Light guide light-leakage preventing structure for car lamp

A light guide and light leakage technology, which is applied in the field of auto parts, can solve the problems affecting the appearance of light guide lighting lamps, light emission, assembly errors, etc., and achieve the effect of reducing light emission, high practicability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further elaborated in conjunction with the accompanying drawings.

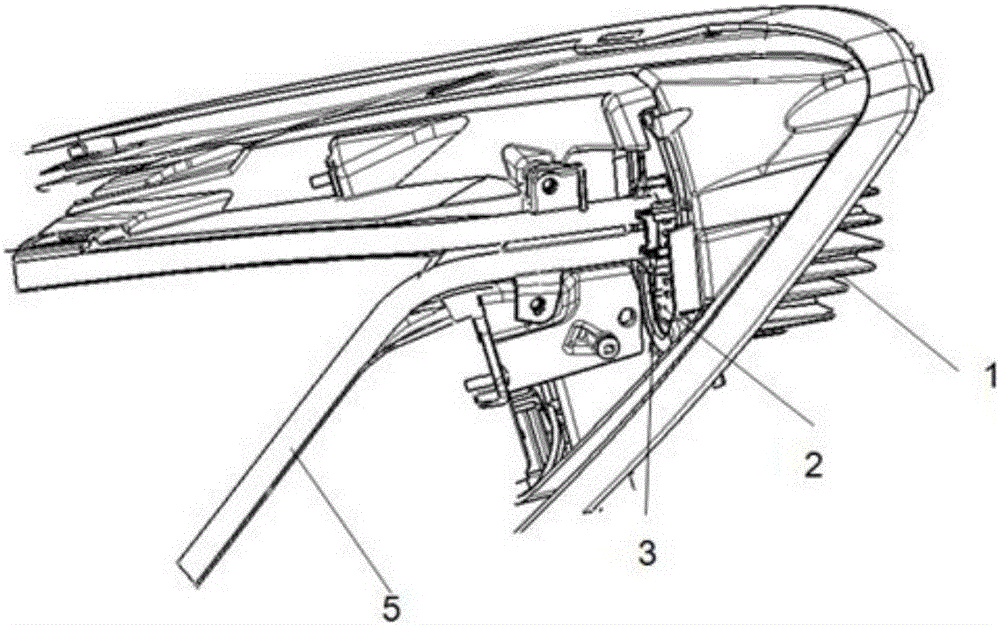

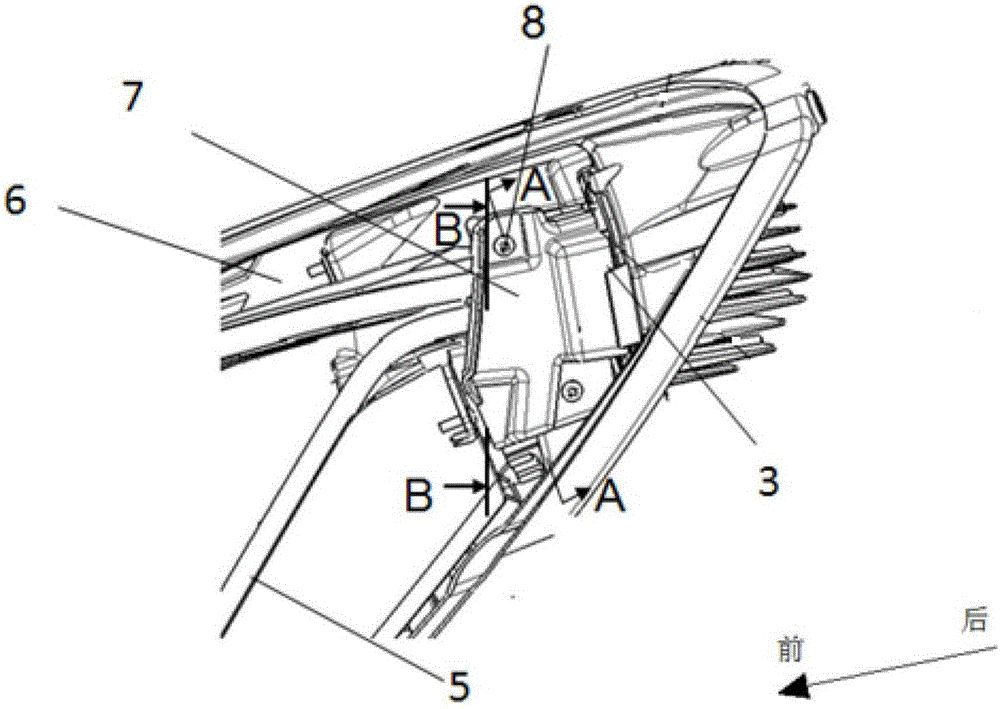

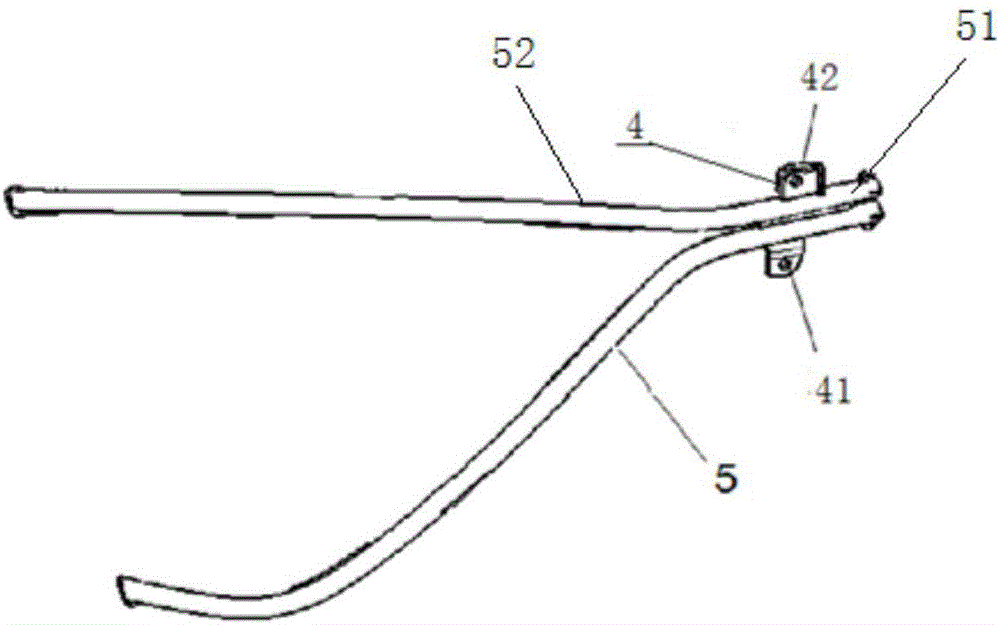

[0024] Such as figure 2 As shown, an anti-leakage structure of a light guide for a vehicle lamp includes: an LED light source 3 , a light guide 5 , a screw 8 , a fixing piece 4 , a light guide mounting bracket 6 and a light guide guard plate 7 . The light guide mounting bracket 6 is provided with a light guide fixing groove 61. The light guide guard plate 7 cooperates with the light guide mounting bracket 6 and covers the light guide fixing groove 61. The two are detachably connected together. The light guide guard plate 7 and the light guide mounting bracket 6 are integrated A cavity with front and rear openings is formed, the rear opening of the cavity wraps the LED light source 3, the light source incident end of the light guide is connected to the LED light source 3, and is fixed on the light guide mounting bracket 6, and the light guide is from the light source incident en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com