Weeding composition

A herbicidal composition and a technology for the composition, applied in the field of pesticides, can solve problems such as expanding the herbicidal spectrum, and achieve the effect of expanding the herbicidal spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: Indoor toxicity assay

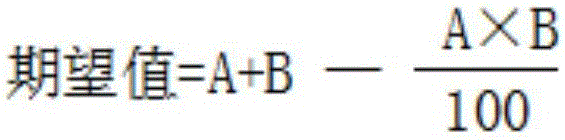

[0045] Colby's equation is used to determine the expected herbicidal action of a mixture (Colby, S.R. Weeds 1967, 15, 20-22. Calculation of the synergistic and antagonistic response of herbicide combinations):

[0046] The following equation was used to calculate the expected activity of a mixture containing the two active ingredients A and B:

[0047]

[0048] In the formula:

[0049] A = efficacy of active ingredient A at the same concentration observed for the mixture;

[0050] B = efficacy of active ingredient B at the same concentration observed for the mixture.

[0051] When the actual observed activity of the mixture at the concentration used is greater than expected, the mixture appears to have an unexpected synergistic effect on the target weed.

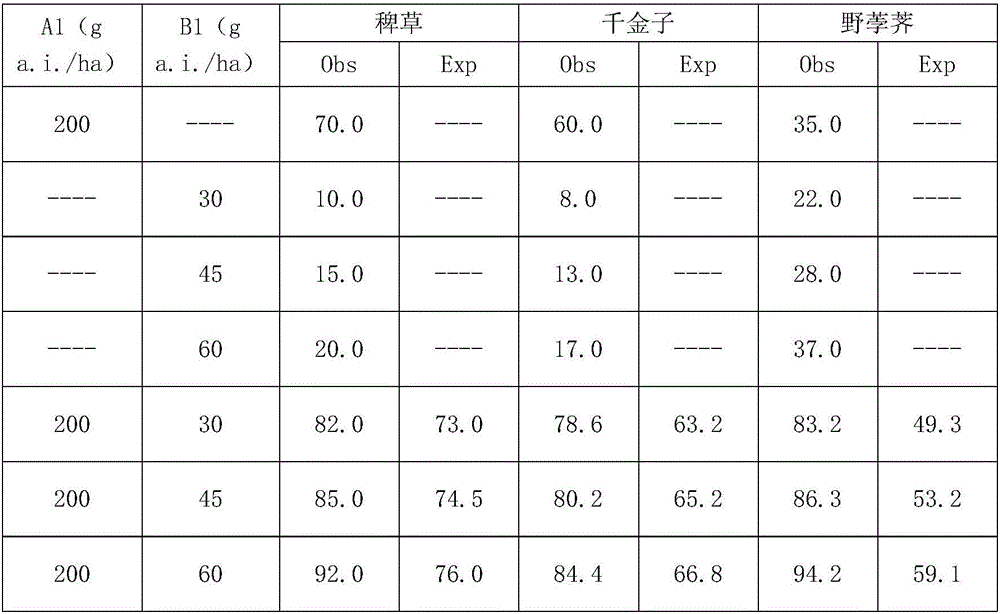

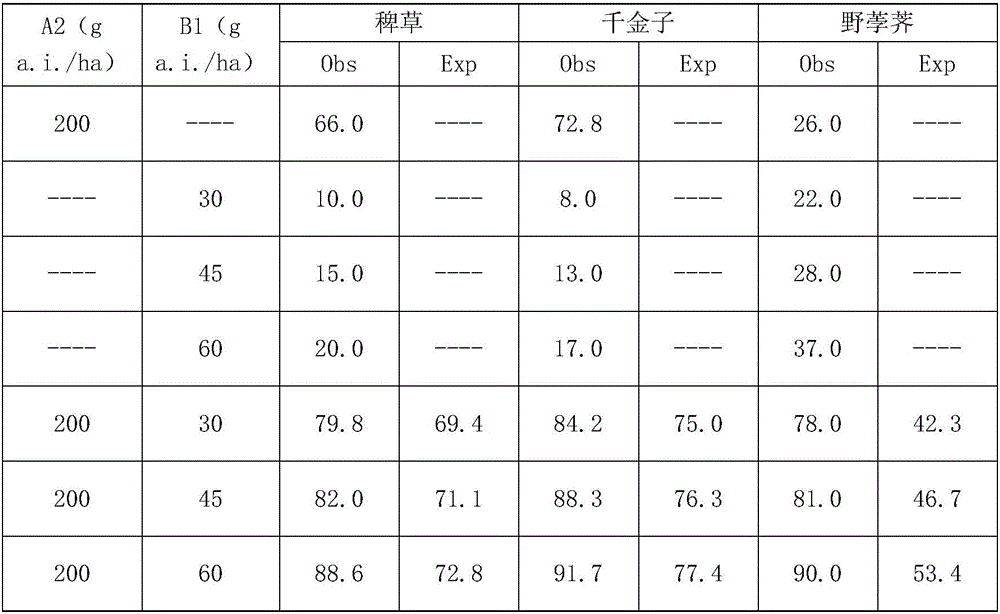

[0052] Toxicity determination of quinclomid, cyhalofop-ethyl, sulfonylurea herbicides and their combinations on barnyardgrass (Echinochloacrusgalli), daughter-in-law (Lept...

Embodiment 2

[0104] Example 2: 66% quinclozone·cyhalofop-ethyl·bensulfuron-methyl water-dispersible granule.

[0105] The following substances are all in weight ratio: quinclomidone 30%, cyhalofop-methyl 30%, bensulfuron-methyl 6%, fatty acid ester sulfate 6%, polycarboxylates 4%, corn flour 8%, Sodium lignosulfonate 9%, diatomaceous earth to 100%; put the above materials together into the conical mixer and mix evenly, and then pulverize through the jet mill, and the pulverized materials are then mixed through the conical mixer, and the mixed The fineness of the material is 98% and passes through a 600-mesh standard sieve, and is added to a kneader to knead into a plastic material. Finally, the material is put into an extrusion granulator to extrude and granulate. After granulation, it is dried and sieved to obtain 66 % quinclomidone · cyhalofop-methyl · bensulfuron-methyl water dispersible granules.

Embodiment 3

[0106] Example 3: 46% quinclozone·cyhalofop-ethyl·bensulfuron-methyl water-dispersible granule.

[0107] The following substances are all in weight ratio: quinclodone 20%, cyhalofop-methyl 20%, bensulfuron-methyl 6%, fatty acid ester sulfate 6%, polycarboxylates 4%, corn flour 8%, Sodium lignosulfonate 9%, diatomaceous earth to 100%; put the above materials together into the conical mixer and mix evenly, and then pulverize through the jet mill, and the pulverized materials are then mixed through the conical mixer, and the mixed The fineness of the material is 98%, which passes through a 600-mesh standard sieve, and is added to a kneader to knead into a plastic material. Finally, the material is put into an extrusion granulator to extrude and granulate. After granulation, it is dried and sieved to obtain 46 % quinclomidone · cyhalofop-methyl · bensulfuron-methyl water dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com