Mechanical anti-theft lock and opening device and well cover applied to well cover

A technology of mechanical anti-theft locks and manhole covers, which can be used in water conservancy projects, artificial islands, underwater structures, etc. It can solve the problems of difficulty in illegal opening of lock bodies, easy rusting of manhole cover locks, and inconvenient operation, and achieve the difficulty of illegal opening High, anti-theft, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

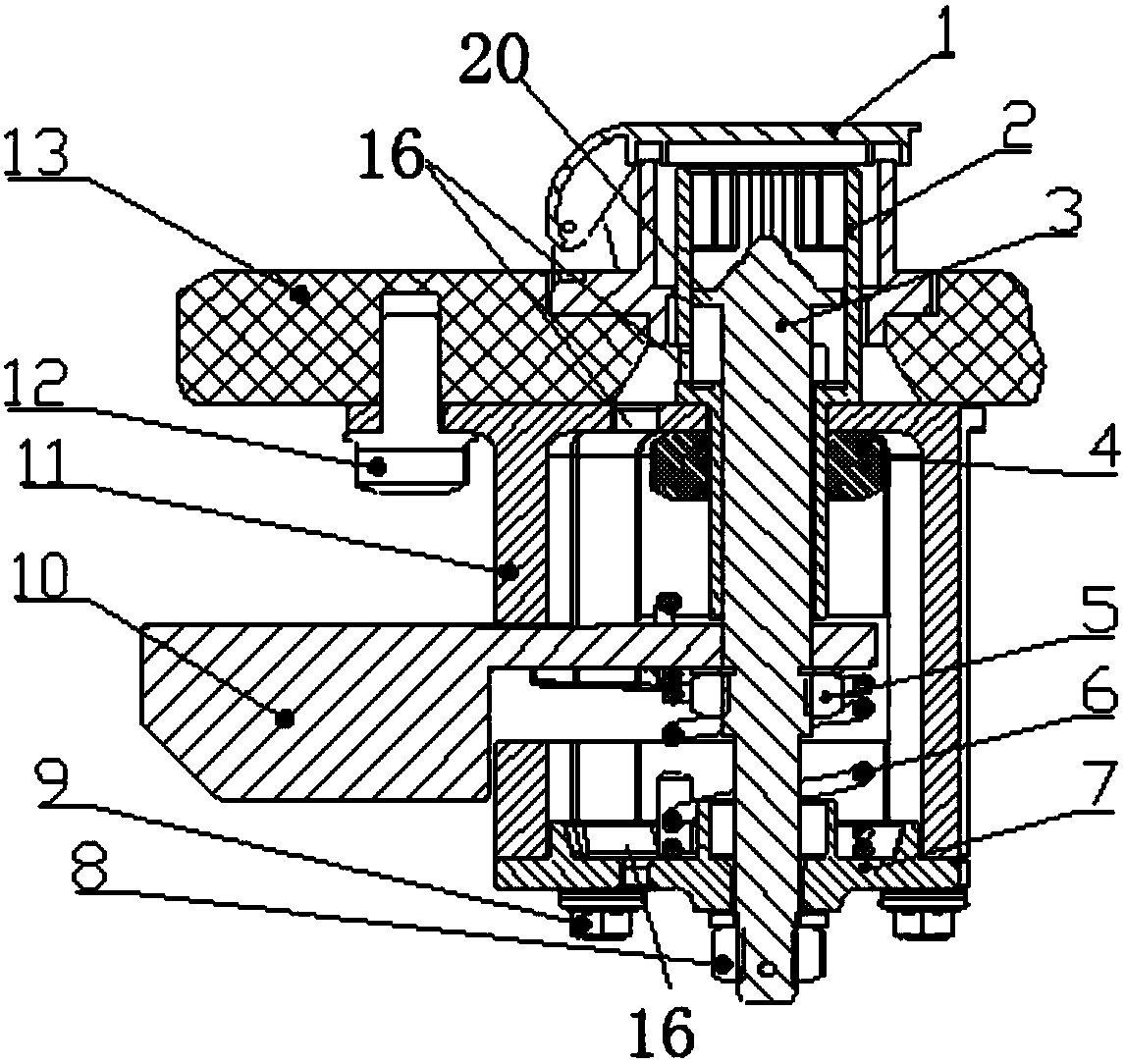

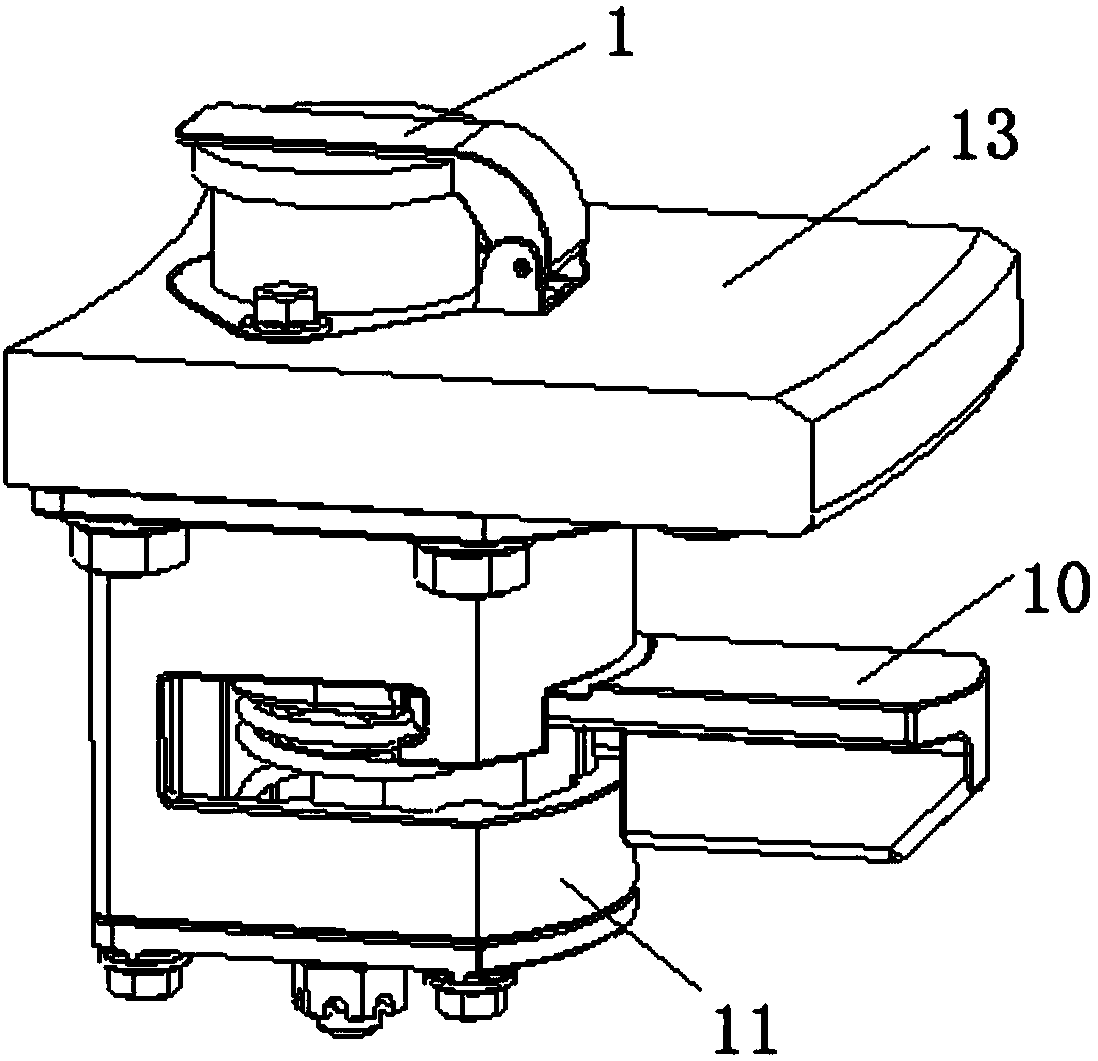

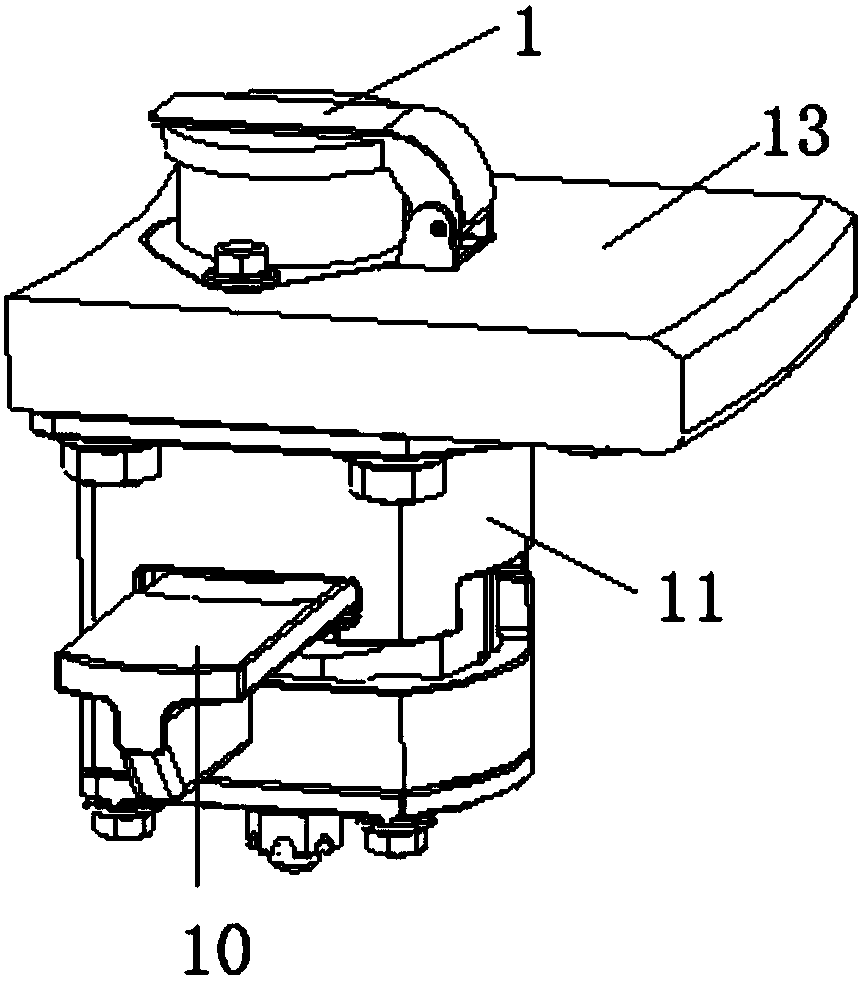

[0038] Such as Figure 1-Figure 6 As shown, a mechanical anti-theft lock applied to a manhole cover includes a dust cover 1, a lock sleeve 2, a lock cylinder 3, a lock case 11, a lock bottom 7, a lock tongue 10, and a torsion spring 6. The lock case 11 is provided with a lock sleeve 2 and a lock cylinder 3. The entire lock body is fastened to the back of the well cover 13 through the lock case 11. The front of the well cover 13 is equipped with a dust cover 1 to protect the lock sleeve 2 and prevent the intrusion of dust and sand. . The lock sleeve 2 is installed on