A method for rapid preparation of thermoelectric devices

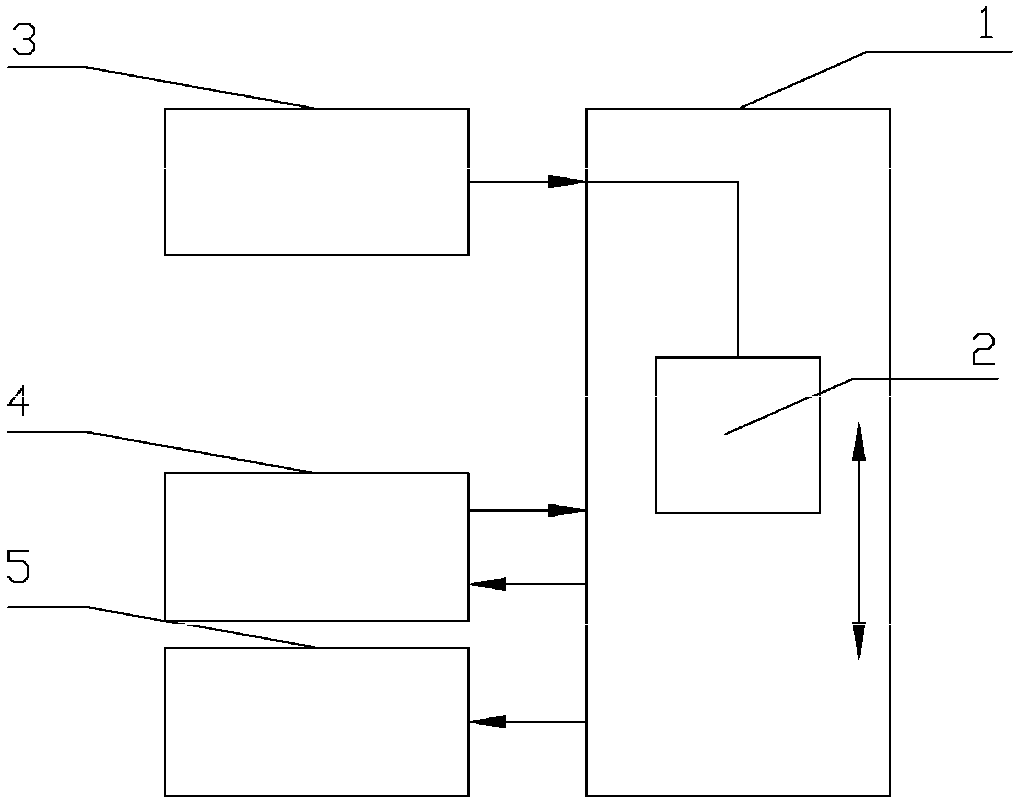

A thermoelectric device, fast technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric devices that only use the Peltier or Seebeck effect, etc., can solve the problems of low yield and low raw material utilization, and achieve high printing efficiency and regular structure , to overcome the effect of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083]A rapid preparation of p-type Bi 0.5 Sb 1.5 Te 3 n-type Bi 2 Te 2.8 Se 0.2 A method for a thermoelectric device, comprising the steps of:

[0084] 1) Prepare the raw materials and weigh the composition as Bi 0.5 Sb 1.5 Te 3 (p-type thermoelectric material) and Bi 2 Te 2.8 Se 0.2 (n-type thermoelectric material) thermoelectric material powder and 500 grams of electrode powder Cu powder, each raw material powder is dispersed in 300ml, 300ml and 220ml of water after passing through a 400-mesh sieve, and then placed in 3 different storage tanks As the ink for inkjet printing in the material tank, the ink in the material storage tank is transported to the inkjet printing nozzle under the action of pressure; and prepare a square Al with a thickness of 1mm and a side length of 30mm 2 o 3 Place and fix the ceramic plate on the printing substrate; pre-evacuate the forming cavity of the selective laser melting device for 5 minutes, then use Ar gas to backfill the cavit...

Embodiment 2

[0091] A method for rapidly preparing p-type SnTe / n-type SnSe thermoelectric devices, comprising the steps of:

[0092] 1) Prepare raw materials, weigh 500 grams each of thermoelectric material powder composed of SnTe (p-type thermoelectric material) and SnSe (n-type thermoelectric material) and electrode powder Ag powder, and pass through a 400-mesh sieve for each raw material powder, Disperse in 230ml, 250ml and 250ml of water respectively, and then place them in 3 different storage tanks as the ink for inkjet printing. The ink in the storage tanks is transported to the inkjet printing nozzle under pressure; the preparation thickness is 1mm Al 2 o 3 Place and fix the ceramic plate on the printing substrate; pre-evacuate the forming cavity of the selective laser melting device for 5 minutes, then use Ar gas to backfill the cavity to normal pressure, keep the water and oxygen content in the cavity below 100ppm, and the substrate is pre-evacuated Heat to 80°C and hold for 10 ...

