A test system and test method for the static clearance field of a rotating machine

A test method and technology of rotating machinery, applied in measuring devices, instruments, electrical devices, etc., can solve problems such as less research on measurement and animation display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

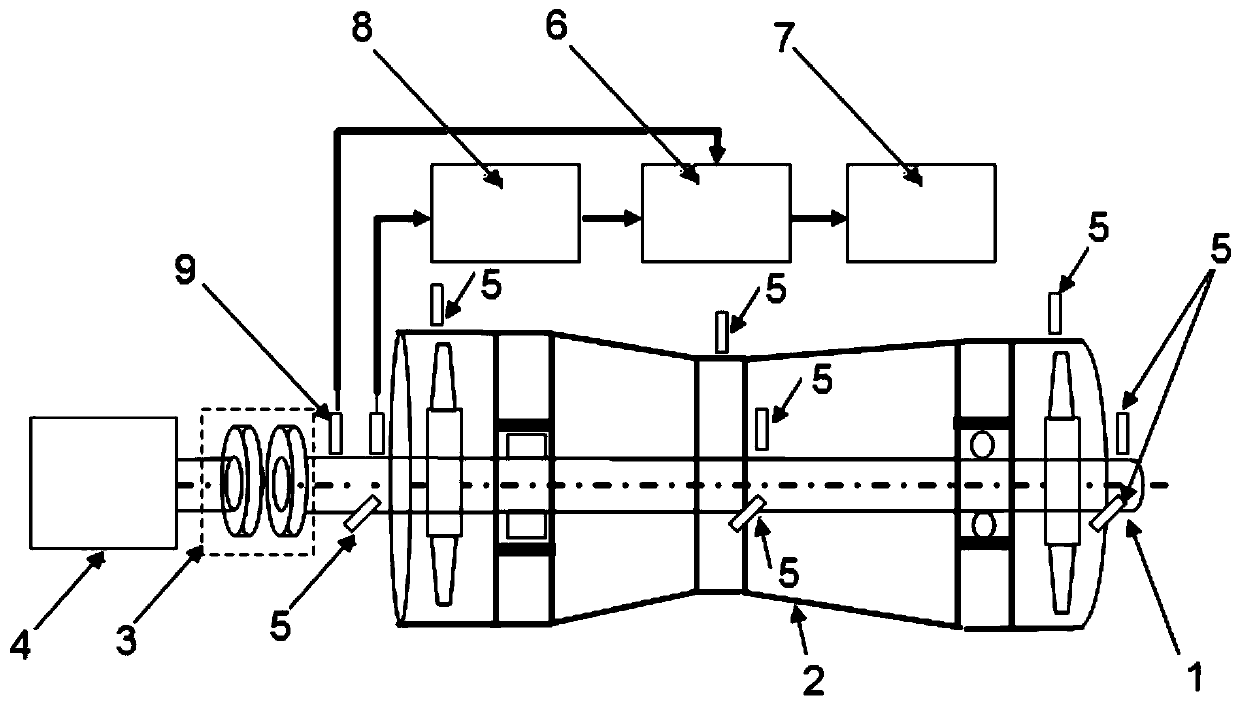

[0032] The rotary machine selected in this embodiment is an aero-engine rotor tester with casing. Such as figure 1 The test system for the rotary-static gap field of the rotating machine shown in the aeroengine rotor tester includes a rotor 1 and a stator 2; one end face of the shaft of the rotor 1 is connected to a motor 4 through a nylon rope coupling 3, and the motor 4 drives the rotor 1 to rotate. On the rotor 1 and the stator 2, several radial sections are selected as the test surfaces; an eddy current displacement sensor 5 is respectively installed horizontally and vertically outside the circumference of each test surface, and the eddy current displacement sensor 5 is fixed by a bracket. To obtain the horizontal and vertical displacements of the rotor 1 and stator 2 test surfaces respectively.

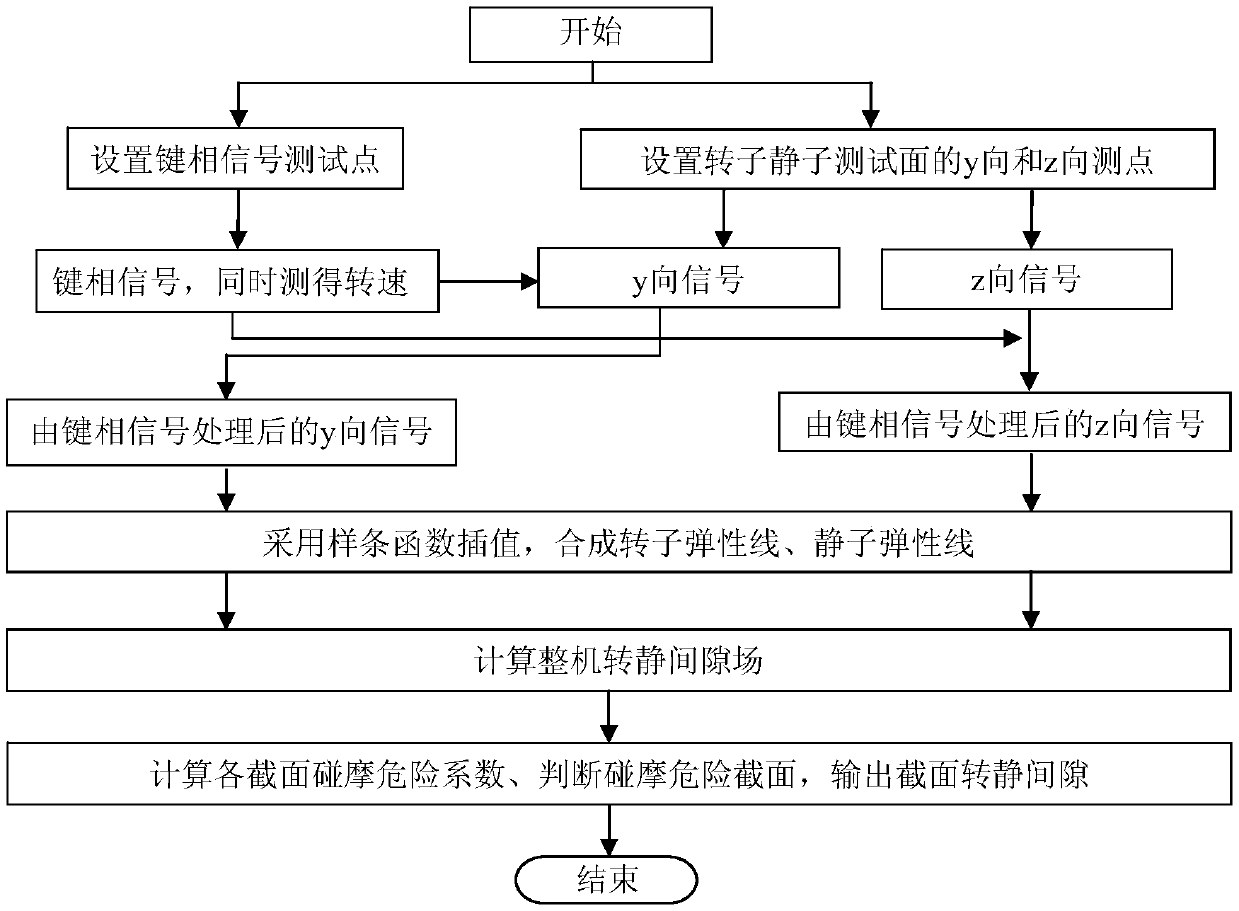

[0033] Set a key phase signal point at the key groove of the roto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com