Technology for producing formaldehyde through iron-molybdenum method

A production process and formaldehyde technology, which is applied in the field of French formaldehyde production process, can solve the problems of long catalyst supply cycle, cumbersome procedures, and high price, and achieve the effects of shortening the supply cycle, ensuring product quality, and short supply cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

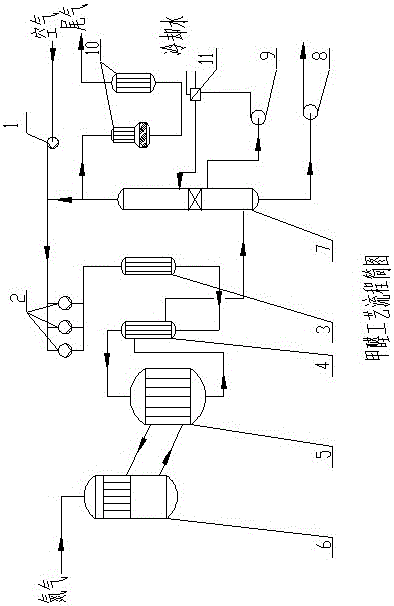

[0021] Refer to attached figure 1 , this embodiment includes sequentially connecting an air filter (1), a booster fan (2), a circulation fan (3), a methanol preheater (4), a methanol vaporizer (5), a formaldehyde reactor (6), and a formaldehyde Absorption tower (8), heat transfer oil condenser (7) and ECS tail gas treatment system (11);

[0022] (a). Raw air first enters the air filter, booster fan, and circulation fan in sequence to remove mechanical impurities, then enters the methanol preheater, and is heated by the dilute formaldehyde from the middle section of the formaldehyde absorption tower (8) before entering the methanol vaporizer , is heated by gas-phase formaldehyde from the formaldehyde reactor and then sent to the formaldehyde reactor;

[0023] (b). After the reaction in the iron-molybdenum catalyst bed of the formaldehyde reactor, it enters the shell side of the methanol vaporizer to vaporize the methanol, cools down the formaldehyde gas, and then enters the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com