A method for the ultra-fast preparation of thermoelectric devices in one step from simple powders as starting materials

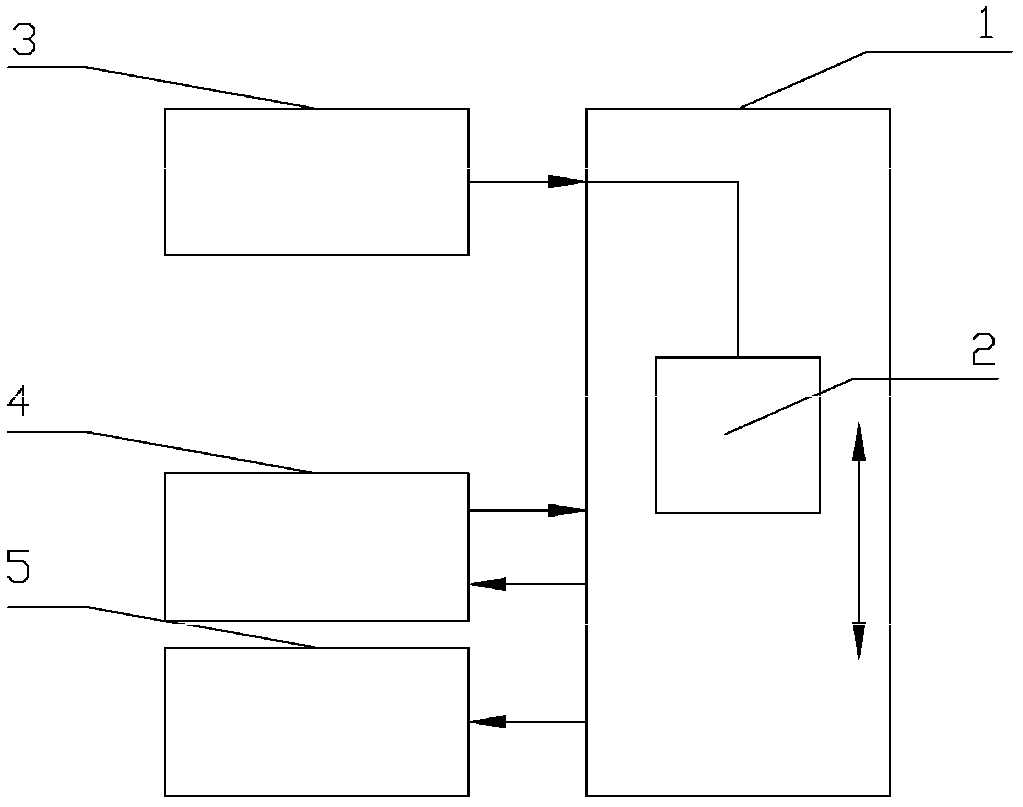

An ultra-fast technology for thermoelectric devices, applied in the field of rapid preparation of thermoelectric devices, can solve the problems of low yield and low utilization rate of raw materials, achieve high printing efficiency, overcome low utilization rate of raw materials, and shorten the synthesis time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

