A dip-molding product of an electrically controlled solid propellant electrode and a preparation method thereof

A solid propellant and electrode technology, applied in the direction of plastic/resin/wax insulators, anti-corrosion coatings, coatings, etc., can solve the problems of poor high temperature resistance of the insulating layer, complex processing technology, insufficient adhesion, etc., and achieve high insulation performance , The preparation process is simple, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

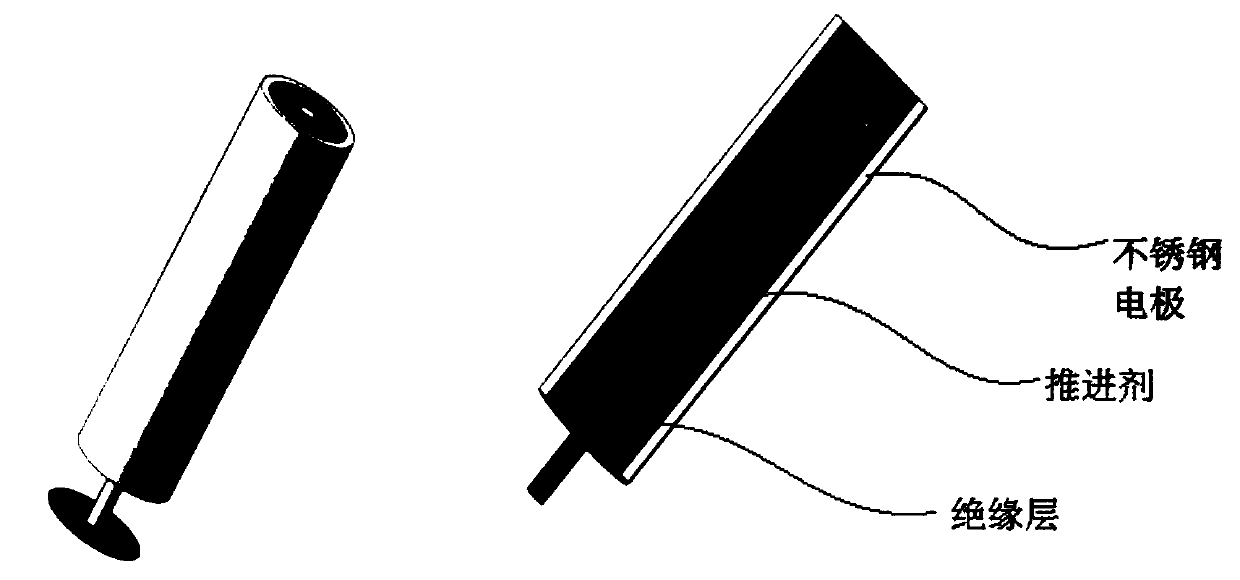

Image

Examples

Embodiment 1

[0040] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 1:

[0041] Table 1

[0042]

[0043]

[0044] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0045] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0046] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0047] The stirring rate is 300r / min, and the stirring time is 60min;

[0048] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0049] 4) Under normal temperature conditions, immerse the electrode s...

Embodiment 2

[0055] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 3:

[0056] table 3

[0057]

[0058] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0059] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0060] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0061] The stirring rate is 350r / min, and the stirring time is 60min;

[0062] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0063] 4) Under normal temperature conditions, immerse the electrode substrate in ...

Embodiment 3

[0069] An electronically controlled solid propellant electrode dip-molding product, characterized in that it includes the raw materials and parts by weight as shown in Table 5:

[0070] table 5

[0071]

[0072]

[0073] A method for preparing an electronically controlled solid propellant electrode impregnated product, characterized in that it comprises the following steps:

[0074] 1) Pass the phenolic resin or the mixed system in the weighed raw materials through a 120 mesh sieve, disperse evenly, mix with inorganic fillers, plasticizers, and coupling agents to obtain mixture A;

[0075] 2) Add a mixed solvent into the mixture A, and stir under vacuum to obtain a uniformly stirred mixture B;

[0076] The stirring rate is 400r / min, and the stirring time is 40min;

[0077] 3) Add dispersant, defoamer, and leveling agent in sequence to mixture B, stir until mixed evenly, and obtain dipping liquid;

[0078] 4) Under normal temperature conditions, immerse the electrode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com