Stripper plate structure capable of punching several tens of thousands of products and method thereof

A technology for stripping plates and products, which is applied in the direction of manufacturing tools, metal processing equipment, stripping devices, etc., can solve the problems of difficult alignment gaps and low life of stamping die structures, and achieve simple structure, reduced processing life, and reduced thickness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

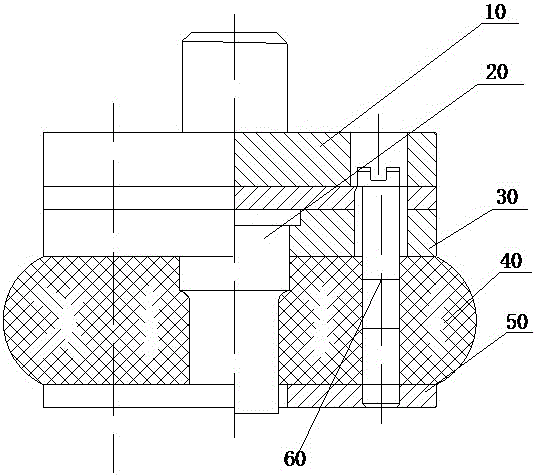

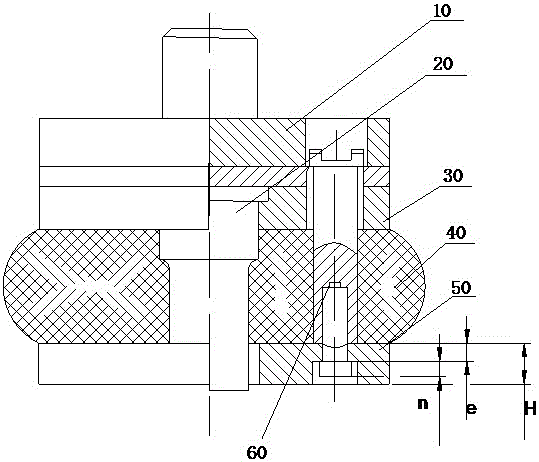

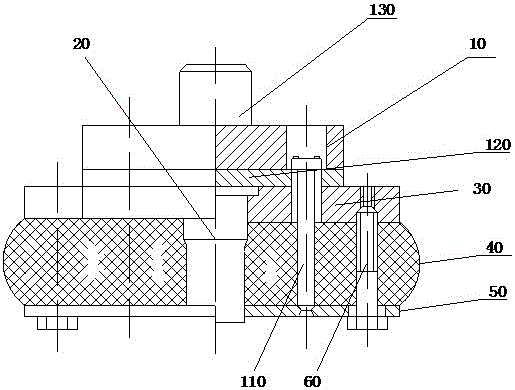

[0015] Such as Figure 3-4 As shown, a stripping plate structure capable of punching tens of thousands of products includes an upper template 10, a punch fixing plate 30, a rubber pad 40 and a stripping plate 50 arranged sequentially from top to bottom. The upper template 10 There is a guide post 110 running through the stripping plate, and a punch 20 is provided in the middle of the upper template 10. The punch fixing plate 30, the rubber pad 40 and the middle of the stripping plate 50 have a through hole for the punch to pass through, and the punch is fixed. Both sides of the plate, the rubber pad and the stripper plate are provided with a flange portion 510 protruding from the outer side of the upper formwork, and the flange portion is provided with a bolt hole for the bolt to pass through. During the trial punching operation, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com