Embodiment 3

[0099] A rapid preparation of p-CeFe 4 Sb 12 Binding n-type Co 4 Sb 12-x Te x (x=0~0.1) the method for thermoelectric device, comprises the steps:

[0100] 1) Prepare raw materials, including Al 2 o 3 Ceramic insulating substrate, Cu 50 Mo 50 Alloy electrode powder, p-type p-CeFe 4 Sb 12 Thermoelectric compound powder and n-type Co 4 Sb 12-x Te x (x=0~0.1) thermoelectric compound powder, wherein the particle size of each powder raw material is below 50 μm, and respectively dispersed in water to make a suspension for inkjet printing in the subsequent step, the mass percentage of the suspension is equal to 30%;

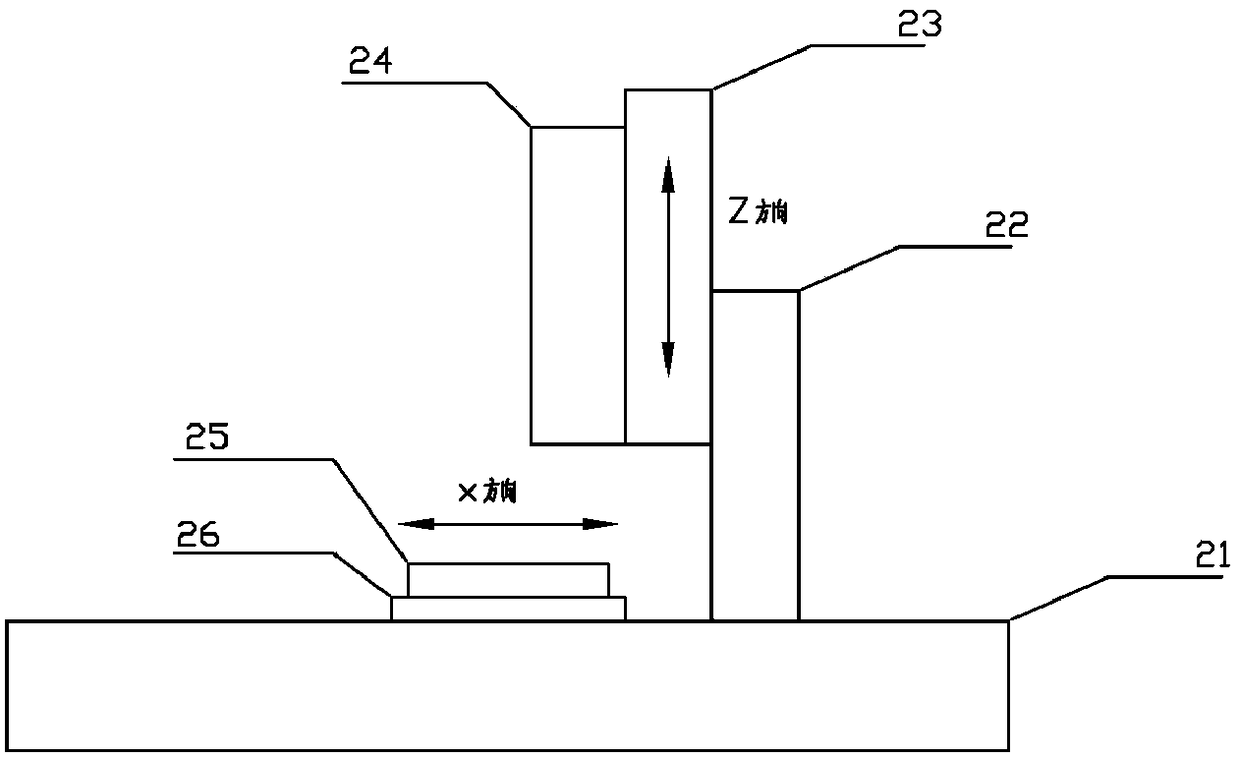

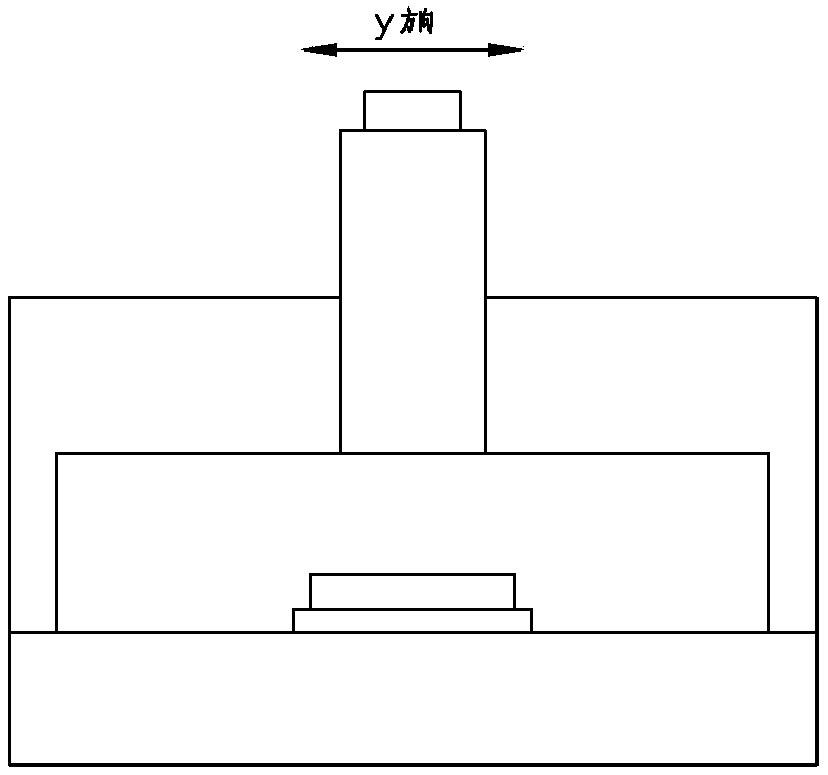

[0101] 2) According to the required electrode pattern and thickness, the electrode powder suspension is inkjet-printed on the insulating substrate (1) by using a selective laser melting process to obtain the insulating substrate printed with the electrode layer (1);

[0102] 3) According to the designed device thermoelectric arm size and distribution, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com