Pressure-pad-force adjustable drawing die structure and usage method thereof

An adjustable blank-holding force technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of capital waste, blank-holding force cannot be adjusted in size, deep-drawing waste products, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

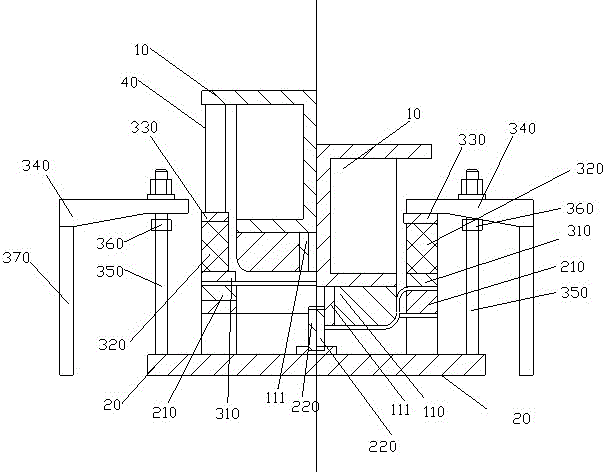

[0020] Such as figure 1 As shown, a drawing die structure with adjustable blank-holding force in this embodiment includes a stamping die set on a single-action press, the stamping die includes an upper die base 10 and a lower die base 20, and a drawing die 210 is set On the lower die base 20 , the drawing punch 120 is set on the upper die base 10 , and the upper edge of the upper die base 10 is set above the drawing die 210 .

[0021] Between the upper edge of the upper die base 10 and the drawing die 210, there is also a blank holder 310 arranged sequentially on the upper surface of the product to be processed. A rubber 320 is provided on the blank holder 310, and a rubber 320 is provided above the rubber. The rubber pressing plate 330.

[0022] In this embodiment, during the test, two or more ejector pins 40 for testing are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com