Novel hydraulic machine stand column structure

A hydraulic machine and column technology, applied in the field of hydraulic machine column structure, can solve the problems of body instability, complex design structure, and high manufacturing difficulty, and achieve the effects of reducing and absorbing body vibration, stable and reliable work, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

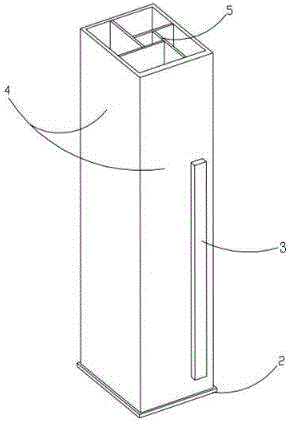

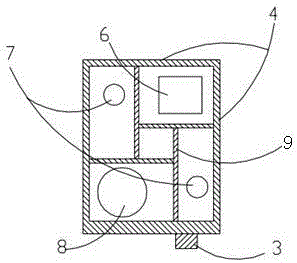

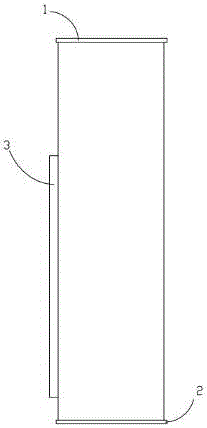

[0016] Such as Figure 1~4 As shown, a new hydraulic machine column structure includes an upper panel 1, a lower panel 2, a column body surrounded by wall panels 4 and a slider guide support plate 3, and the upper panel 1 and the lower panel 2 are respectively fixedly connected to the column body At the upper and lower ends of the upper and lower ends, the slider guide rail support plate 3 is fixedly connected to the side of the main body of the column, and a rib structure 5 is arranged inside the main body of the column. 9. Five square cavities are formed. Positioning holes 7, tie rod holes 8 and wiring holes 6 are arranged in the cavities. The main body of the column, the upper panel 1, the lower panel 2, the slider guide rail support plate 3 and the rib structure 5 are welded fixed connection. The rib structure 5 is fixed by four rectangular steel plates; the rib structure 5 is fixed to the inner side of the column wall plate 4, the structure is simple, and the manufacture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com