A laser-driven hydraulic bulging plate riveting method and structure

A hydraulic bulging and laser-driven technology, which is applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of production efficiency and reliability, complex mechanism, complex special device, small lateral deformation, etc., to achieve Large production flexibility, high production reliability, and the effect of reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

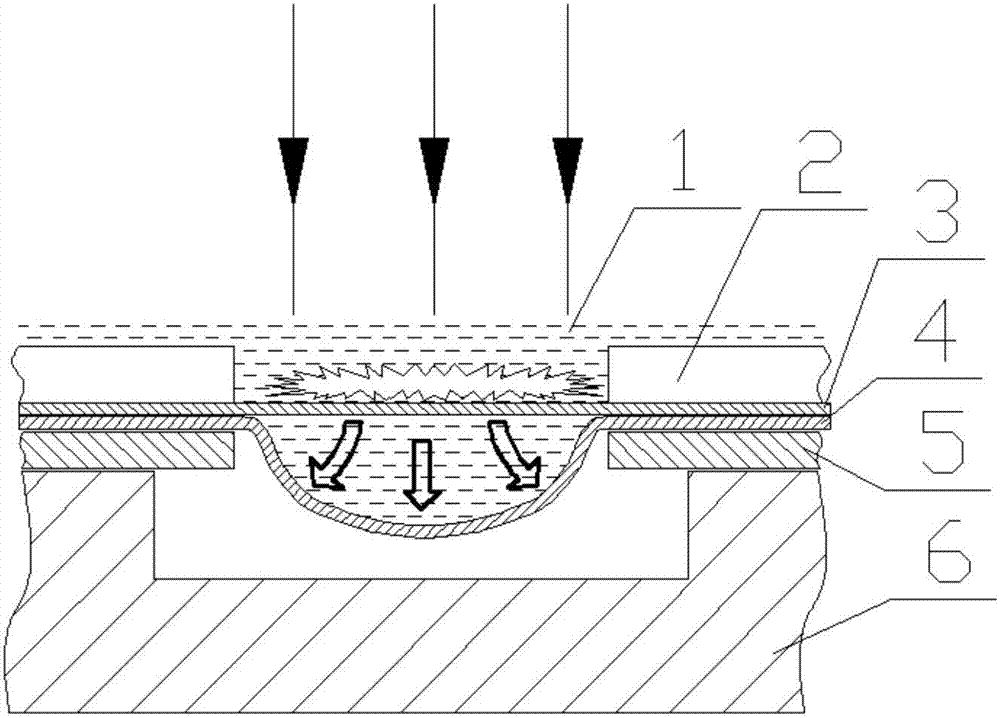

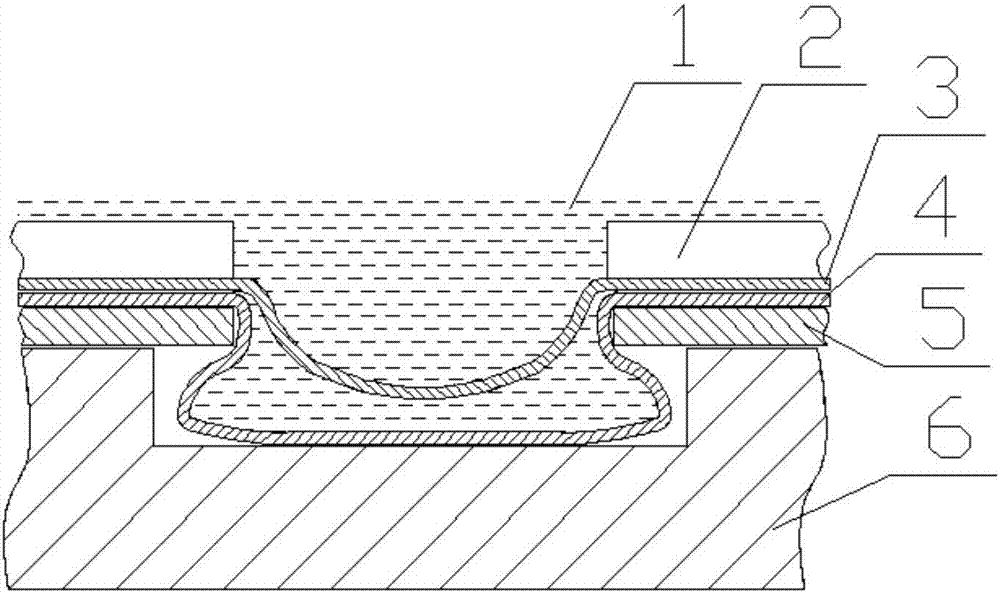

[0044] Embodiment 1: A laser-driven hydraulic bulging plate riveting method mainly includes the following steps:

[0045] (a) placing the lower sheet material 5 and the middle layer sheet material 4 with a bulge on the forming mold 6 in sequence, and the center of the bulge structure of the middle layer sheet material 4 is aligned with the center of the riveted position of the lower layer sheet material 5;

[0046] (b) Inject transparent liquid 1 to fill the bulging structure of the middle layer plate 4;

[0047] (c) Place the upper plate 3 above the middle plate 4, and then use the pressing device 2 to compress each layer of plate;

[0048] (d) In order to enhance the laser impact effect, inject transparent liquid 1 on the upper part of the upper plate 3, the depth is not greater than 5mm;

[0049] (d) if figure 1 As shown, the surface of the upper plate 3 is irradiated with a pulsed laser, and explosive plasma is formed on the surface of the upper plate 3. The explosive pl...

Embodiment 2

[0056] Embodiment 2: A laser-driven hydraulic bulging plate riveting method mainly includes the following steps:

[0057] (a) placing multiple layers of bulging middle-layer sheets 4 on top of the split-type lower-layer sheet 5 in sequence, and aligning the center of the bulging structure of the middle-layer sheet 4 with the geometric center of the through hole of the lower-layer sheet 5;

[0058] (b) Inject transparent liquid 1 to fill the bulging structure of the middle layer plate 4;

[0059] (c) Place the upper plate 3 above the middle plate 4, and then use the pressing device 2 to compress each layer of plate;

[0060] (d) In order to enhance the laser impact effect, inject transparent liquid 1 on the upper part of the upper plate 3, the depth is not greater than 5mm;

[0061] (d) Using pulsed laser to irradiate the surface of the upper plate 3, forming explosive plasma on the surface of the upper plate 3, the explosive plasma impacts the surface of the upper plate 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com