Environment-friendly dismantling construction method for two-layer steel sheet pile and soil core composite cofferdam

A technology combining cofferdams and construction methods, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of large influence on the surrounding, easy to collapse, slow construction speed, etc., and achieve less environmental pollution, less difficulty, and more economical The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

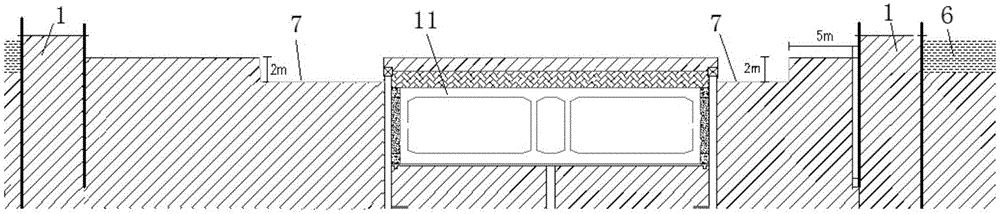

[0033] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

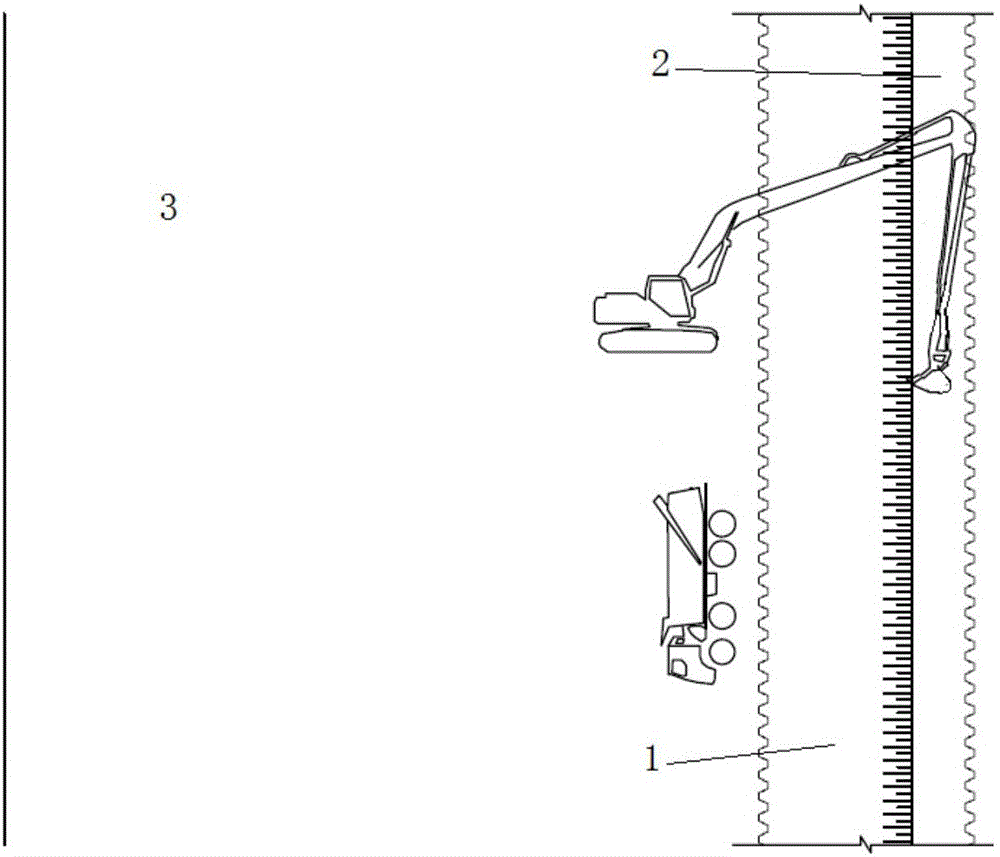

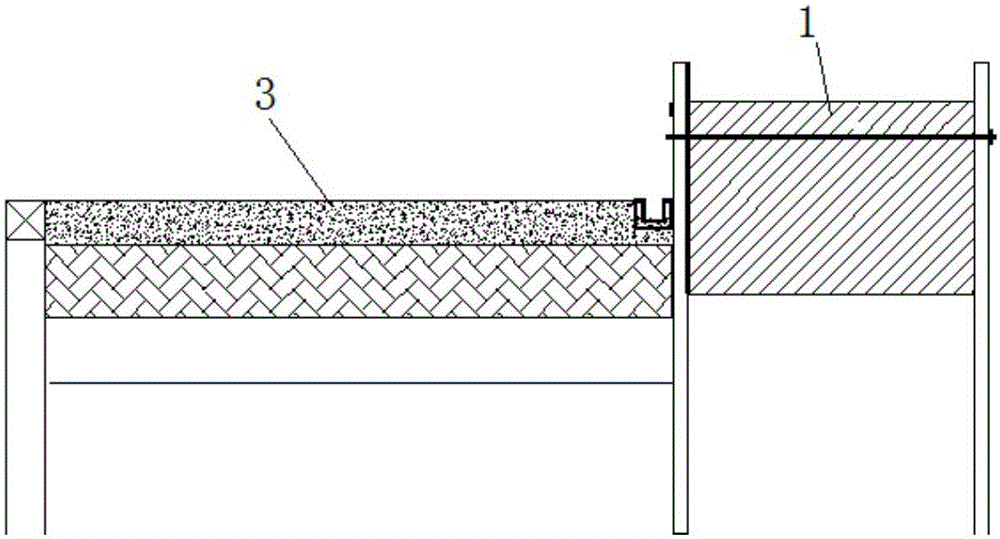

[0034] The environmental protection demolition construction method of the double-layer steel sheet pile soil core composite cofferdam shown in the figure is specifically carried out according to the following steps:

[0035] a Clean up the garbage in the cofferdam field and remove the sub-cofferdam;

[0036] b. Destroy the construction access road: take the method of separation and segmented interval removal, and replace the access road within a certain range near the cofferdam while digging;

[0037] c. Digging the foundation pit for the core soil: calculate the size of the foundation pit that needs to accommodate the core soil according to the core soil, and excavate at a certain distance from the cofferdam;

[0038] d cofferdam backwater: return the cofferdam to the lake level;

[0039] e Pull out the steel sheet pile on the back surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com