High temperature and strong acid corrosion resistant insulating material for electrically controlled solid propellant electrodes

A technology of solid propellant and insulating material, applied in the field of materials, can solve the problems of weak acid corrosion resistance, insufficient high temperature resistance, poor insulation, etc., and achieve the effects of high working temperature, strong wear resistance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

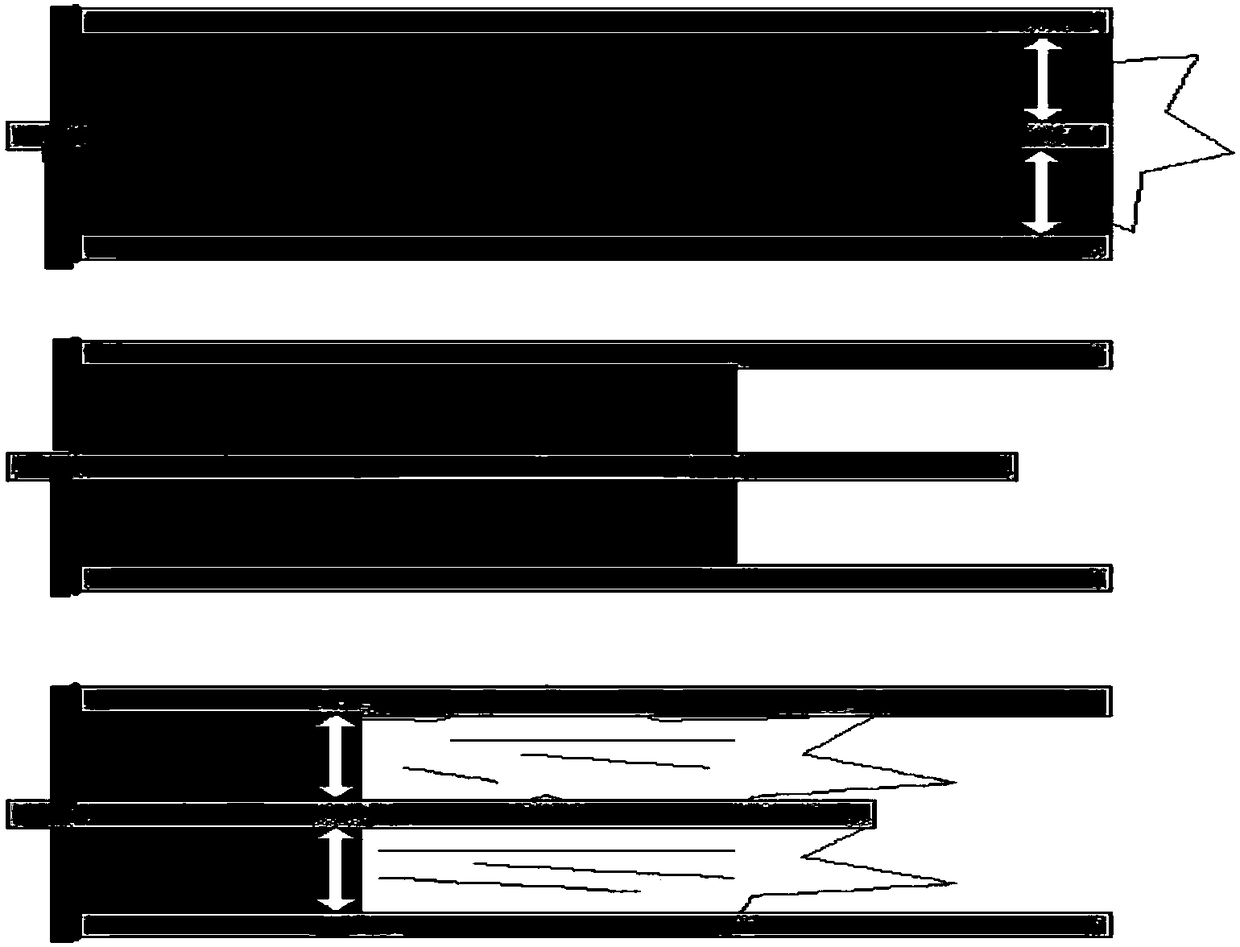

Method used

Image

Examples

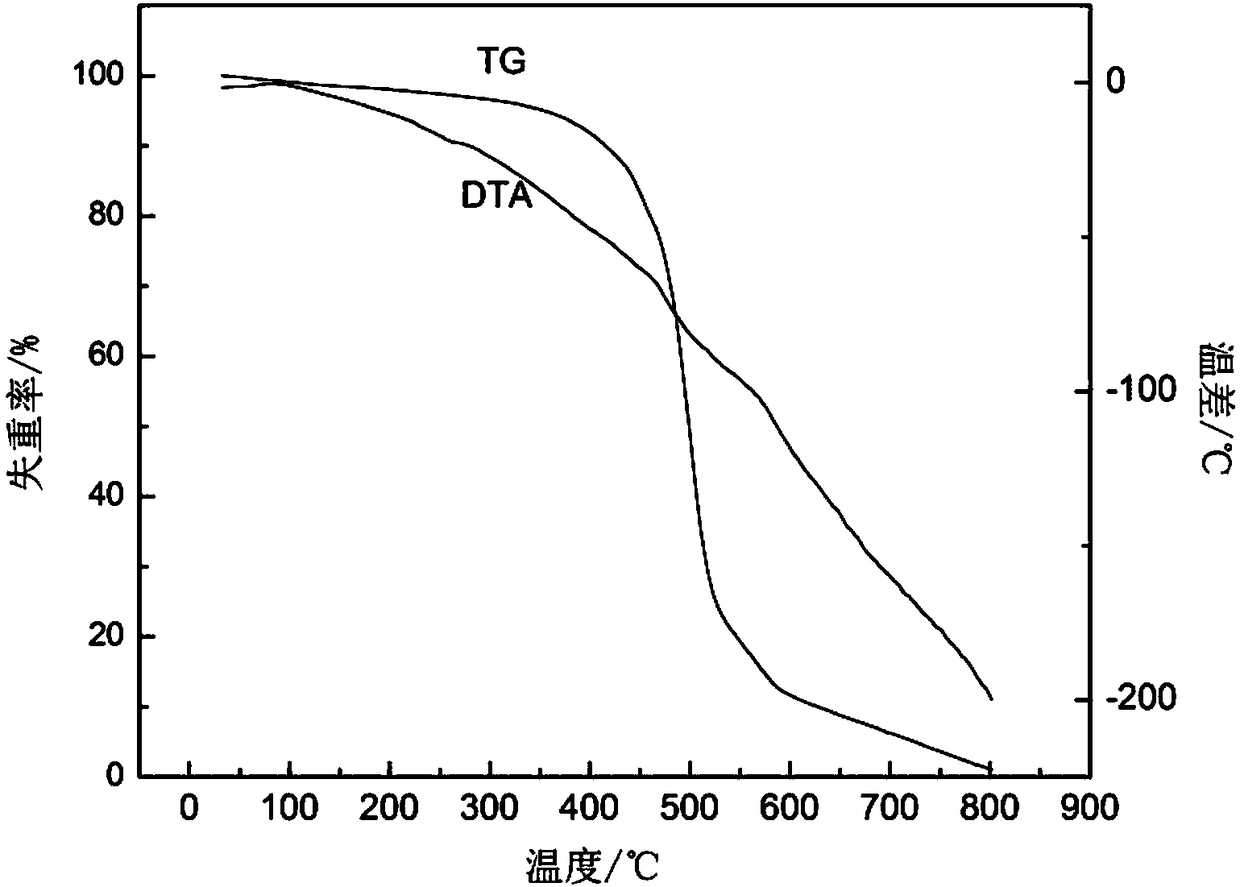

Embodiment 1

[0045] A high-temperature-resistant and strong-acid-resistant insulating material for an electrically controlled solid propellant electrode, characterized in that it includes the raw materials and parts by weight as shown in Table 1:

[0046] Table 1

[0047]

[0048]

[0049] The leveling agent is one or both of polypropylene or polyurethane; the curing agent is one of acid anhydride curing agent, triphenylphosphine or boron amine epoxy curing agent; the surface The active agent is one of lignosulfonate or polyoxyethylene;

[0050] A method for preparing a high-temperature-resistant and strong-acid corrosion-resistant insulating material for an electrically controlled solid propellant electrode, characterized in that it comprises the following steps:

[0051] 1) Dissolving the weighed polyphenylene sulfide and polyvinyl alcohol in their respective solvents;

[0052] The solvent of the polyphenylene sulfide is a mixture of water, ethanol and surfactant;

[0053] The s...

