Preparation method of light, thermal insulation and flame-retardant external wall decorative sheet

A technology for exterior wall decoration and decorative panels, which is applied to buildings, building structures, floors, etc., can solve problems such as loss of decorative panel decoration and flame retardant effect, damage to flame retardant exterior wall decorative panels, and threats to household safety. Enhanced thermal and sound insulation, light weight, enhanced safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

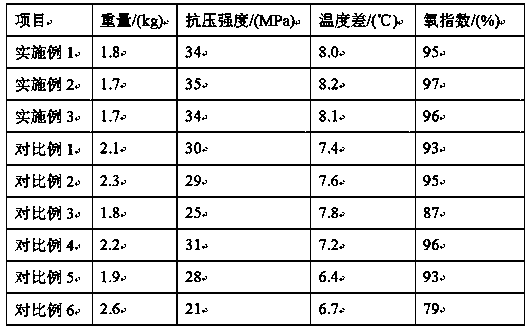

Examples

Embodiment 1

[0022] A method for preparing a light-weight thermal insulation and flame-retardant exterior wall decorative board, comprising the following steps:

[0023] (1) Kaolin modification: Grind kaolin to 200 mesh, add potassium carbonate solution twice the weight of kaolin to kaolin, the mass concentration is 30mg / L, stir evenly, heat to 170°C at 3°C / min, and keep warm for 15min , then add methacryloxypropyltrimethoxysilane with 1.6% weight of kaolin, mix evenly, heat slowly to 260°C, keep stirring for 30min, it can fully modify kaolin, improve the cohesiveness of kaolin, and make Kaolin can be fully mixed and bonded with resin to improve the strength and flame retardancy of exterior wall decorative panels, and obtain modified kaolin;

[0024] (2) Modification of waste tiles: crush waste tiles to 150 mesh, add 3-aminopropyltrimethoxysilane with a weight of 1.1% of the crushed material, stir evenly, heat to 130°C at a speed of 2°C / min, and keep warm for 30 minutes , natural cooling,...

Embodiment 2

[0031] A method for preparing a light-weight thermal insulation and flame-retardant exterior wall decorative board, comprising the following steps:

[0032] (1) Kaolin modification: crush kaolin to 250 mesh, add potassium carbonate solution 2.5 times the weight of kaolin to kaolin, the mass concentration is 33mg / L, stir evenly, heat to 190°C at 3.5°C / min, and keep warm for 18min , then add methacryloxypropyltrimethoxysilane with 1.7% weight of kaolin, mix evenly, heat slowly to 270°C, keep stirring for 35min, it can fully modify kaolin, improve the cohesiveness of kaolin, and make Kaolin can be fully mixed and bonded with resin to improve the strength and flame retardancy of exterior wall decorative panels, and obtain modified kaolin;

[0033] (2) Modification of waste tiles: crush waste tiles to 180 mesh, add 3-aminopropyltrimethoxysilane with a weight of 1.2% of the crushed material, stir evenly, heat to 160°C at a speed of 2.5°C / min, and keep warm for 35 minutes , natural co...

Embodiment 3

[0040] A method for preparing a light-weight thermal insulation and flame-retardant exterior wall decorative board, comprising the following steps:

[0041] (1) Kaolin modification: Grind kaolin to 300 mesh, add potassium carbonate solution 3 times the weight of kaolin to kaolin, the mass concentration is 35mg / L, stir evenly, heat to 200°C at 4°C / min, and keep warm for 20min , then add methacryloxypropyltrimethoxysilane with 1.8% weight of kaolin, mix evenly, heat slowly to 280°C, keep stirring for 40min, it can fully modify kaolin, improve the cohesiveness of kaolin, and make Kaolin can be fully mixed and bonded with resin to improve the strength and flame retardancy of exterior wall decorative panels, and obtain modified kaolin;

[0042] (2) Modification of waste tiles: crush waste tiles to 200 mesh, add 3-aminopropyltrimethoxysilane with a weight of 1.3% of the crushed material, stir evenly, heat to 190°C at a speed of 3°C / min, and keep warm for 40min , natural cooling, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com