Edge cutting woven label and preparation method thereof

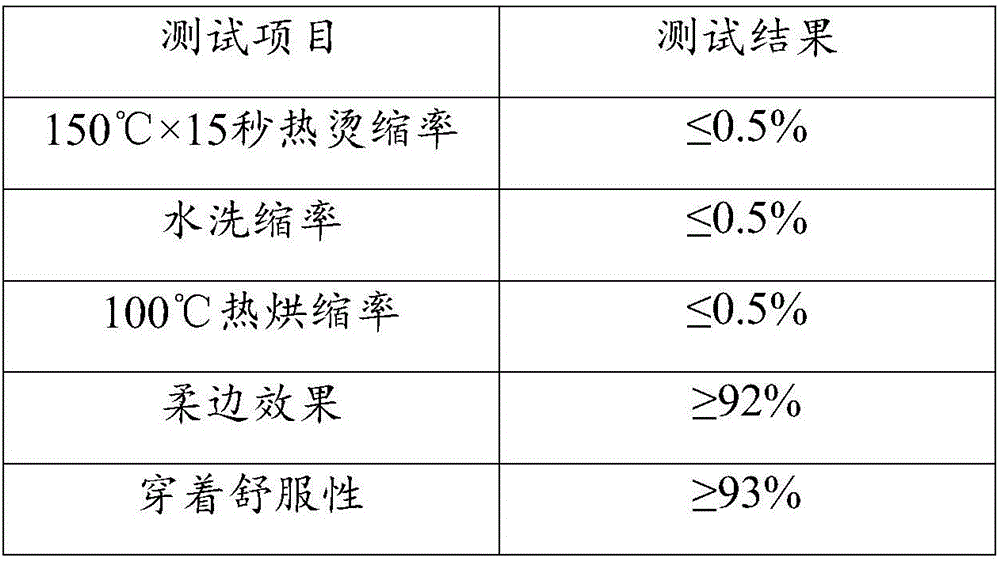

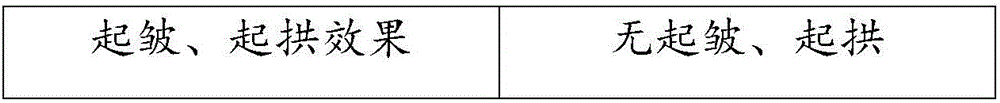

A technology of trimming and weaving labels, which is applied in the direction of textile, fabric, textiles and papermaking, etc. It can solve the problems of inconvenient mechanical positioning of garment factories, increased difficulty of production, poor dimensional stability and other problems, and achieves pattern color Rich, productive, less wrinkling and bowing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of polyester woven label of the present embodiment comprises the following steps:

[0040] (1) The weft yarn is made of cotton-like hollow polyester fiber 75D, and is dyed to the required color by using a package dyeing machine.

[0041] (2) Add the hydrophilic silicone softener Goon820 2.5g / L (from Huntsman Chemical) to the package dyeing machine for the obtained weft yarn, run at 45°C for 25 minutes, drain, dehydrate, and dry.

[0042](3) When designing the woven label structure, the weft yarn is mixed with the cotton yarn, and the weight ratio of the cotton yarn is 25%; Edge design: at the tangent line, the floating length of warp yarns and weft yarns interlaced is set to 2, and at the same time, 2 organization units are respectively set on both sides of the tangent line, and the floating lengths of warp yarns interlaced with weft yarns in the organization units are 2; Mark tightness reaches 4200.

[0043] (4) Carry out weaving accordin...

Embodiment 2

[0050] A kind of preparation method of polyester woven label of the present embodiment comprises the following steps:

[0051] (1) The weft yarn is made of cotton-like hollow polyester fiber 50D, and the dyeing machine is used to dye the desired color.

[0052] (2) Add the hydrophilic silicone softener Goon820 2.5g / L (from Huntsman Chemical) to the package dyeing machine for the obtained weft yarn, run at 50°C for 20min, drain, dehydrate and dry.

[0053] (3) When designing the woven label structure, the weft yarn is mixed with the cotton yarn, and the weight ratio of the cotton yarn is 35%; Side design (same as Example 1); woven label density reaches 4200.

[0054] (4) Carry out weaving according to the above-mentioned woven label structure to obtain a pre-finished woven label; the weaving process is as follows: the temperature of the woven label is 135°C, and the tension of the woven label is 45G.

[0055] (5) Cut and divide the above woven label pre-finished products with...

Embodiment 3

[0061] A kind of preparation method of polyester woven label of the present embodiment comprises the following steps:

[0062] (1) The weft yarn is made of cotton-like hollow polyester fiber 50D, and the dyeing machine is used to dye the desired color.

[0063] (2) Add the hydrophilic silicone softener Goon820 3.0 g / L (from Huntsman Chemical) to the package dyeing machine, run at 40°C for 30 minutes, drain, dehydrate and dry.

[0064] (3) When designing the woven label structure, mix the weft yarn with the cotton yarn, wherein the weight ratio of the cotton yarn is 20%; Edge (same as Example 1); the density of the woven label reaches 4200.

[0065] (4) Carry out weaving according to the above-mentioned woven label structure to obtain a pre-finished woven label; the weaving process is as follows: the temperature of the woven label is 120°C, and the tension of the woven label is 30G.

[0066] (5) Cut and divide the above-mentioned woven label pre-finished products with an ultr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com