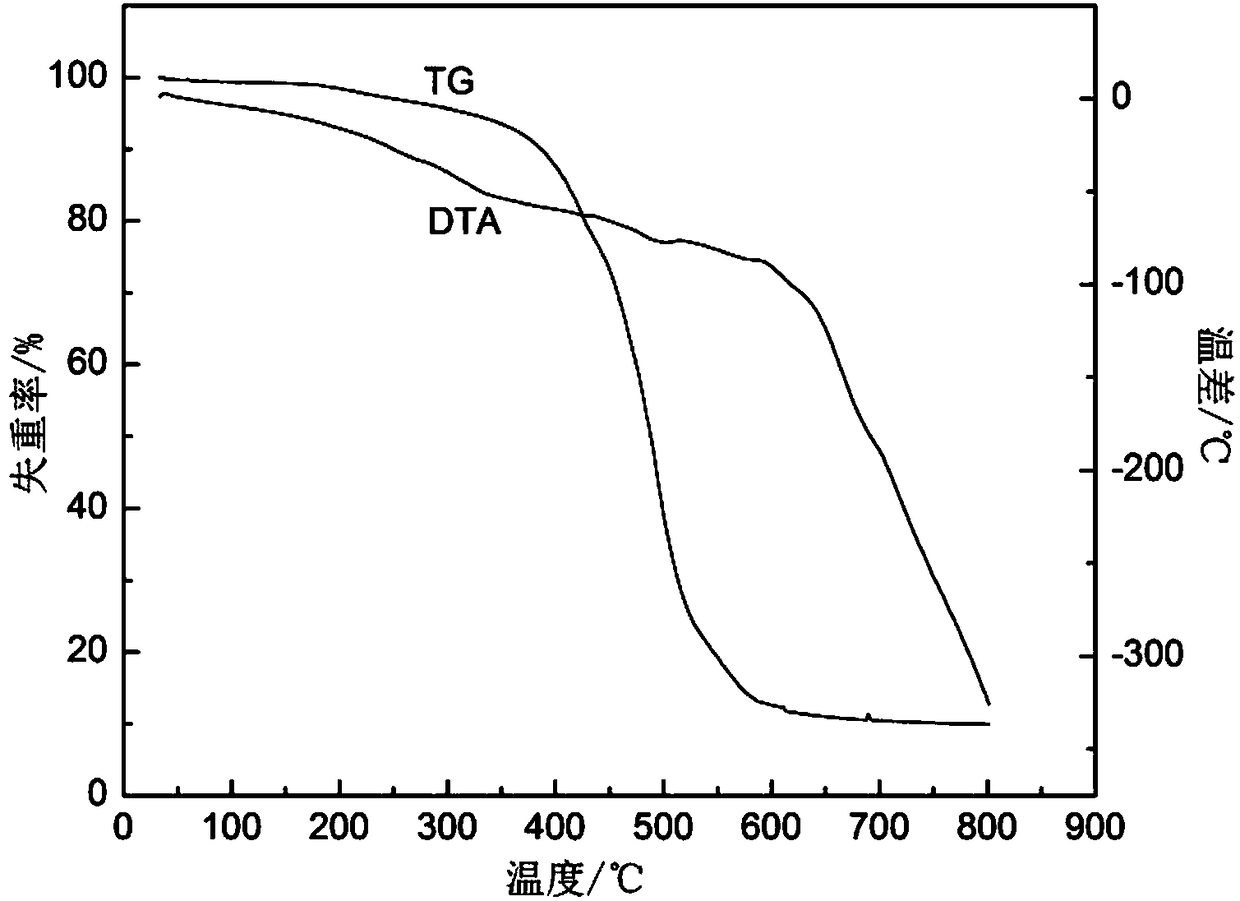

Embodiment 2

[0070] A high-temperature-resistant and strong-acid corrosion-resistant insulating material for an electrically controlled solid propellant electrode is characterized in that it includes raw materials and parts by weight as shown in Table 2:

[0071] Table 2

[0072] raw material

number of copies

raw material

number of copies

PTFE suspension

55 copies

magnesium hydroxide

3 copies

epoxy resin

30 copies

Oxidized polyethylene wax

1 copy

polyvinyl alcohol

5 copies

stearic acid

1 copy

Polyphenylene sulfide

0 copies

n-octanol

2 copies

Polyimide

10 copies

Titanate coupling agent

1 copy

Nano Titanium Dioxide

1 copy

leveling agent

0.8 parts

Ultrafine Calcium Carbonate

2 copies

Hardener

3 copies

Molybdenum disulfide

2 copies

Surfactant

0 copies

[0073] The leveling agent is one or both of polypropylene or polyur...

Embodiment 3

[0093] A high-temperature-resistant and strong-acid corrosion-resistant insulating material for an electrically controlled solid propellant electrode, characterized in that it includes the raw materials and parts by weight as shown in Table 3:

[0094] table 3

[0095] raw material

number of copies

raw material

number of copies

PTFE suspension

50 copies

magnesium hydroxide

3 copies

epoxy resin

25 copies

Oxidized polyethylene wax

1 copy

polyvinyl alcohol

5 copies

stearic acid

1 copy

Polyphenylene sulfide

10 copies

n-octanol

2.5 servings

Polyimide

10 copies

Titanate coupling agent

1.5 servings

Nano Titanium Dioxide

1 copy

leveling agent

1 copy

Ultrafine Calcium Carbonate

2 copies

Hardener

2.5 servings

Molybdenum disulfide

2 copies

Surfactant

0.2 parts

[0096] The leveling agent is one or both of polyprop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com