A Cable Forming Process of High Molecular Polyethylene Fiber Coated Sheath

A technology of high molecular polyethylene and forming process, which is applied in the direction of textile cables, rope-making auxiliary devices, textiles and papermaking, etc. It can solve the problems of wear-resistant sheath wrinkling, stacking, hard cables, etc., and avoid obstacles to use , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Equipment preparation: install the shaping device.

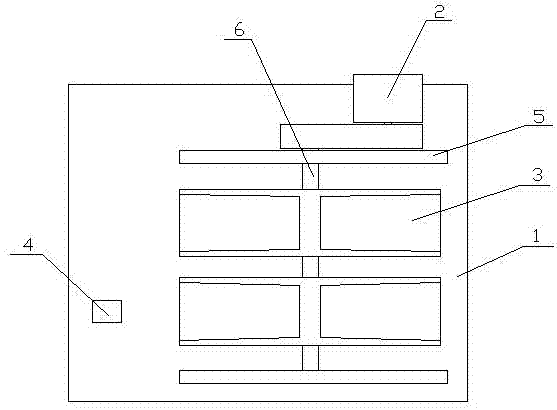

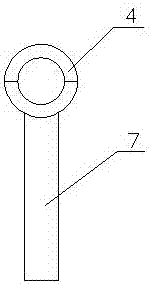

[0017] Such as figure 1 , 2 As shown, the specific structure of the shaping device is: comprising a frame 1, a reduction motor 2, a rope reel 3, an annular restraint body 4, two supporting side plates 5 are arranged on the frame 1, and the reduction motor 2 is fixed on the frame 1, The output shaft end of the reduction motor 2 is connected to the transmission shaft 6, the transmission shaft 6 is supported between two supporting side plates 5, the rope reel 3 is fixed on the transmission shaft 6, and the annular constraint body 4 is fixed on the frame 1 through the support arm 7 , the annular constraining body 4 is set correspondingly to the rope reel 3 .

[0018] 2. Cable forming process of polymer polyethylene fiber sheath:

[0019] 1. Left-twisting multiple high-molecular polyethylene fibers to form a left-twisted strand with a diameter of 6-30 mm, and right-twisting multiple high-molecular polyethylene fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com