Positioning mounting seat for piston oiling, rotating positioning mounting seat, piston oiling method

A technology of positioning installation and mounting seat, which is applied to the device and coating of the surface coating liquid, which can solve the problems of unstable grip, low work efficiency, and labor consumption, so as to save oiling time and improve oiling efficiency. Effect, solve the effect of unstable grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

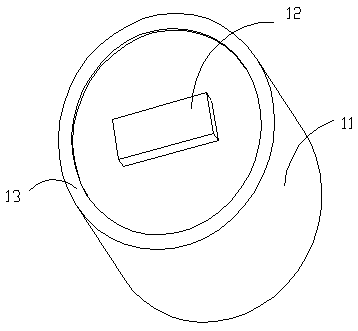

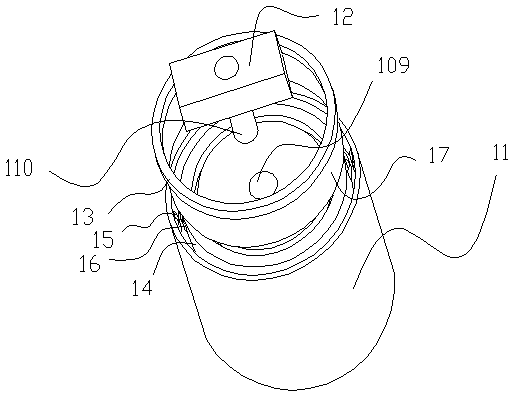

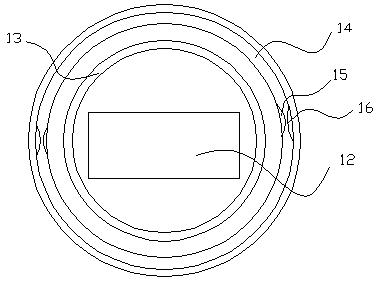

[0027] Such as figure 1 , 2 , 3, the present embodiment discloses a positioning mounting seat for piston oiling, including a bottom mounting seat 11 and an upper mounting seat 12. The upper mounting base 12 is arranged above the bottom mounting base 11 and is detachably connected with the upper mounting base 12 . The edge of the top of the bottom mounting seat 11 is provided with a protrusion 13 that is adapted to the shape of the piston stop to be oiled. The distance between the two ends of the upper mounting seat 12 in the length direction is equal to or slightly smaller than the distance between the two pin-hole seats in the piston to be oiled.

[0028] In this embodiment, the piston to be oiled is placed on the positioning mounting seat, so that the stop of the piston to be oiled is limited on the protrusion 13 at the top edge of the positioning mounting seat, so that the upper mounting seat 12 of the positioning mounting seat is limited. Located between the two pin-hol...

Embodiment 2

[0039] Such as figure 1 , 2 , Shown in 3, a kind of piston oiling is used rotation positioning mounting seat, comprises bottom mounting seat 11, upper mounting seat 12, motor. The motor is arranged under the bottom mounting base 11, and the bottom mounting base 11 is connected with the output shaft of the motor. The upper mounting base 12 is arranged above the bottom mounting base 11 and is detachably connected with the upper mounting base 12 . The edge of the top of the bottom mounting seat 11 is provided with a protrusion 13 that is adapted to the shape of the piston stop to be oiled. The distance between the two ends of the length direction of the upper mounting seat 12 is equal to or slightly smaller than the distance between the two pin-hole seats in the piston to be oiled.

[0040] In some embodiments: the bottom of the bottom mounting seat is provided with a mounting groove, and a rubber sleeve is sleeved in the mounting groove, and the output shaft of the motor is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com