02-type duck tongue corrugated carton packaging machine

A corrugated box and duck tongue corrugated technology, applied in the field of product packing equipment, can solve the problems of complex structure, increased production time consumption, increased maintenance difficulty, etc., and achieve the effect of increasing folding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

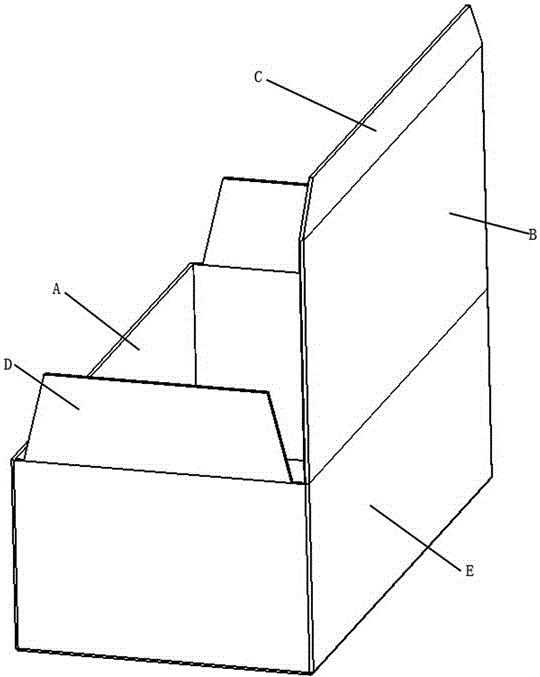

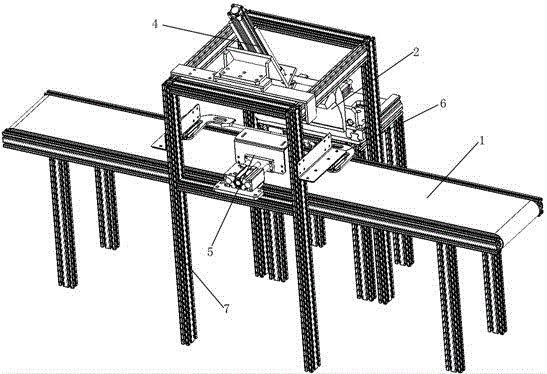

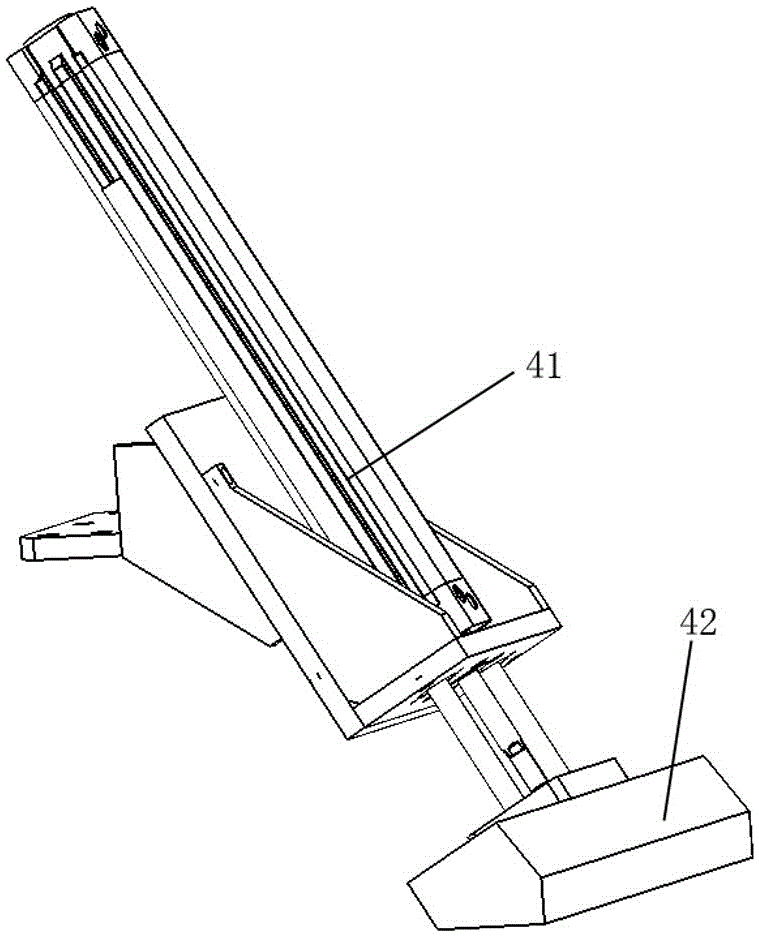

[0025] Such as Figure 1-7 As shown, a type 02 corrugated carton packaging machine with duck tongue includes a corrugated carton conveyor belt. 2. A strip-shaped groove 3 is provided along the inner end surface below, the width of the strip-shaped groove 3 is greater than the thickness of the side wall A of the corrugated box, and the top surface of the strip-shaped groove 3 is located above the side wall A of the corrugated box. The inner end face of the duck tongue guide plate 2 is provided with a pressing device 4 that moves up and down toward the upper side.

[0026] Further, a telescopic compression rod 5 is installed under the pressing device 4, and the telescopic compression rod 5 performs telescopic movement toward the duck tongue guide plate 2 above the corrugated box.

[0027] Further, the outer end surface of the duck tongue guide plate 2 is equipped with a cylinder 21 power drive device.

[0028] Further, a group of rotary beating plates 6 are arranged on both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com