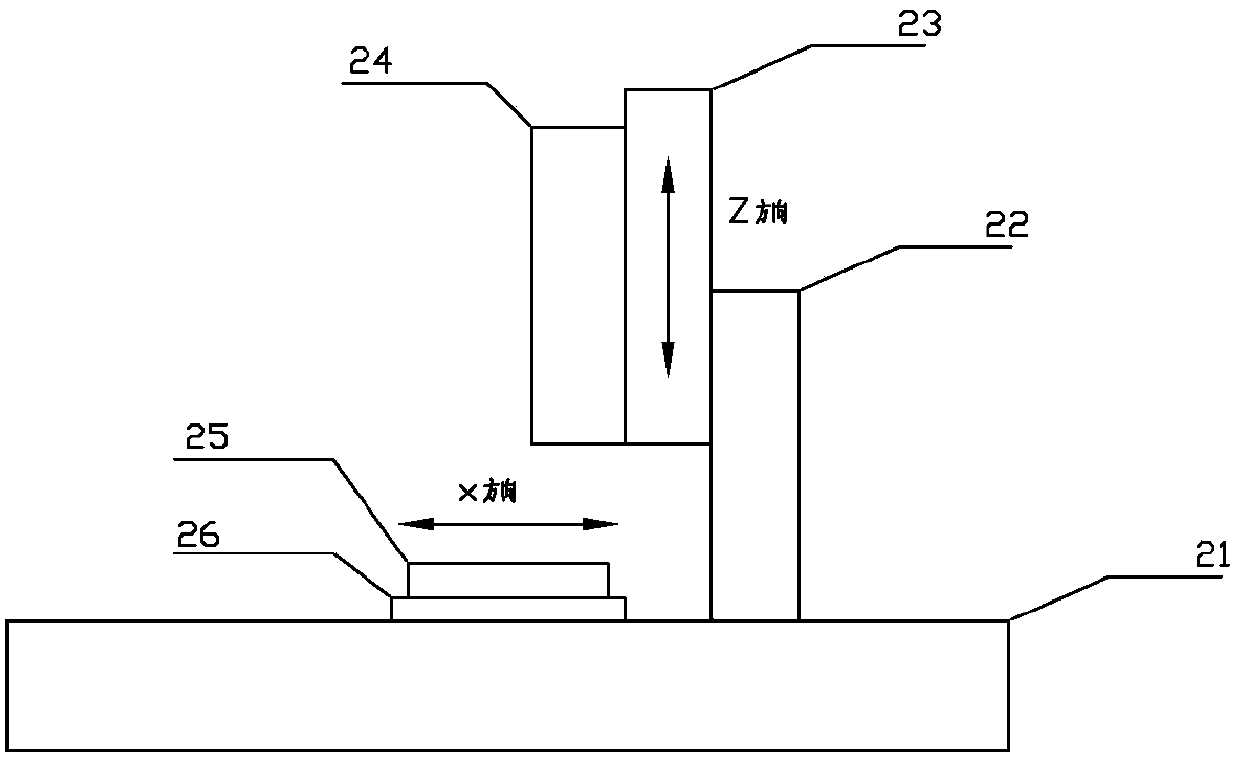

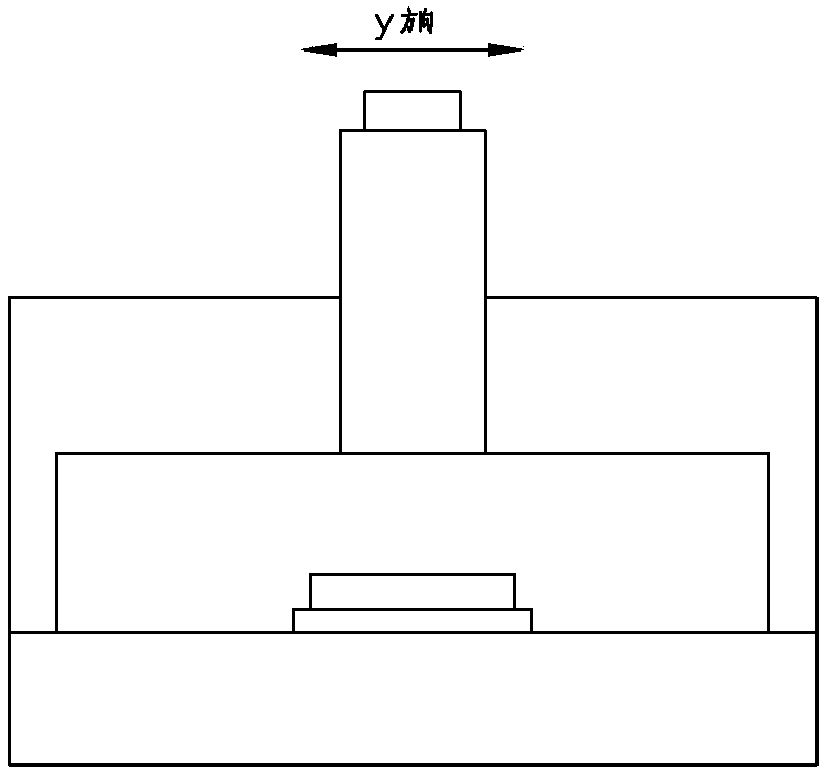

Method used

Image

Examples

Embodiment 1

[0096] One-step ultrafast preparation of n-type Bi from simple powder as starting material using this device 2 Te 2.7 Se 0.3 , p-type Bi 0.5 Sb 1.5 Te 3 A method for a thermoelectric device, comprising the steps of:

[0097] 1) Preparation of raw materials: according to the p-type thermoelectric compound Bi 0.5 Sb 1.5 Te 3 The stoichiometric ratio of each element in the prepared elemental powder Bi powder, Sb powder, Te powder (both 300 mesh, 4N) total 1Kg, as in the ball mill tank filled with Ar gas, carry out 2h sufficient mixing on the horizontal ball mill, Obtain the raw material powder of the p-type thermoelectric compound; at the same time, according to the n-type thermoelectric compound Bi 2 The stoichiometric ratio of each element in Te2.7Se0.3 prepares a total of 1Kg of elemental powder Bi powder, Te powder, and Se powder (both 300 mesh, 4N). As for the ball mill tank filled with Ar gas, it is carried out on a horizontal ball mill Fully mixed for 2 hours to o...

Embodiment 2

[0106]The method for preparing n-type SnSe and p-type SnTe thermoelectric devices ultra-fast in one step using the device as a starting material comprises the following steps:

[0107] 1) Preparation of raw materials: According to the stoichiometric ratio of each element in the p-type thermoelectric compound SnTe, prepare a total of 1Kg of elemental powder Sb powder and Te powder (both 300 mesh, 4N). As for the ball mill tank filled with Ar gas, in the horizontal Fully mix on the ball mill for 2 hours to obtain the raw material powder of the p-type thermoelectric compound; at the same time, prepare the elemental powder Sn powder and Se powder (both 300 mesh, 4N) according to the stoichiometric ratio of each element in the n-type thermoelectric compound SnSe , as for the ball mill tank filled with Ar gas, fully mix it on a horizontal ball mill for 2h to obtain the raw material powder of n-type thermoelectric compound; and prepare electrode material Cu powder (300 mesh) and insul...

Embodiment 3

[0116] One-step ultrafast preparation of p-CeFe from simple powder as starting material 4 Sb 12 Binding n-type Co 4 Sb 12-x Te x (x=0~0.1) the method for thermoelectric device, comprises the steps:

[0117] 1) Prepare raw materials: according to p-type CeFe 4 Sb 12 The stoichiometric ratio of each element in the thermoelectric compound is prepared for each elemental powder, and fully mixed under the protection of an inert gas to obtain the raw material powder of the p-type thermoelectric compound; at the same time, according to the n-type Co 4 Sb 12- x Te x (x=0~0.1) The stoichiometric ratio of each element in the thermoelectric compound Prepare the elemental powders, and fully mix them under the protection of an inert gas to obtain the raw material powder of the n-type thermoelectric compound; and prepare Cu 50 Mo 50 Alloy electrode powder and insulating ceramic substrate;

[0118] Among them, the particle size of the electrode powder, the raw material powder of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com