A kind of method of low temperature plasma modification catalyst carrier

A low-temperature plasma, catalyst carrier technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can achieve the effect of improving the activity or stability of the acetylene hydrochlorination catalyst, being environmentally friendly, and having a simple modification process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

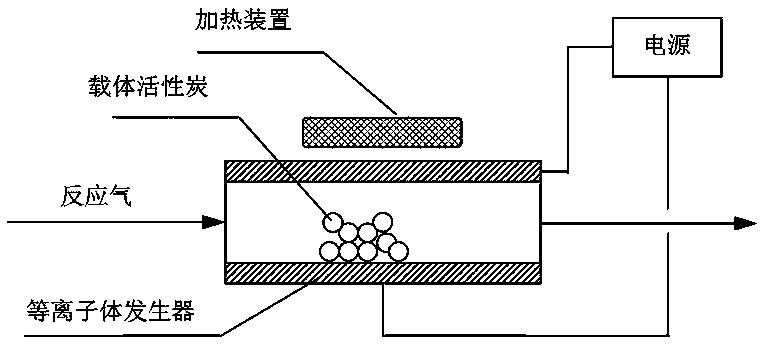

[0017] Refer to attached figure 1 , including a power supply, a plasma generator, and a device composed of a reaction gas in sequence. The plasma generator can be provided with a heating device; the carrier activated carbon is placed in the plasma generator, the reaction gas is passed through, and the plasma generator is turned on.

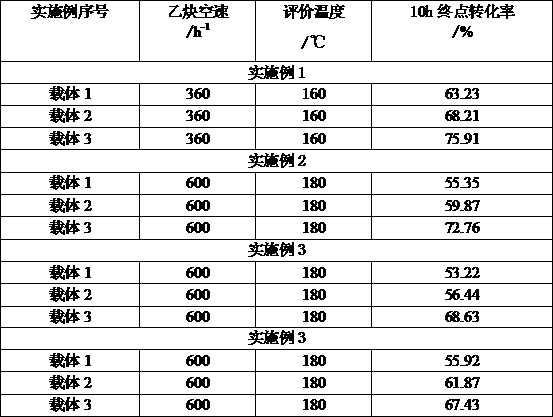

[0018] Recipe: Dissolve 0.82g of mercuric chloride in 20ml of hot water, and add 10g of the following carrier. Carrier 1: Untreated dry coal-based carbon; Carrier 2: Soak in 2M / L hydrochloric acid for 8 hours, wash with deionized water until neutral, and dry at 120°C for 8 hours; Carrier 3: Put dry activated carbon into a plasma reactor, and the reaction gas is Chlorine gas, reaction temperature 45°C, discharge power per unit volume 2.9W / cm 3 , the reaction time is 1min. Nitrogen was used to replace the remaining reaction gas.

Embodiment 2

[0020] The difference from Example 1 is that the formula: 0.1046g of chloroauric acid is dissolved in 20ml of water, and 10g of the following carrier is added. Carrier 1: Untreated dried coconut shell carbon; Carrier 2: Soak in 2M / L nitric acid for 8 hours, wash with deionized water until neutral, and dry at 120°C for 8 hours; Carrier 3: Put dry activated carbon into a plasma reactor, and the reaction gas is Nitrogen, reaction temperature 60°C, discharge power per unit volume 5W / cm 3 , The reaction time is 0.5min. Nitrogen was used to replace the remaining reaction gas.

Embodiment 3

[0022] The difference with Examples 1 and 2 is that the formula: 0.1046g of chloroauric acid is dissolved in 20ml of water, and 10g of the following carriers are added. Carrier 1: Untreated dry wood charcoal; Carrier 2: Soak in 2M / L sulfuric acid for 8 hours, wash with deionized water until neutral, and dry at 120°C for 8 hours; Carrier 3: Put dry activated carbon into a plasma reactor, and the reaction gas is sulfur dioxide , the reaction temperature is 80°C, and the discharge power per unit volume is 6W / cm 3 , The reaction time is 10min. Nitrogen was used to replace the remaining reaction gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com