Intelligent pneumatic solid rim lubricating system and lubricating method

A lubricating system and rim technology, which is applied in the field of intelligent pneumatic solid rim lubrication system and rim lubrication, can solve the problems of spring failure, high lubrication cost, and high price of lubricating blocks, and achieve the effect of avoiding excessive lubrication and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The illustrative and non-limiting embodiments of the present invention will be described in detail below with reference to the accompanying drawings, and the intelligent pneumatic solid rim lubrication system and lubrication method according to the present invention will be further described.

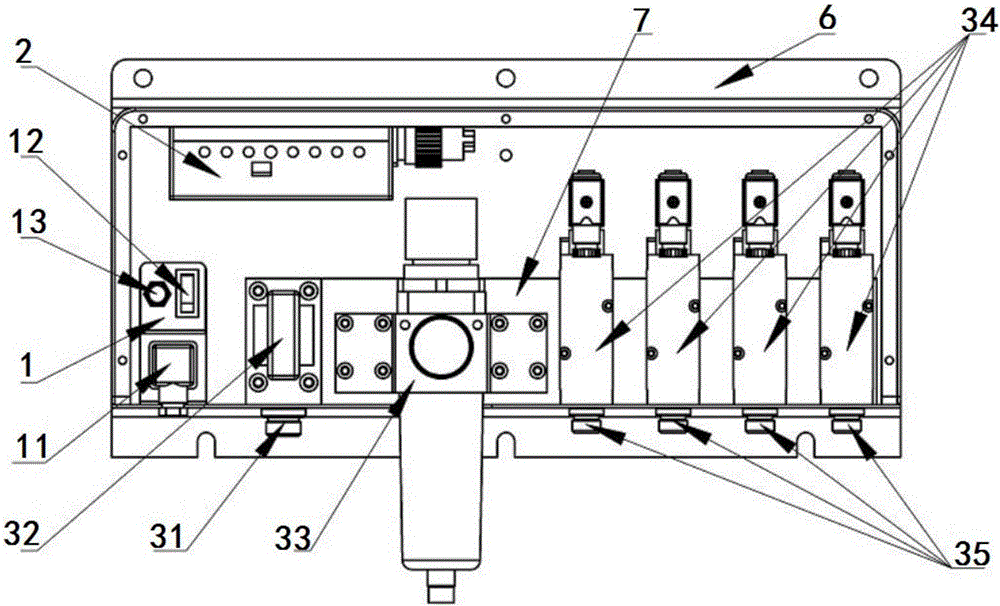

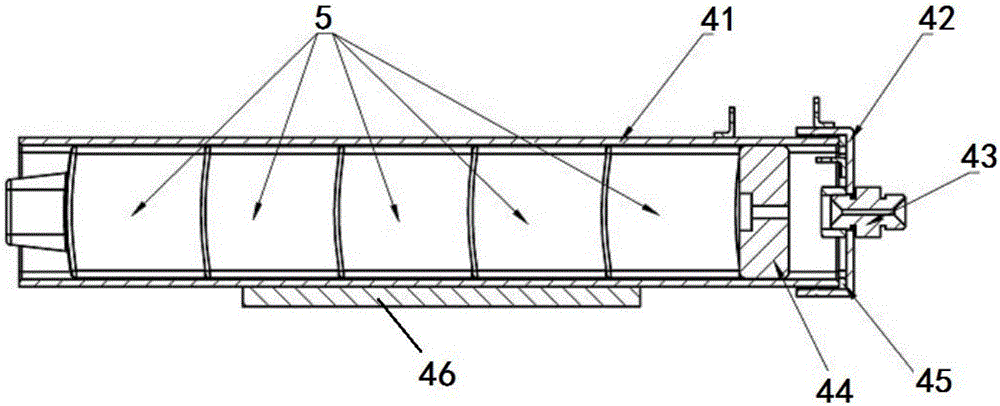

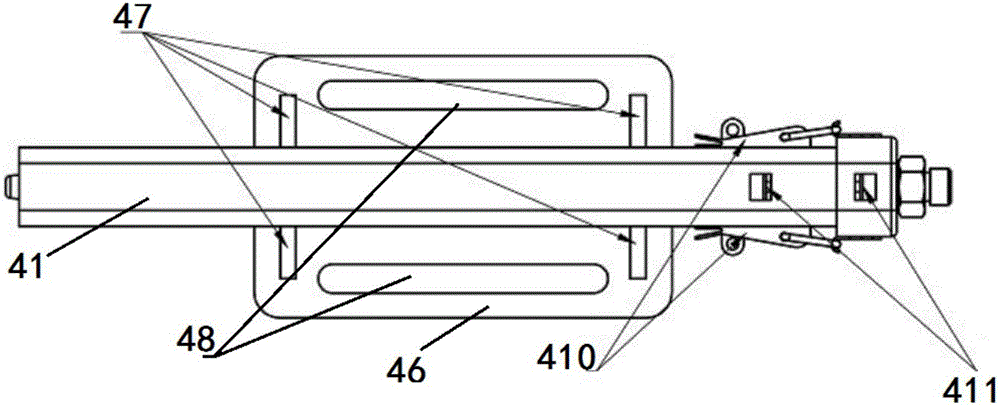

[0078] One aspect of the present invention proposes a kind of intelligent pneumatic solid rim lubricating system, and this system comprises control system and a plurality of lubricating mechanism 4 that is connected with control system (each in a plurality of lubricating mechanism 4 comprises shell, rear cover 42 And the piston 44, wherein the housing includes a cylinder 41). Refer below figure 1 and 2 This intelligent pneumatic solid rim lubrication system is described in detail.

[0079] refer to figure 1 , the control system includes a power supply module 1, an electric controller 2 and a pneumatic actuator 3 (a pneumatic actuator 3 intake joint 31, a cut-off plug 32, a dec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com