A Dynamic Modeling Method for Suspended Liquid-Filled Storage Tank

A dynamic modeling and suspension technology, applied in the field of spacecraft dynamic modeling and analysis, can solve the problems of high generalized mass calculation value, dangerous flight status, large difference between normalized mode shape value and test value, etc. , to achieve good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

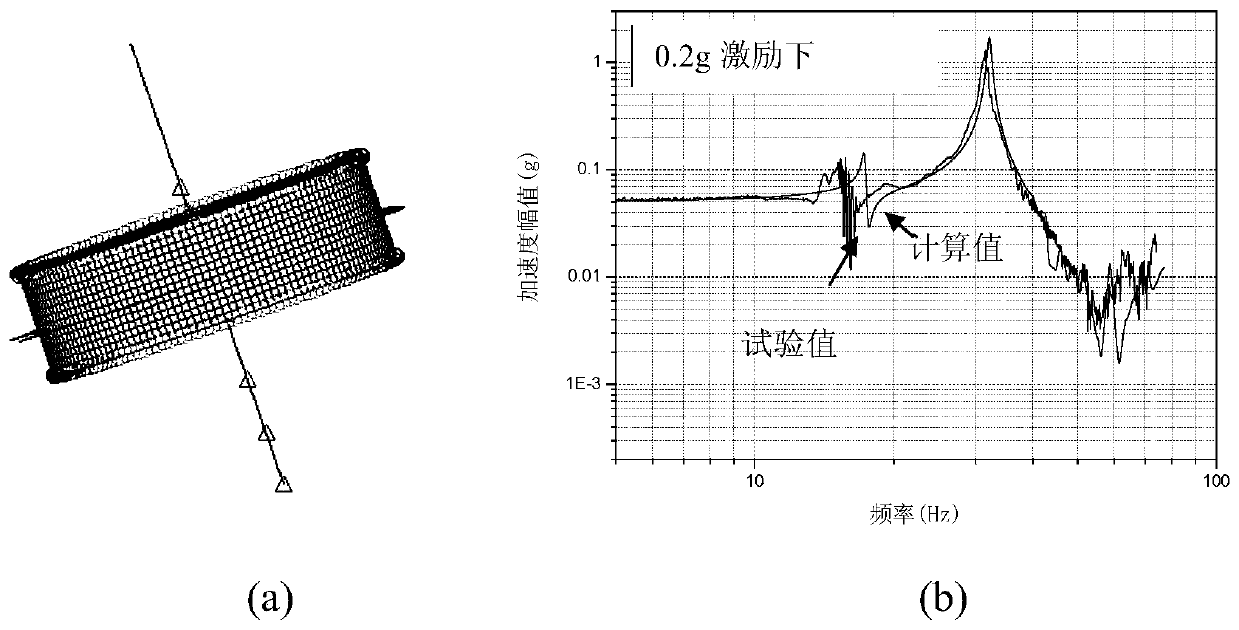

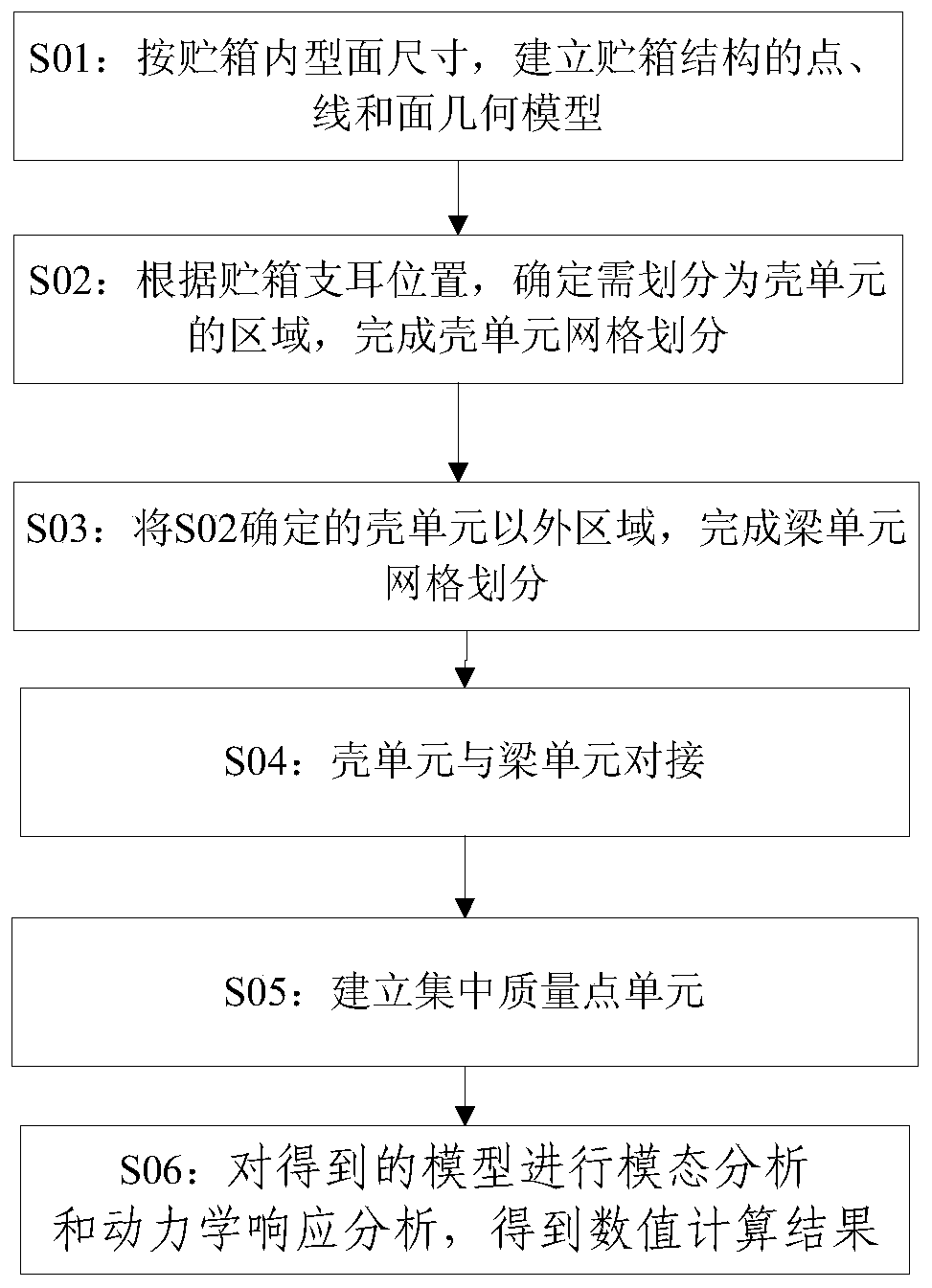

[0034] In order to obtain better modal and dynamic response prediction values, the present invention proposes a "shell + beam + lumped mass point unit" suspension liquid-filled storage tank modeling method, such as figure 1 shown, including the following steps:

[0035] S01: According to the size of the internal surface of the tank, establish the point, line and surface geometric model of the tank structure, the midpoint is located on the central axis of the tank, and the line is located on the central axis of the tank.

[0036] S02: Apply Saint-Venant's principle to divide the tank barrel section and tank lugs into shell elements within the H range above and below the circumference of the lugs to eliminate the influence of boundary effects and ensure a more reasonable connection stiffness simulation. H is not less than the radial length of the lug of the storage tank, generally 100mm. The support connecting the lug of the tank and the spacecraft is divided into shell element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com