Lamp heat plate welding equipment

A technology of hot plate welding and equipment, which is applied in the direction of welding equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of large equipment structure, large occupied area, inconvenient moving, etc., and achieve high production efficiency and low occupied area. Small and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

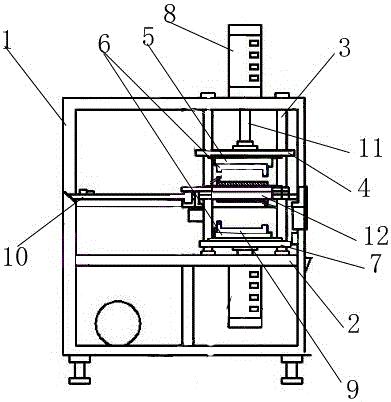

[0012] like figure 1 As shown, a lamp hot plate welding equipment includes an equipment body 1, the equipment body is provided with a support plate 2 laterally, and a set of welding ribs 3 are fixedly installed between the upper left of the equipment body and the support plate; The upper sleeve is provided with an upper clamp 4 and a lower clamp 7, the lower end of the upper clamp 4 is installed with an upper pressing table 5, and the upper end is connected with a cylinder 8 arranged outside the upper end of the equipment body; The cylinder in the lower end of the equipment body is connected; the guide rail 10 is installed laterally in the equipment body between the upper clamp and the lower clamp, and the movable support plate 12 for placing the lamps is installed on the guide rail; A heating plate is arranged between the lower clamp and the lower pressing table. One cylinder is connected with the upper clamp through the piston rod 11, and the other cylinder is connected wit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap