Vacuum maintaining type feces-collection system with separator

A technology of vacuum maintenance and separator, which is applied in the direction of crew equipment, ships, toilet accessories, etc. It can solve the problems of passenger inconvenience, waiting for a long time, and the dirt box cannot always maintain a vacuum state, so as to achieve retention performance and improve work environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

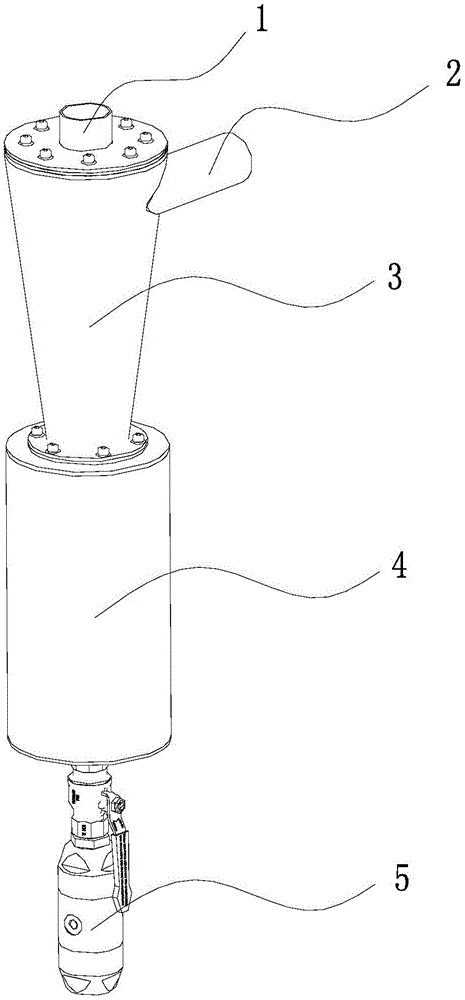

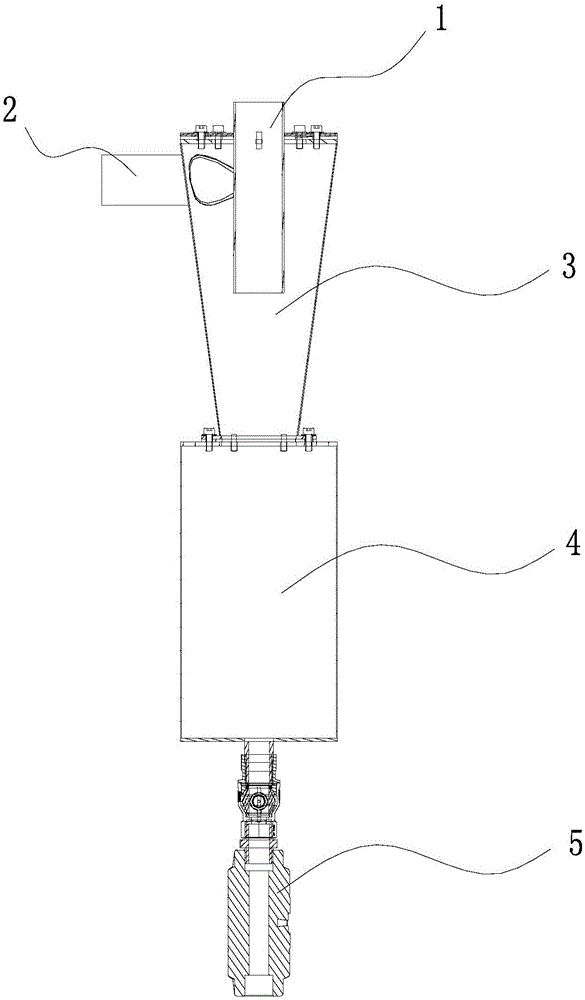

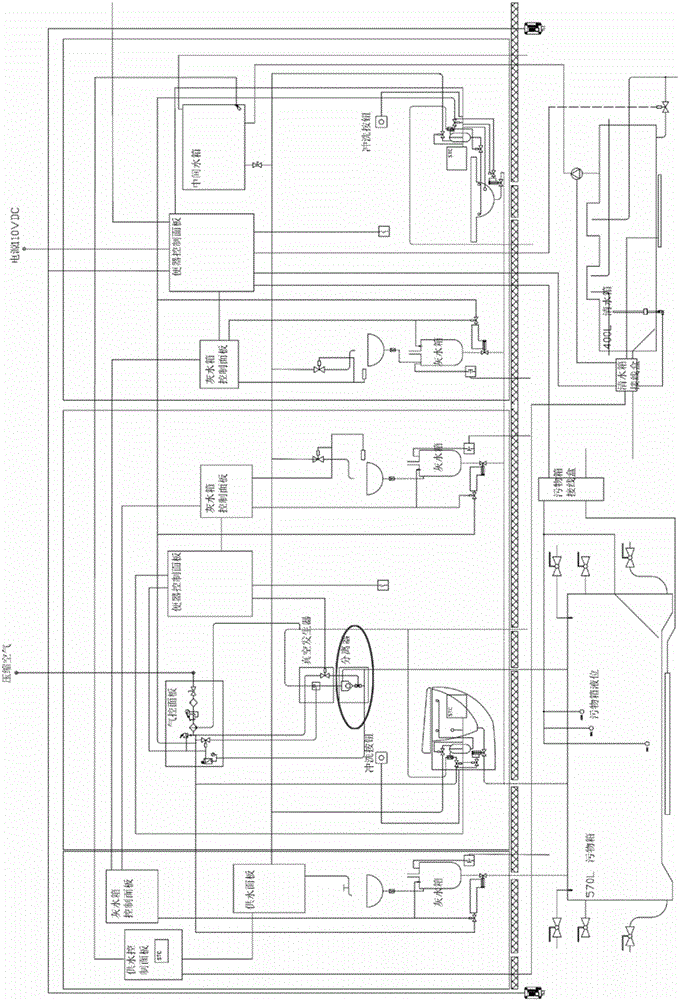

[0028] The block diagram of the vacuum holding type toilet collection system provided by this embodiment is as follows: image 3 As shown, it is a schematic diagram of a system block diagram including two toilets. figure 1 for image 3 Schematic diagram of the separator, figure 2 for figure 1 Schematic cross-section of the separator in . It should be noted, image 3 For example only, more than two toilets are also possible.

[0029] see Figure 1 to Figure 4 As shown, the present embodiment provides a vacuum holding type feces collection system with a separator, including a toilet 6, a vacuum generator 9, a separator 3 and a dirt box 7, and the toilet 6 is connected to the dirt b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com