LED bulb having excellent ventilating and heat dissipation functions

A technology of LED light bulbs and functions, which is applied in the direction of lighting and heating equipment, components of lighting devices, semiconductor devices of light-emitting elements, etc., which can solve the problem of affecting the luminous efficiency and working life of light bulbs, unsatisfactory economy and practicability, and corrosion of LEDs. Light strips and other issues to ensure reliable working life and lighting effects, simple and scientific structure, and improve heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

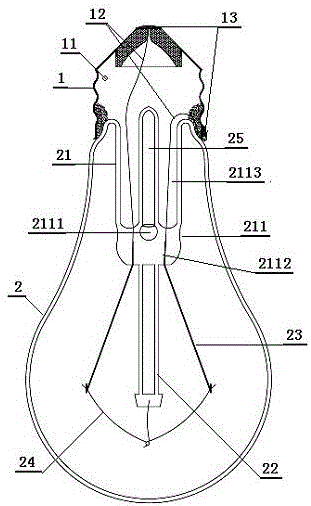

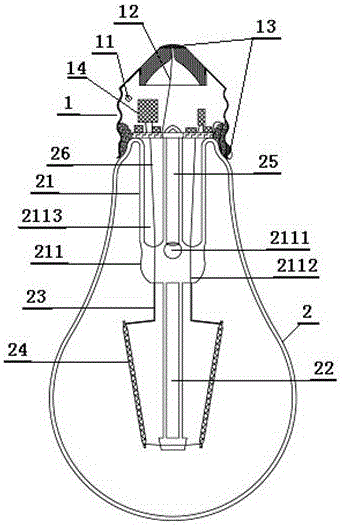

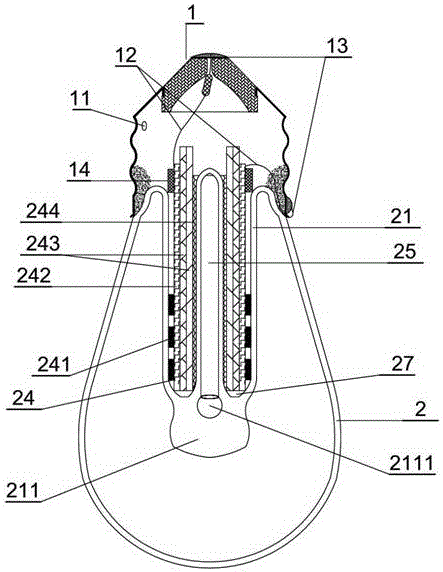

[0021] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

[0022] exist image 3 Among them, the main body of the LED light bulb with excellent ventilation and heat dissipation functions of the present invention is composed of a lamp cap 1 and a glass bulb 2 bonded together with glue. The point 13 and the LED power drive assembly 14 electrically connected to the other end of the energized guide wire A 12 are characterized in that a glass stem tube 21, an electroluminescent assembly 24 and an exhaust pipe 25 are arranged in the cavity of the glass bulb shell 2, in:

[0023] The main body of the glass stem tube 21 is in the shape of a deep cylinder, and the bottom of the cylinder is composed of a stem head 211 provided with a filling and venting hole 2111. The center of the cylinder cavity is provided with a position corresponding to the position of the charging and venting hole 2111. Corresponding to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com