the lock housing 11, and the lock sleeve 2 is fastened to the lock housing 11 through the nut I4. The flat mouth on the lock housing 11 limits the rotation of the lock sleeve 2. Turn inside the set 2. One end of the deadbolt 10 is sleeved on the lock cylinder 3, and the other end passes through the opening of the lock housing 11 to block the well ring and prevent the well cover from being opened. The deadbolt 10...

Embodiment 2

[0048] Such as Figure 7 As shown, a kind of opening device that cooperates with the mechanical anti-theft lock includes a handle 17, the handle 17 is vertically connected with the rotating shaft 18, the bottom of the rotating shaft 18 is provided with a concave surface matching the convex surface of the lock cylinder 3, and the rotating shaft 18 surrounds The concave surface is provided with a groove matched with the bump 20 . In this embodiment, the groove is set as a serrated groove matching with the serrated protrusion 20 of the lock core 3 , and the groove is used to clamp the protrusion 20 of the lock core 3 to drive the lock core 3 to rotate. The top of the lock core 3 is a convex surface, and the corresponding front end of the rotating shaft 18 is a concave surface. The design of the zigzag protrusion and the groove greatly improves the difficulty of counterfeiting keys and illegal opening.

Embodiment 3

[0050] A well cover with a mechanical anti-theft lock includes a well cover body, which is fixedly connected to the lock housing 11 of the mechanical anti-theft lock in Embodiment 1.

[0051] The mechanical anti-theft lock of the present invention uses two 90° openings on the torsion spring 6 and the lock housing 11 to realize the state of locking and opening; The bumps on the core are used to prevent theft.

[0052] Way of working:

[0053] When opening the mechanical anti-theft lock: first lift the dust cover 1, insert the opening device into the lock sleeve 2, when inserting, match the serrated groove of the opening device with the serrated groove of the lock sleeve 2, after inserting, the opening device The serrated groove catches the protrusion of the lock cylinder 3, first turn the opening device clockwise until it stops, at this time the bolt 10 is separated from the first opening 14, and then press down on the opening device to drive the lock cylinder 3 to overcome th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com