Tea caddy forming tool

A technology of forming tooling and tea cans, which is applied in the field of machinery, can solve the problems of high price and insufficient output, and achieve the effects of simple mechanical tooling, convenient forming and production, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

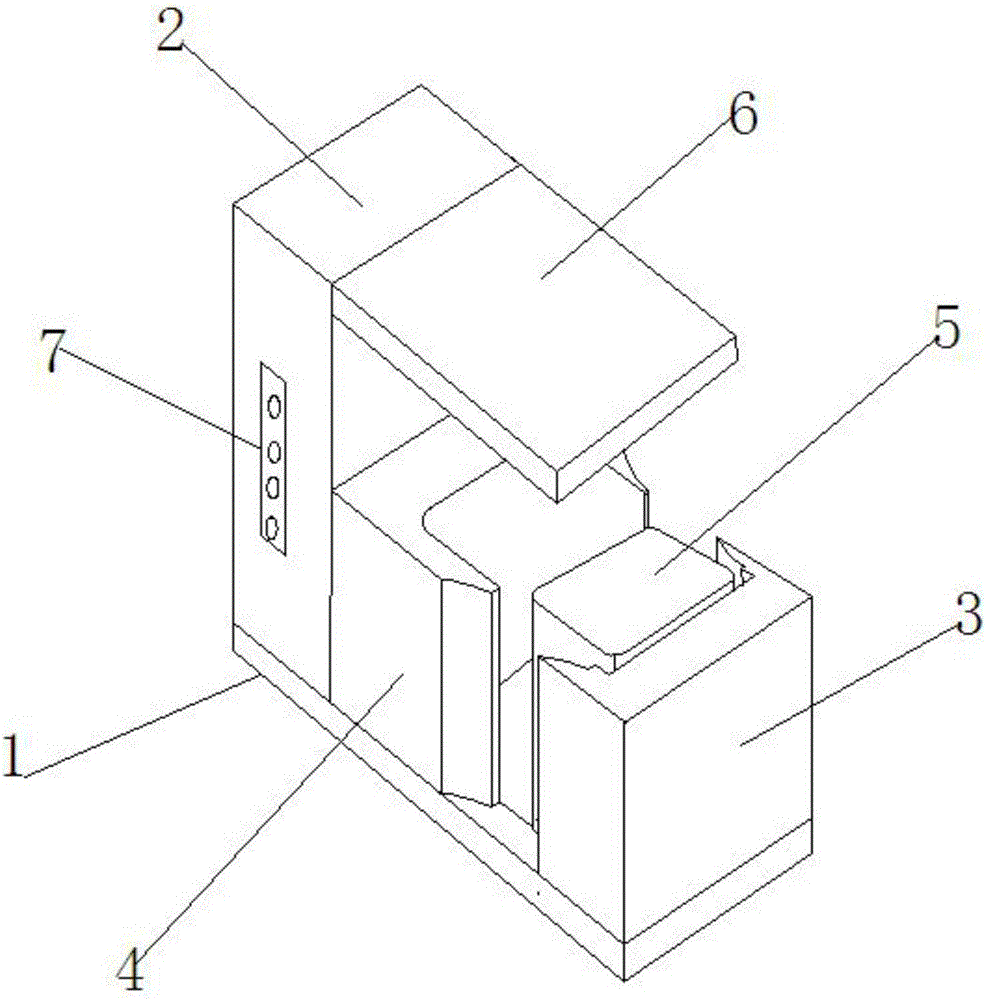

[0014] Such as figure 1 As shown, the present invention discloses a tea can forming tooling, comprising a slide rail 1, one end of the slide rail 1 is fixedly provided with a fixing member 3, and the other end of the slide rail 1 is provided with a power device 2, on which the power device 2 A movable part 4 is provided, and the movable part 4 is located between the power device 2 and the fixed part 3, and the movable part 4 moves along the slide rail 1, and the fixed part 3 and the movable part 4 have grooves at positions facing each other. When the movable part slides on the slide rail 1 and comes into contact with the fixed part 3, the edge interfaces of the two are meshed, and the groove of the fixed part 3 and the movable part 4 forms a mold gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap