Pallet fork bracket assembly for engineering machine

A technology of construction machinery and brackets, which is applied in the direction of lifting devices, etc., can solve the problems of driver safety accidents, easy cracking of L-shaped hook plates, and shaking of forks, so as to achieve high safety, eliminate cracking structures, and prevent forks shaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

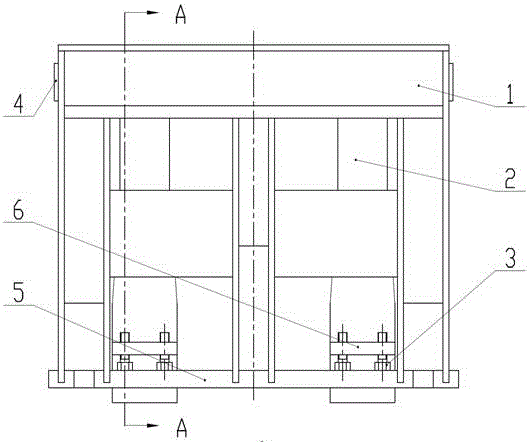

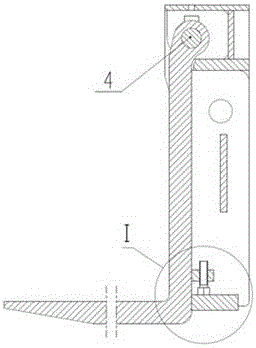

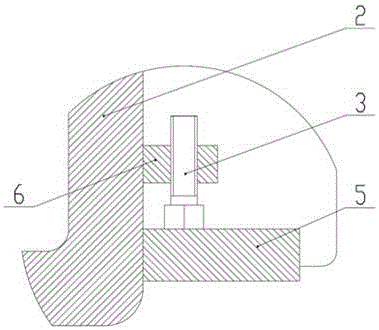

[0047] Such as figure 1 , figure 2 and Figure 13 As shown, a kind of fork bracket assembly for construction machinery of the present invention comprises a bracket 1, a fork 2, and a bracket bottom plate 5 welded on the lower part of the bracket 1; A pin 4 is connected, and the lower part of the fork 2 is provided with a mounting plate 6. The mounting plate 6 is located above the bracket bottom plate 5. Fork 2 position. The implementation of the mounting plate 6 shown in the figure here is a straight plate, which has a simple structure and high reliability, and avoids the defect that the L-shaped hook plate is difficult to eliminate the gap and is easy to break.

[0048] The specific embodiment of the limiting device of the present invention is to use bolts 3 for limiting. And each pallet fork 2 can be provided with a plurality of such limiting devices for pre-tighte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com