and washed until neutral after completion, and dried to obtain the i...

Embodiment 2

[0036] A high-strength calcium silicate board made of the following raw materials: 8kg of phosphogypsum, 11kg of diatomaceous earth, 22kg of quartz sand, 8kg of calcium carbide mud, 10kg of lime, and 6kg of iron-doped wood fiber.

[0037] The preparation method of described iron-doped wood fiber comprises the following steps:

[0038] (1) Using a DC arc plasma method, using a tungsten rod as a cathode, an iron block as an anode, 0.02MPa argon and 0.02MPa hydrogen as a reaction gas, and a DC arc plasma as a heat source to evaporate the iron block to obtain iron nanoparticles;

[0039] (2) Add the above-mentioned iron nanoparticles to 10% silane coupling agent KH550 ethanol solution, control m(Fe):m(KH550)=15:1, adjust the pH to 4.5, and then add iron nanoparticles equivalent to it Wooden fibers with a length of 1.0-2.5mm that are 200 times the mass of the particles are stirred at 55°C for 80 minutes, centrifuged and washed to neutrality after completion, and dried to obtain iro...

Embodiment 3

[0045] A high-strength calcium silicate board is made of the following raw materials: 10kg of phosphogypsum, 15kg of diatomaceous earth, 26kg of quartz sand, 10kg of calcium carbide mud, 16kg of lime, and 10kg of iron-doped wood fiber.

[0046] The preparation method of described iron-doped wood fiber comprises the following steps:

[0047] (1) Using a DC arc plasma method, using a tungsten rod as a cathode, an iron block as an anode, 0.02MPa argon and 0.02MPa hydrogen as a reaction gas, and a DC arc plasma as a heat source to evaporate the iron block to obtain iron nanoparticles;

[0048](2) Add the above-mentioned iron nanoparticles to 10% silane coupling agent KH550 ethanol solution, control m(Fe):m(KH550)=15:1, adjust the pH to 5.5, and then add iron nanoparticles equivalent to it The wood fiber with a length of 1.0-2.5 mm which is 400 times the mass of the particle is stirred at 65° C. for 40 minutes, centrifuged and washed until neutral after completion, and dried to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com