Electromagnetic shielding coating for electronic components, and preparation method thereof

A technology for electromagnetic shielding coatings and electronic components, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor heat dissipation, unreasonable component distribution ratio, complex formula, etc., to achieve good heat dissipation effect, components and distribution than reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

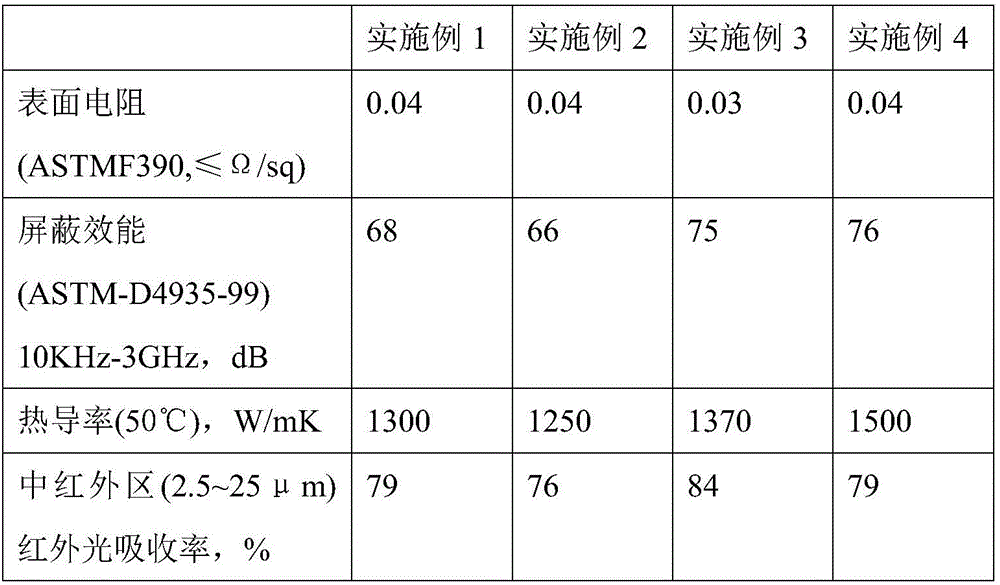

Examples

Embodiment 1

[0024] 30 parts of water-based polyurethane emulsion, 5 parts of surface hydroxylated carbon nanotubes, 2 parts of graphene, 5 parts of beryllium oxide, 3 parts of boron nitride, 1 part of bentonite, 1.1 parts of auxiliary agent, 20 parts of water, and 6 parts of curing agent.

[0025] The curing agent of the present invention is triethylenetetramine.

[0026] The auxiliary agent comprises 0.1 part of polyphosphate, 0.2 part of silylsilane, 0.3 part of polyether modified polydimethylsiloxane, and 0.5 part of tri-n-butyl citrate in parts by weight.

[0027] The water-based polyurethane emulsion is an alkyl-hydroxy silicone oil-modified water-based polyurethane. The preparation method is as follows: by weight, 10 parts of TDI, 8 parts of polyether, 8 parts of DMPA, and 10 parts of alkyl-hydroxy silicone oil are mixed uniformly, and the temperature is raised to 70°C, Add 0.5 part of organotin catalyst to react for 3h, then add 5 parts of chain extender to react for 1h, then add acetone ...

Embodiment 2

[0032] 50 parts of water-based polyurethane emulsion, 8 parts of surface hydroxylated carbon nanotubes, 4 parts of graphene, 8 parts of beryllium oxide, 5 parts of boron nitride, 3 parts of bentonite, 2.2 parts of additives, 40 parts of water, and 10 parts of curing agent.

[0033] The auxiliary agent comprises 0.5 parts by weight of polyphosphate, 0.4 parts of silylsilane, 0.5 parts of polyether modified polydimethylsiloxane, and 0.8 parts of tri-n-butyl citrate.

[0034] The water-based polyurethane emulsion is an alkyl-hydroxy silicone oil modified water-based polyurethane. The preparation method is as follows: in parts by weight, 30 parts of TDI, 20 parts of polyether, 16 parts of DMPA, and 18 parts of alkyl-hydroxy silicone oil are mixed uniformly, heated to 90°C, and added 0.5~3 parts of organotin catalyst are reacted for 6h, then 10 parts of chain extender are added for reaction for 3h, then acetone is added to dilute the reactant, after cooling, add triethylamine to neutrali...

Embodiment 3

[0039] 40 parts of water-based polyurethane emulsion, 6 parts of surface hydroxylated carbon nanotubes, 3 parts of graphene, 6 parts of beryllium oxide, 4 parts of boron nitride, 2 parts of bentonite, 1.5 parts of additives, 30 parts of water, 8 parts of curing agent.

[0040] The auxiliary agent comprises 0.2 parts of polyphosphate, 0.3 parts of silyl silane, 0.4 parts of polyether modified polydimethylsiloxane, and 0.6 parts of tri-n-butyl citrate by weight.

[0041] The water-based polyurethane emulsion is an alkyl-hydroxy silicone oil modified water-based polyurethane, and the preparation method is as follows: by weight, 20 parts of TDI, 12 parts of polyether, 12 parts of DMPA, and 14 parts of alkyl-hydroxy silicone oil are mixed uniformly, and the temperature is raised to 80°C, Add 1 part of organotin catalyst to react for 4h, then add 6 parts of chain extender to react for 2h, then add acetone to dilute the reactant, add triethylamine to neutralize the salt after cooling down,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap